Machining tool device used for automobile rocker arm

A technology for automobiles and tooling, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems affecting processing quality, poor economic effect, troublesome operation, etc., to improve the fixing effect, improve product quality, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

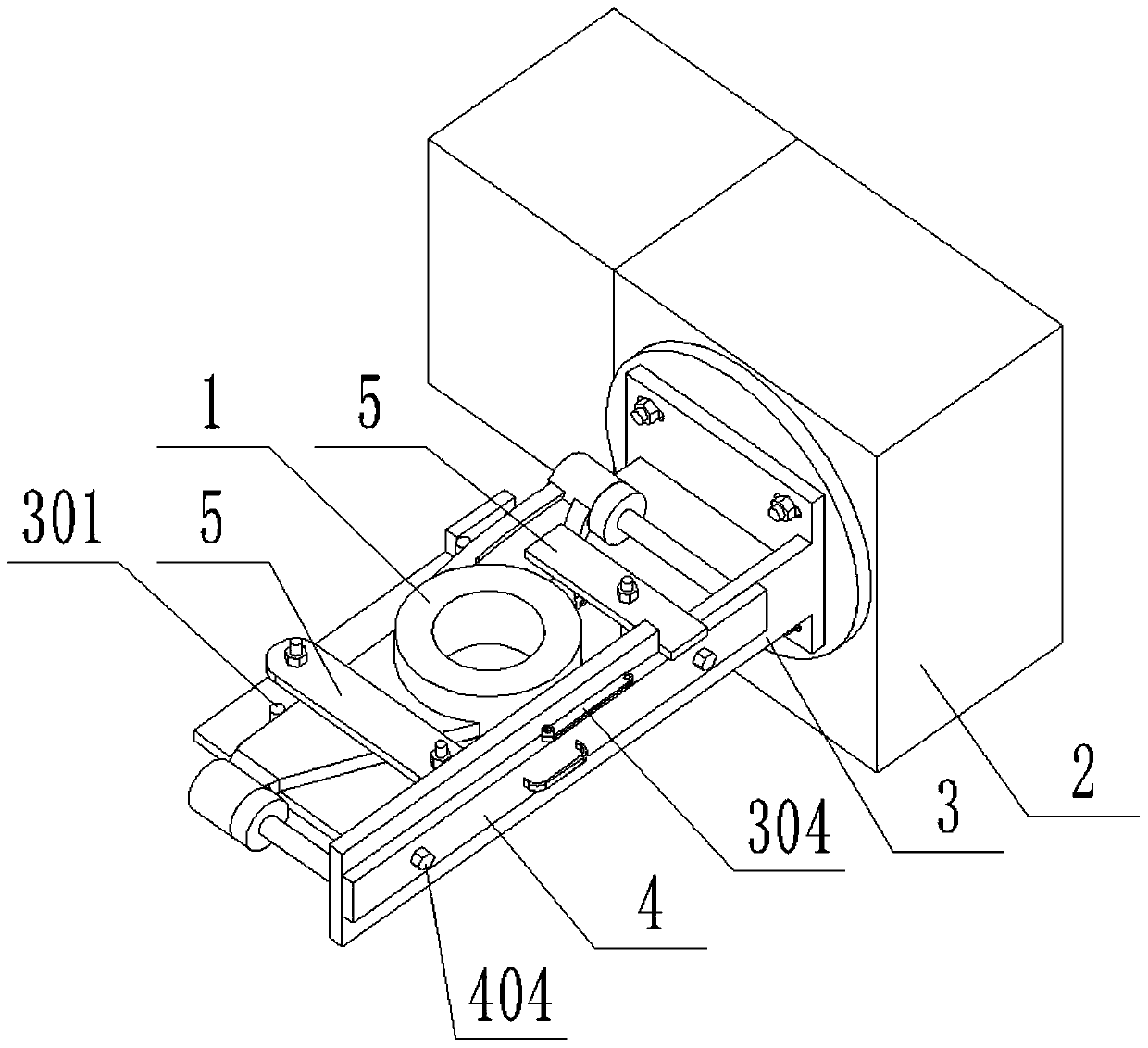

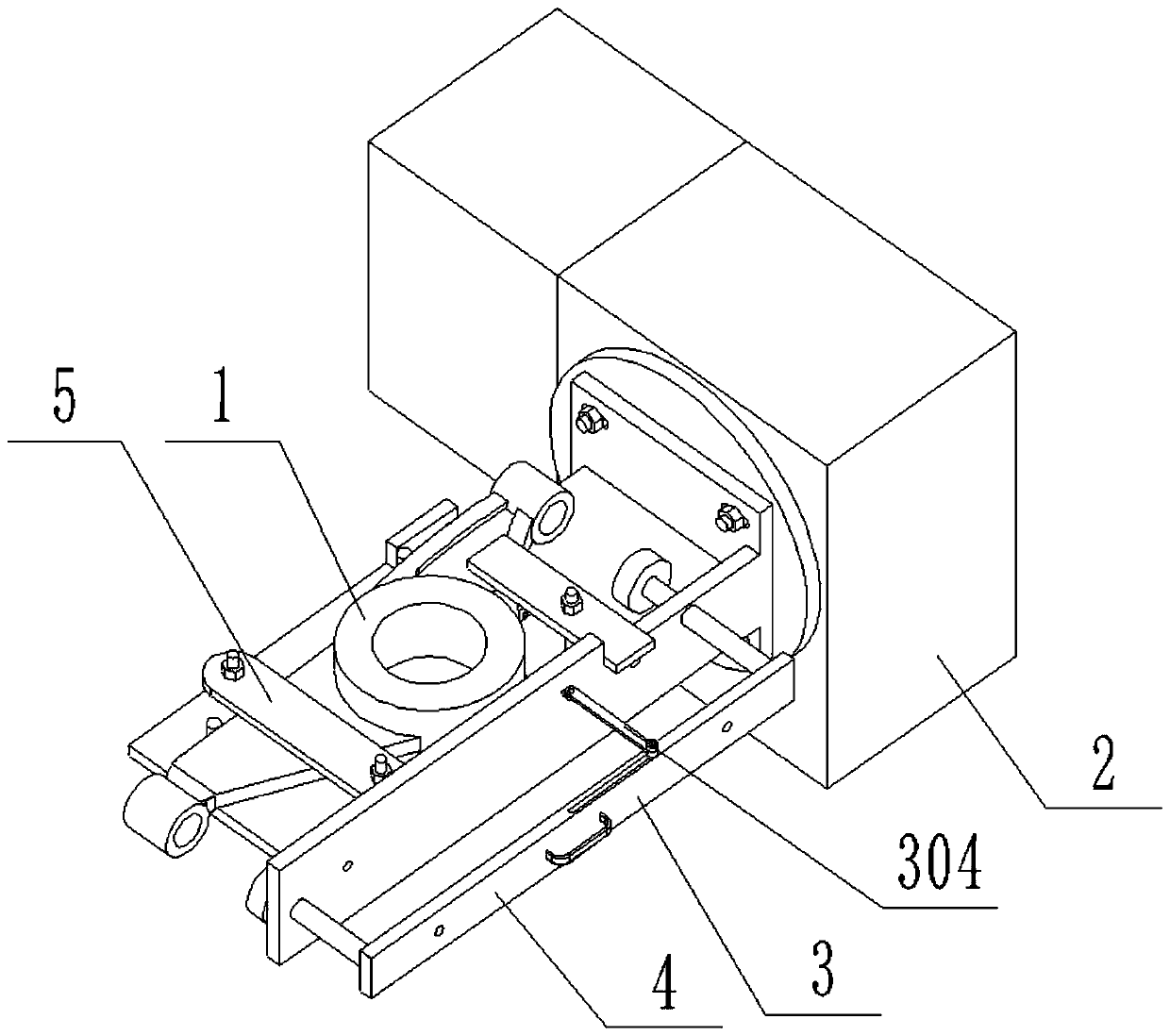

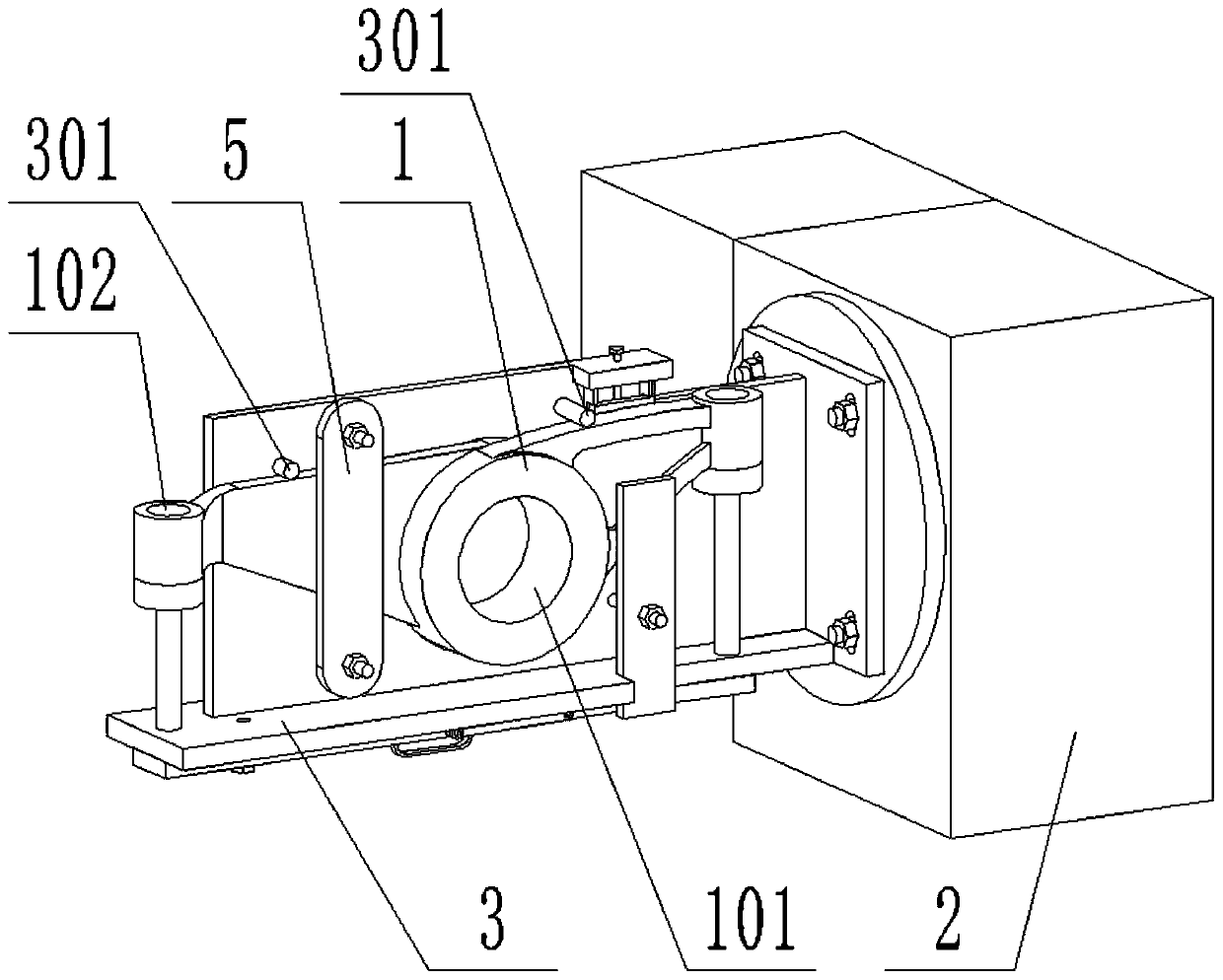

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a processing tooling device for a rocker arm of an automobile, including: a rocker arm 1, a rotating hole 101, a connecting hole 102, an indexing rotary table 2, a bracket 3, a positioning column 301, an upper wedge 302, and a lower wedge 303 , connecting rod 304, rocker arm process hole 305, auxiliary plate 4, circular rail 401, support platform 402, chute 403, fastening bolt 404 and pressure plate 5; a group of brackets are fastened on the rotating disk of the indexing rotary table 2 3; the upper end surface of the support 3 is pressed by two sets of pressure plates 5 to form a set of rocker arms 1; the front end of the support 3 is slidably connected to a set of auxiliary plates 4 and is fastened to the support 3 through two sets of fastening bolts 404; the rocker arm 1 A group of rotating holes 101 are arranged in the middle of the rocker arm 1; a group of connecting holes 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com