Workpiece non-rotating excircle machining mechanism

A technology for processing mechanisms and workpieces, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as large mechanical vibration, high energy consumption, and the influence of workpiece accuracy and surface roughness, and achieve large machine tool losses. , The effect of high machining accuracy and low power consumption of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

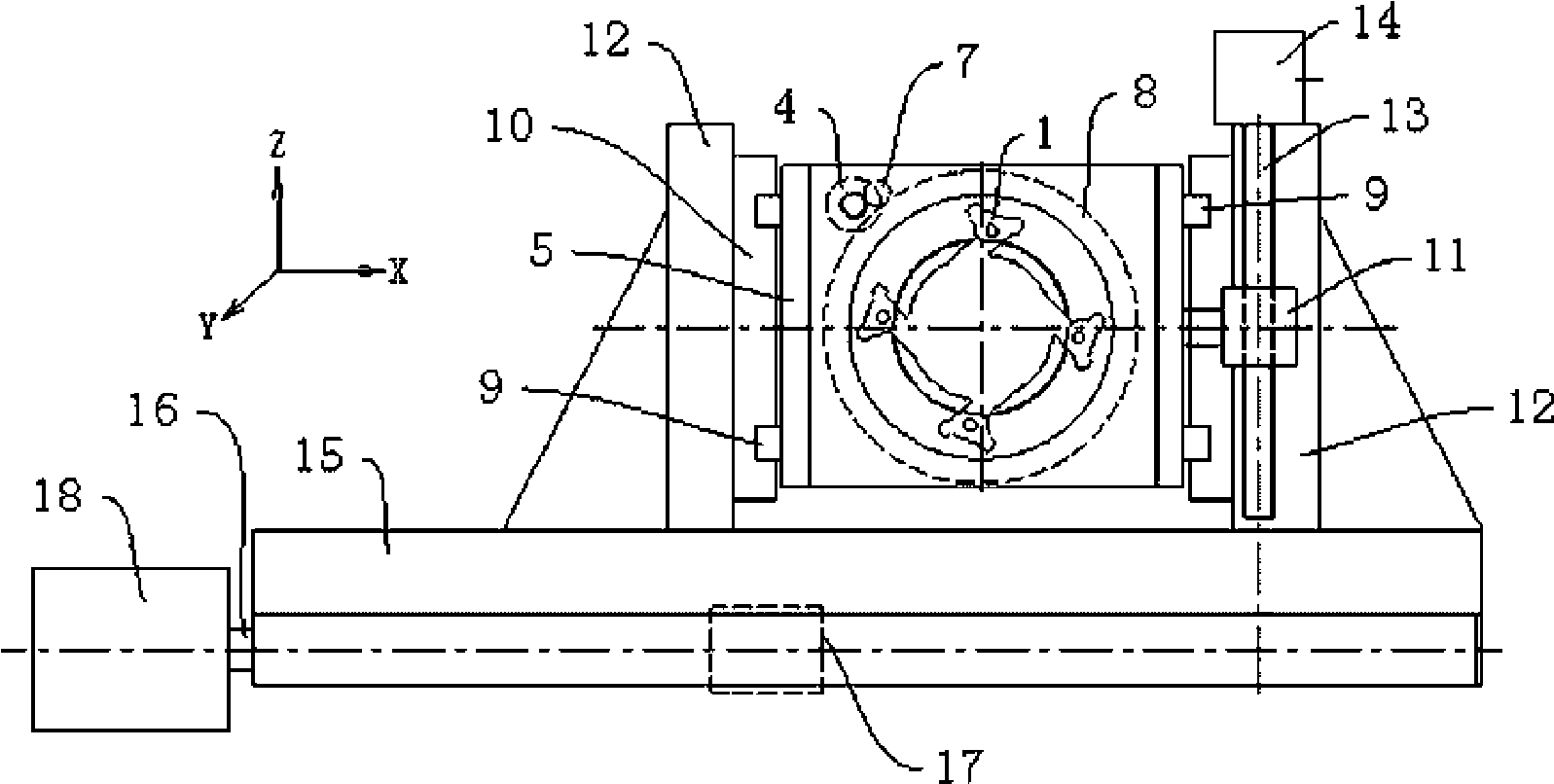

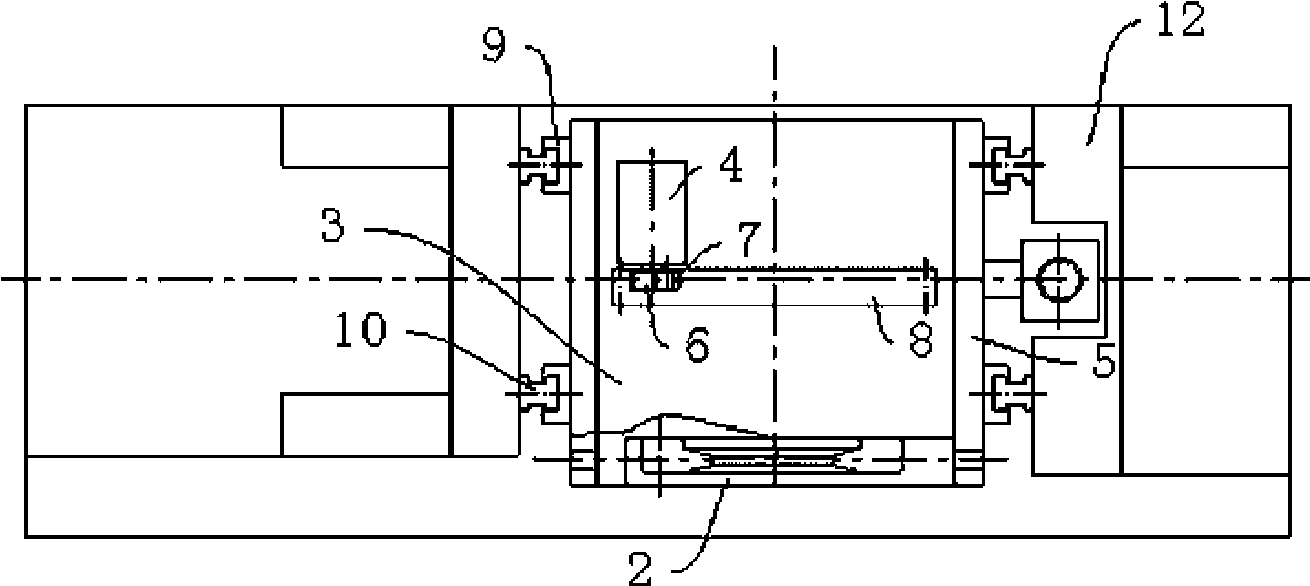

[0010] figure 1 , 2 The shown workpiece does not rotate the outer circle processing mechanism. Four inner whirlwind milling cutters 1 are fixed on the inner circumference of the milling cutter fixing sleeve 2 extending along the y-axis direction (the movement direction of the large carriage of the machine tool). The inner whirlwind milling cutter 1 and the milling cutter Cutter holder 2 has constituted the inner cyclone milling head. The milling cutter fixed sleeve is rotatably connected on the support base 3, and the main motor 4 and the support base 3 are fixed on the slide plate 5. The motor gear 6 of the main motor 4 meshes with the bridge gear 7 , the bridge gear 7 meshes with the bull gear 8 , and meshes with the outer periphery of the milling cutter fixed sleeve 2 . The main motor 4 rotates, and the milling cutter fixed sleeve 2 and the inner cyclone milling cutter 1 are driven to rotate around the y-axis in the xoz plane through the motor gear 6, the bridge gear 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com