Clamping device for medical instrument machining

A technology for clamping devices and medical devices, which is applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of large shaking range of clamping devices, affecting processing accuracy, inconvenience, etc., and achieves reasonable structure and layout of the device. The effect of reducing the vibration amplitude and excellent shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

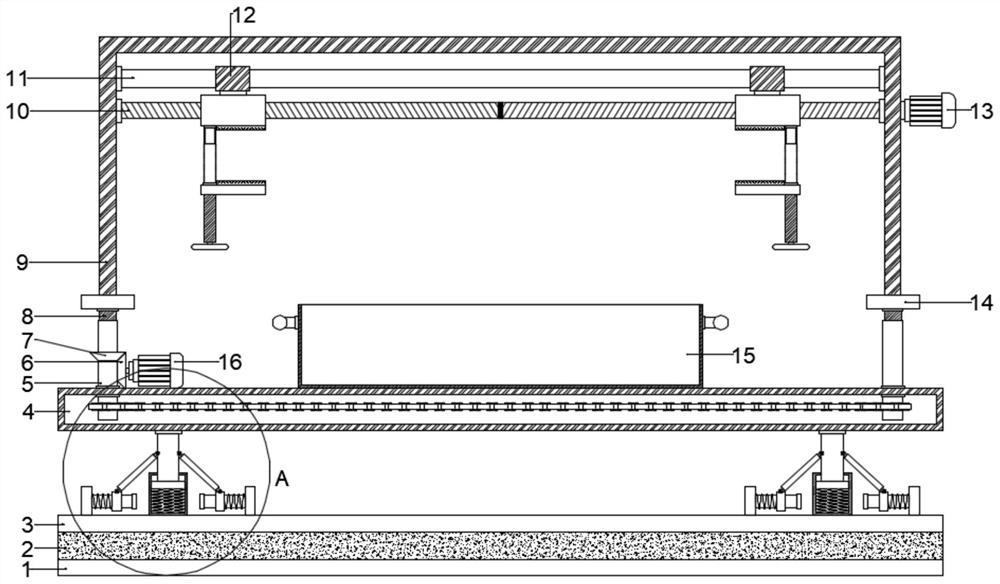

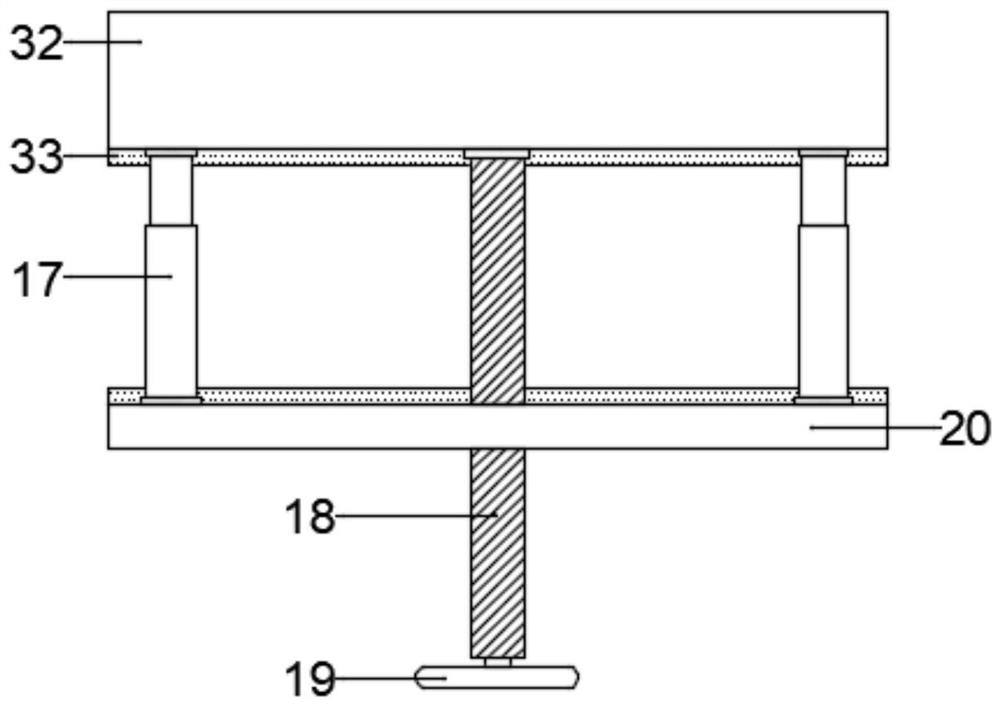

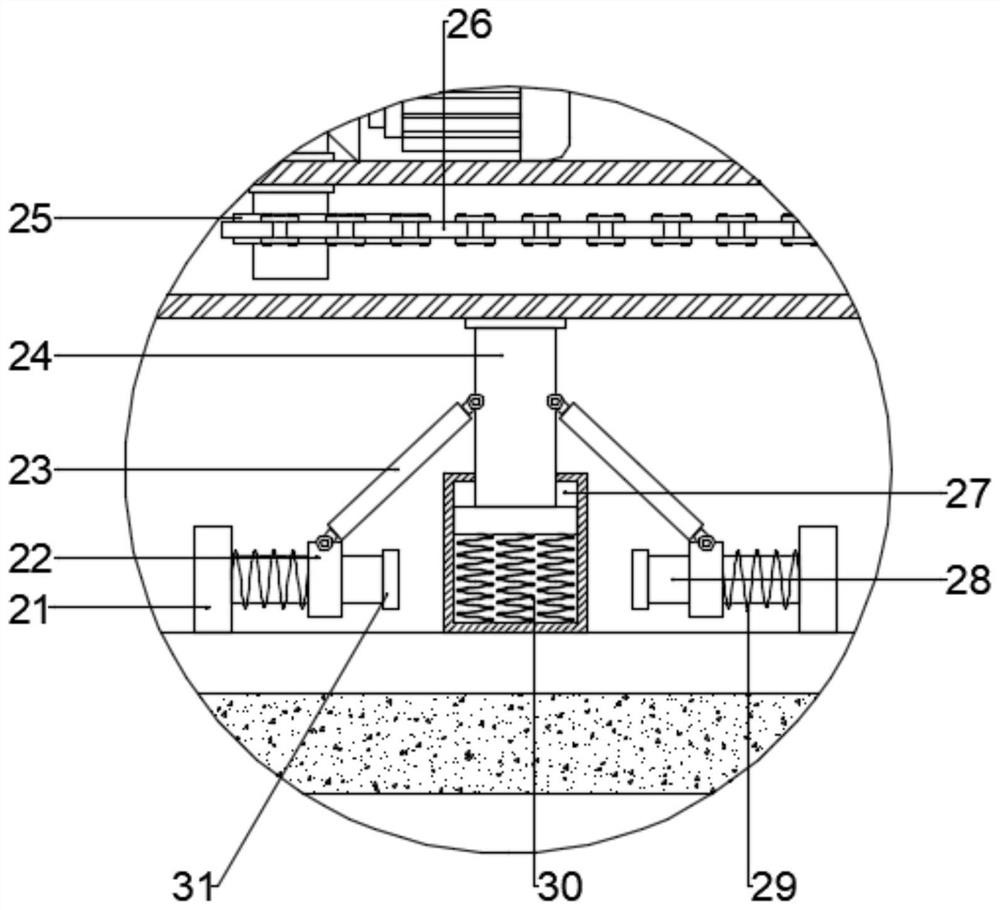

[0022] see Figure 1~3 , in an embodiment of the present invention, a clamping device for medical device processing, comprising a bearing platform 4, a U-shaped plate 9, a shock absorbing unit and a clamping unit, the U-shaped plate 9 is arranged above the bearing platform 4, and the U-shaped There is a lifting assembly between the plate 9 and the loading platform 4. The purpose of setting the lifting assembly is to facilitate the user to adjust the processing area of the parts clamped by the device to a height that is convenient for operation and processing. The clamping unit is located on the U-shaped plate. 9, the damping unit is located at the lower part of the bearing platform 4.

[0023] Lifting assembly comprises two bar-shaped seats 14, and two described bar-shaped seats 14 are respectively arranged on the bottom of U-shaped plate 9, and carrying platform 4 is positioned at the area below two bar-shaped seats 14 and is equidistant from front to back. A plurality of ...

Embodiment 2

[0031] see Figure 4 The difference between this embodiment of the present invention and Embodiment 1 is that further, in order to facilitate the movement of the device, a plurality of moving wheels 34 are symmetrically arranged at the bottom of the shock-absorbing base, and the moving wheels 34 are self-locking rollers. The device can be moved easily and conveniently through the moving wheels 34, which saves time and effort, and is convenient and practical.

[0032] The working principle of the present invention is: when the present invention is in use, the parts are first clamped and fixed by the clamping unit, and then the parts to be processed are adjusted to a height position convenient for operation and processing by the lifting assembly, and then the parts can be processed During the processing operation, the shock absorbing unit can effectively damp the device and greatly reduce the overall shaking range during processing, so as to avoid affecting the processing accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com