Screw lubrication detecting device for numerical control machine tool

A detection device, a technology of CNC machine tools, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of inability to supply, influence of lead screws, influence of positioning accuracy of machine tools, etc., to achieve simple structure and avoid friction heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

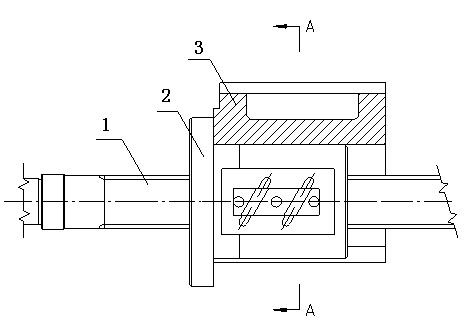

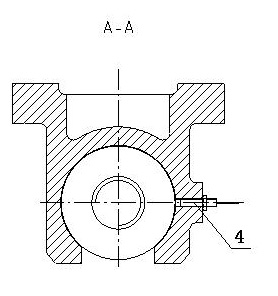

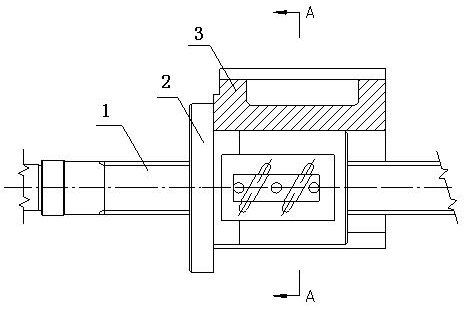

[0012] in figure 1 , figure 2 Among them, the present invention is provided with a lead screw 1, a screw frame nut seat 3 and a lead screw nut 2 are sleeved on the lead screw 1, a temperature sensor 4 is embedded on the lead screw nut 2, and the temperature sensor 4 is controlled by an AD converter and programmable logic The device is electrically connected. Temperature sensor 4 is a PT100 temperature sensor with a certain functional relationship between resistance and temperature. Through an AD converter, the analog signal sampled by the temperature sensor is converted into a digital signal and sent to the programmable logic controller. The CNC system PLC is programmed according to the A good program calculates the temperature value, compares whether the temperature is higher than the normal operating temperature of the machine tool screw, to judge whether the lubricating oil supply of the machine tool screw is normal, and displays alarms and prompts on the system display acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com