Large-scale numerical control machine tool fault monitoring system based on multi-sensor

A CNC machine tool and multi-sensor technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as monitoring and analysis of difficult tool wear conditions, affecting the machining accuracy of CNC machine tools, and difficult CNC machine tool changing conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

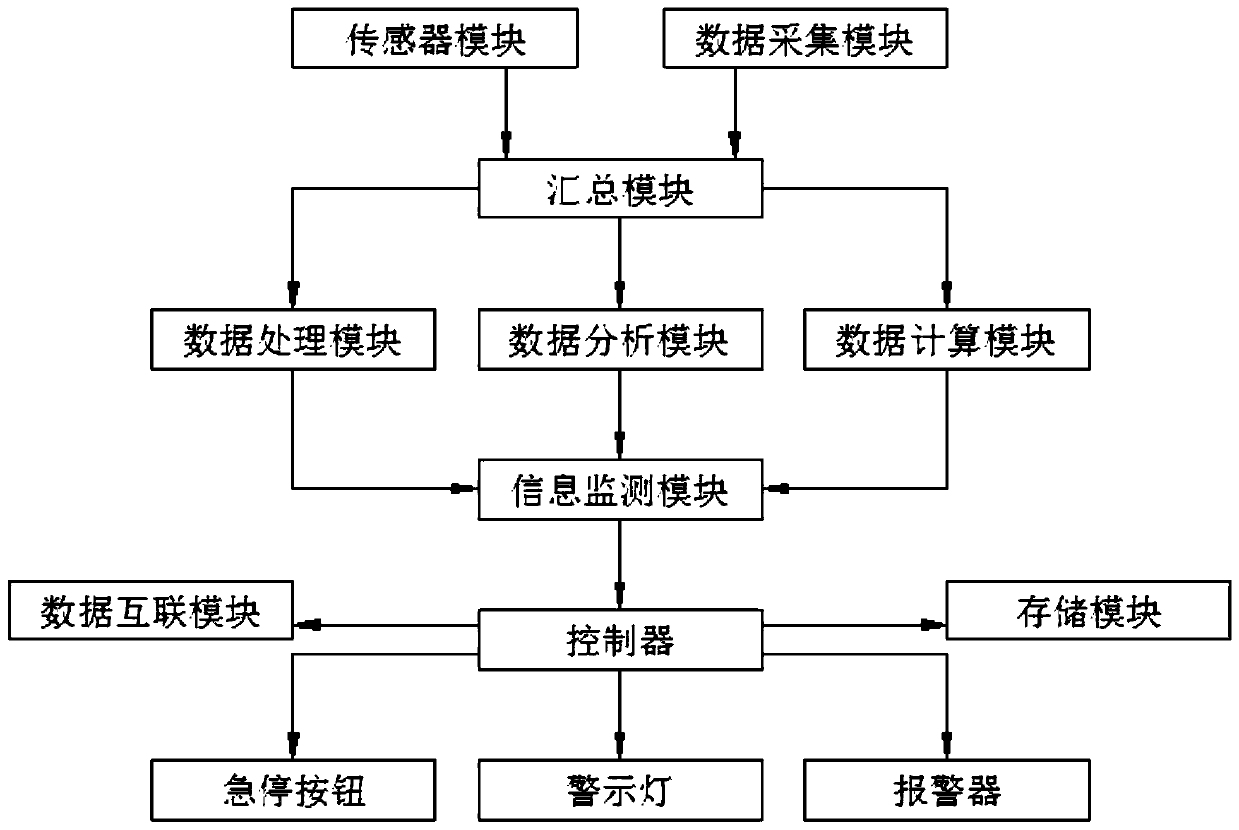

[0039] like figure 1 As shown, a large-scale CNC machine tool fault monitoring system based on multi-sensor, including sensor module, data acquisition module, summary module, data analysis module, information monitoring module, controller, data interconnection module, storage module, data processing module, emergency Stop button, alarm, data calculation module and warning lights;

[0040] The sensor module is used for sensors to collect data information, and the sensors include temperature sensors, rotational speed sensors and voltage sensors, the sensor module is used to transmit the collected data information to the summary module; Work information, and the work information includes the working time of the tool, the number of times the tool is used, the tool change time of the tool disc, and the number of tools that the tool disc passes through when changing the tool. The data acquisition module is used to transmit the collected work information to A summary module; the sum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com