Numerical control processing fixture for two perpendicularly-crossed shafts

A vertical intersection and fixture technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of small use range, long manufacturing cycle, complex structure, etc., to improve processing quality, save costs, and achieve obvious effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

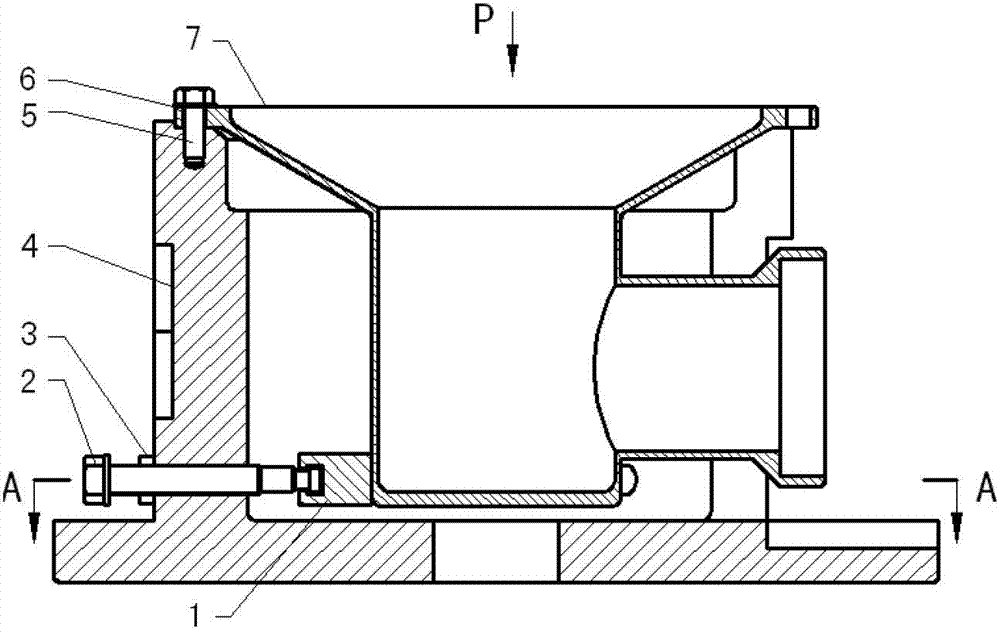

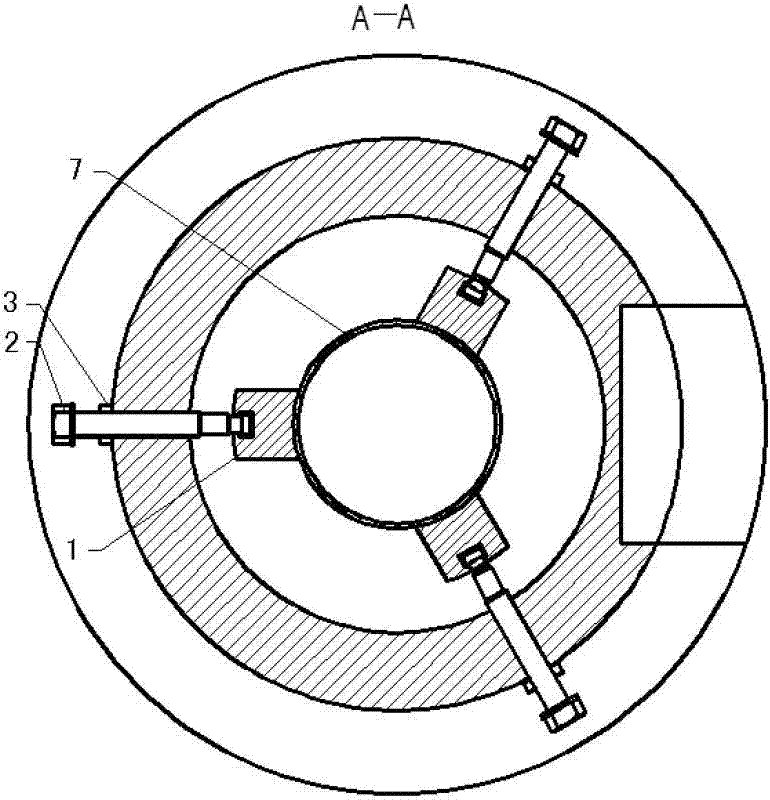

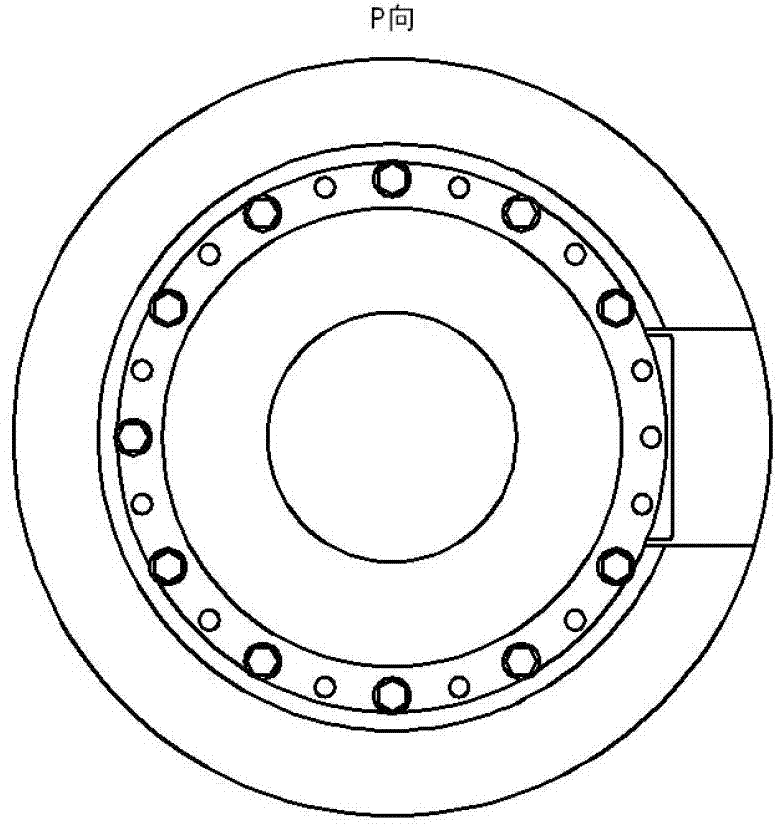

[0031] This embodiment is a machining fixture for two perpendicularly intersecting axes. The vertically intersecting axes include a first axis with a vertical axis and a second axis with a horizontal axis, and the first and second axes are perpendicular to each other and intersect. The clamp includes a compression block 1 , an adjustment screw 2 , a stop nut 3 , a fixed support 4 , a compression screw 5 and a washer 6 .

[0032] Fixed support 4 is the tube shape that one end that 45# steel is made has end cap. The workpiece 7 is located in this fixed support 4 . The inner hole of the fixed support 4 is a stepped hole, and the step surface at the upper end of the inner hole of the fixed support 4 is the positioning notch of the workpiece, and the inner diameter of the positioning notch is consistent with the diameter of the workpiece positioning surface. The diameter of the middle section of the inner hole of the fixed support 4 is 30 mm larger than the sum of the outer diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com