Separator for horizontally rotating shuttle of sewing machine and regulating method thereof

A sewing machine and separator technology, which is applied in the direction of sewing equipment, sewing machine components, sewing machine ring mechanism, etc., and can solve problems such as difficulty in inserting a feeler gauge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] (horizontal hook of a sewing machine)

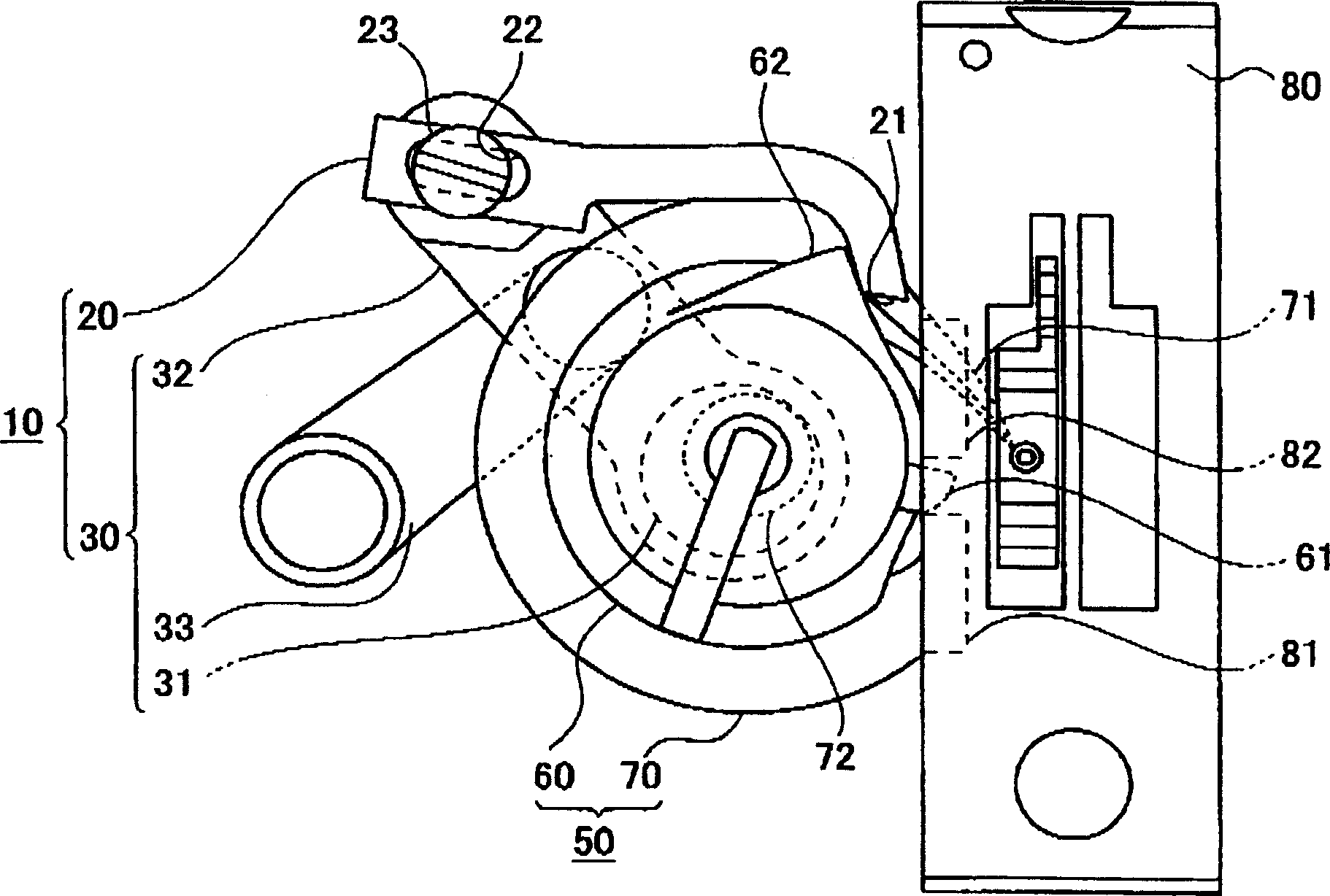

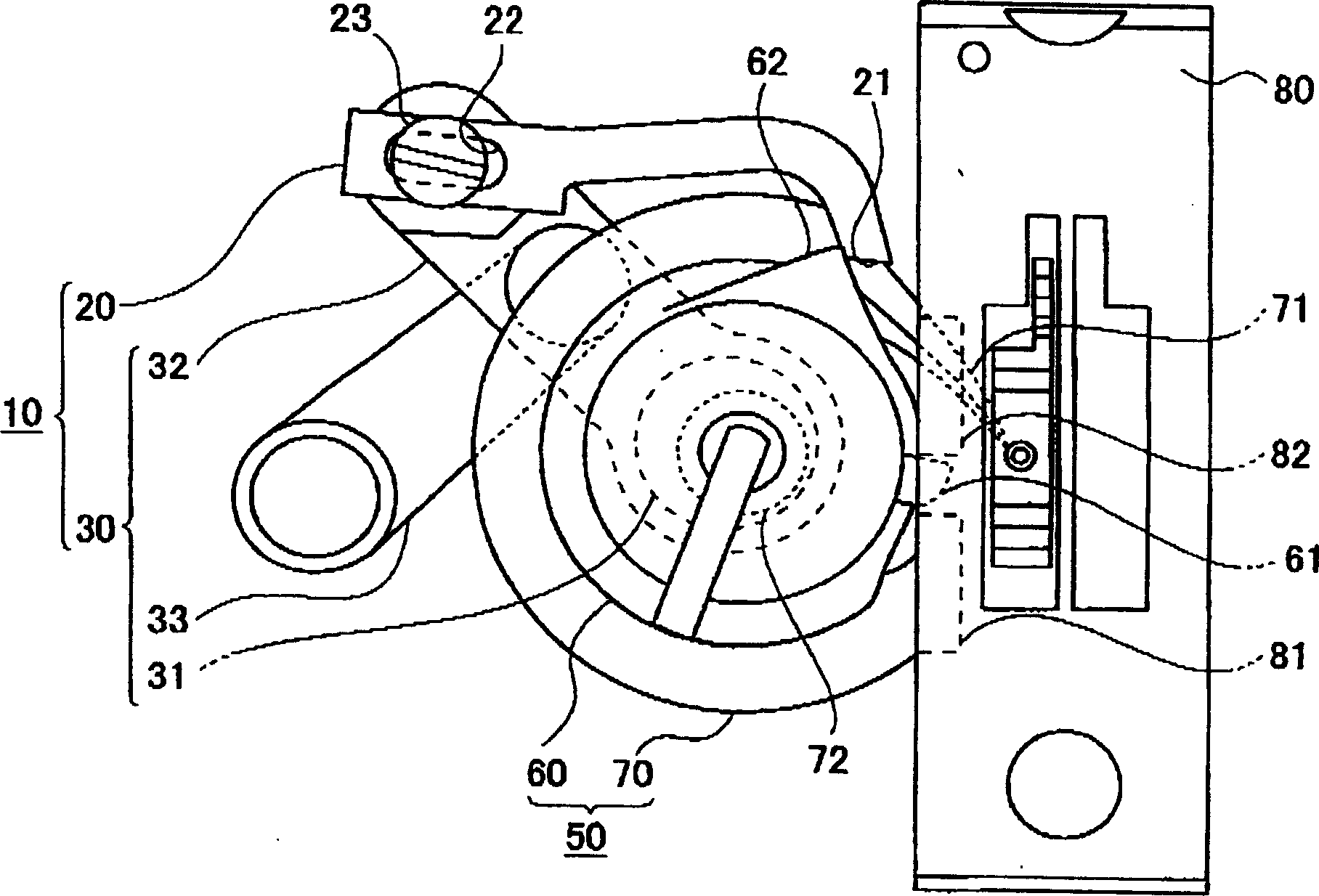

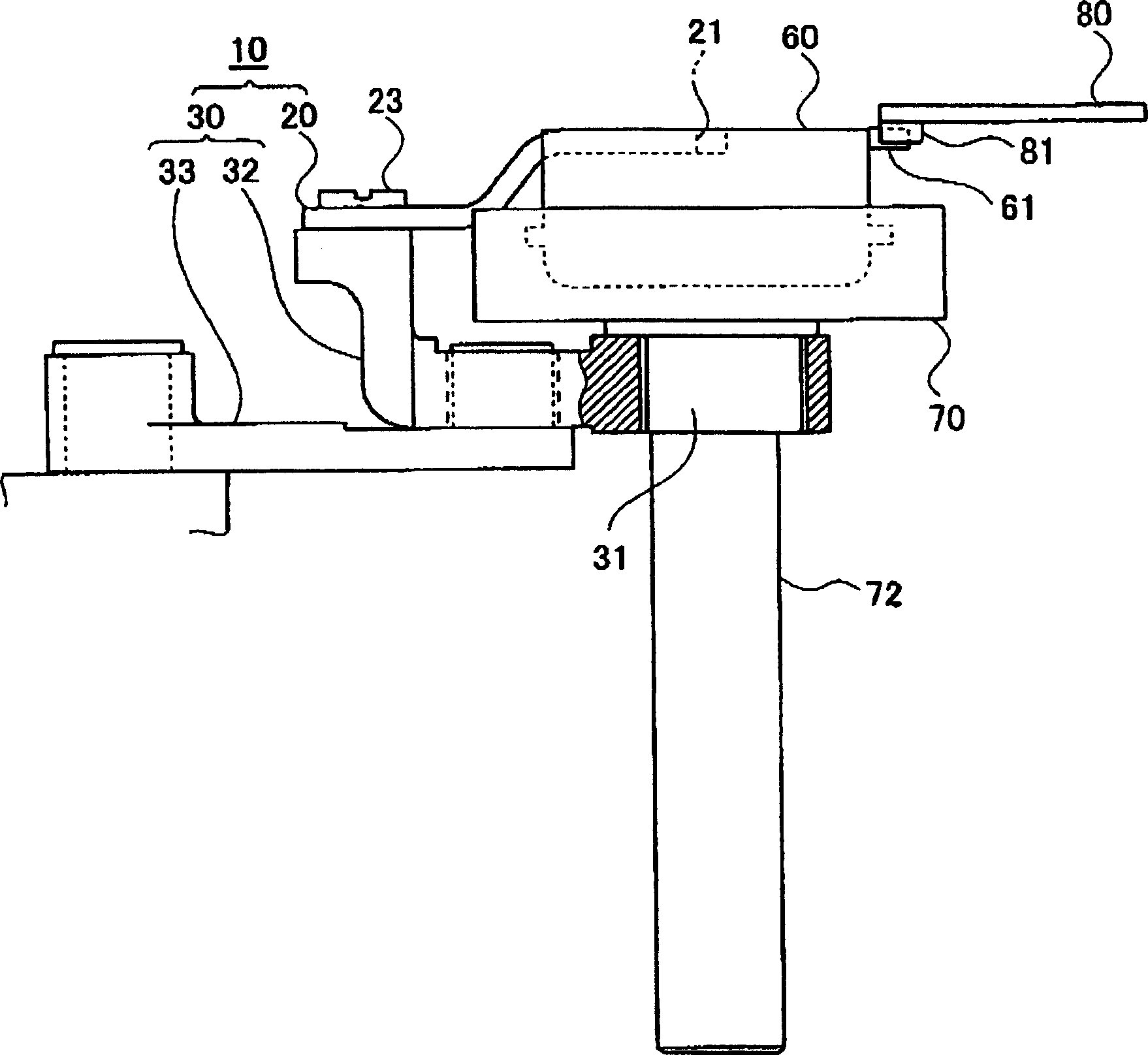

[0041] refer to figure 1 ~ Fig. 6 illustrates the separator 10 of the horizontal rotary hook 50 of the sewing machine according to the embodiment of the present invention. figure 1 and figure 2 It is a top view of the horizontal rotary hook 50 and the separator 10 of the sewing machine, image 3 It is a front view of the horizontal hook 50 and the separator 10 of the sewing machine.

[0042] The above-mentioned sewing machine horizontal rotary hook 50 is arranged under the needle plate 80 of the sewing machine, and has the function of catching the upper thread from the needle inserted into the needle hole of the needle plate 80 during sewing to form a thread loop and to drill the lower thread into the upper thread loop. function.

[0043] And, in order to realize above-mentioned function, above-mentioned sewing machine horizontal rotary hook 50, as Figure 1 ~ Figure 3 As shown, it has: an inner hook 60 equipped with a bobbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com