Machine tool for producing shaft parts

A technology for shaft parts and processing machine tools, applied in the field of shaft parts production equipment, can solve problems such as shaft processing deformation and affecting processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

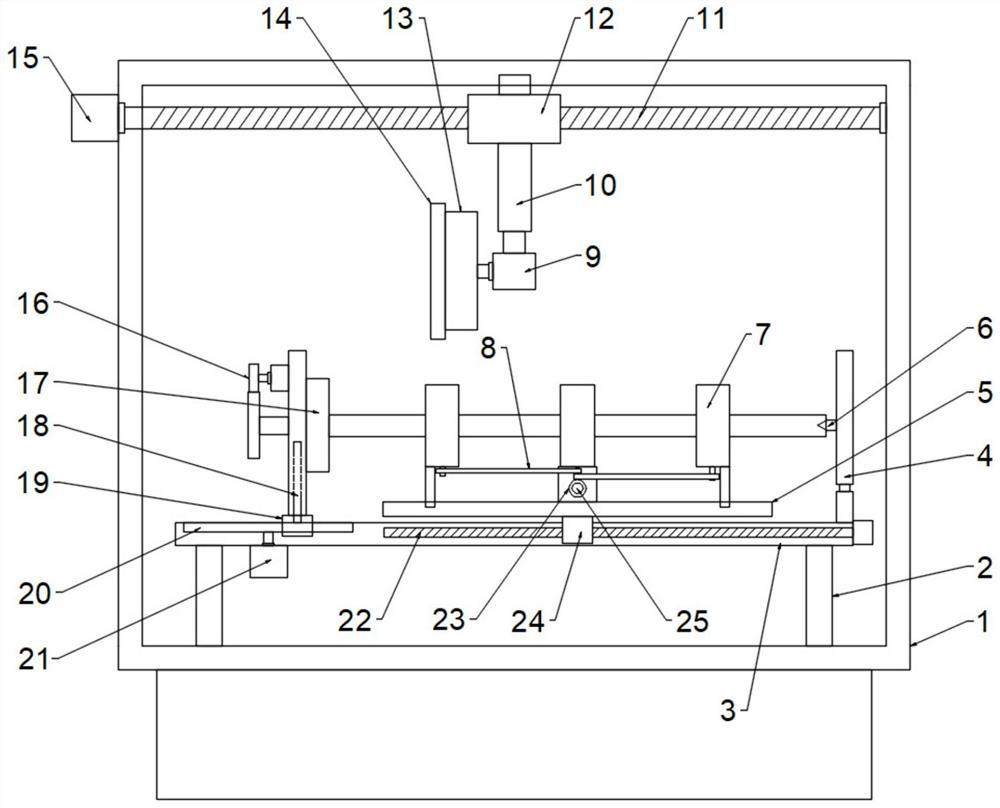

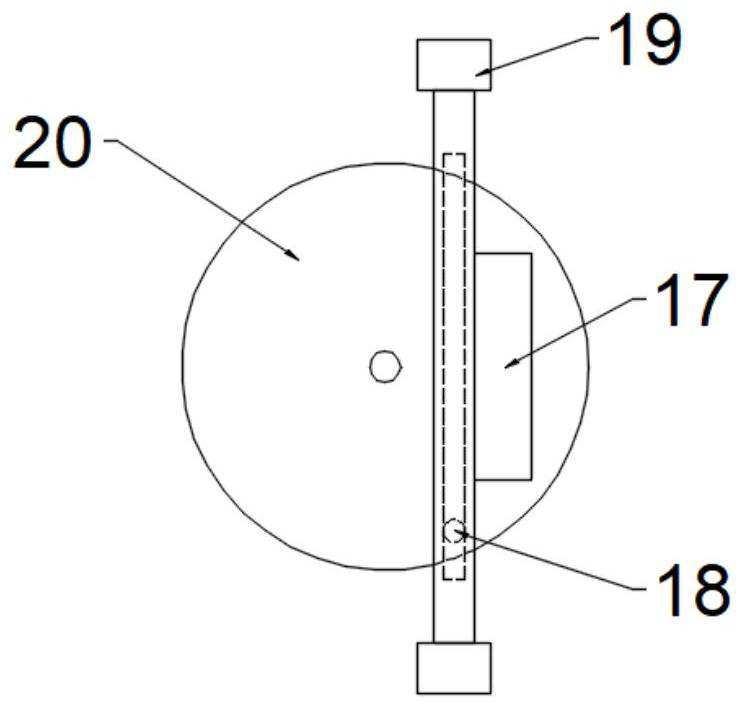

[0059] Embodiments of the present invention provide a processing machine tool for the production of shaft parts, such as figure 1 As shown, it includes a frame 1, a workbench 3 and a fixture unit, and the workbench 3 is installed on the frame 1. In this embodiment, preferably, the workbench 3 is connected to the frame 1 through a plurality of spaced support rods 2. Fixed connection, the two ends of the support rod 2 can be respectively fixed with the frame 1 and the workbench 3 by welding, and the clamp unit is installed on the workbench 3 for clamping both ends of the shaft. Specifically, the clamp unit includes:

[0060] The chuck assembly on the table 3 is used to fix one end of the shaft;

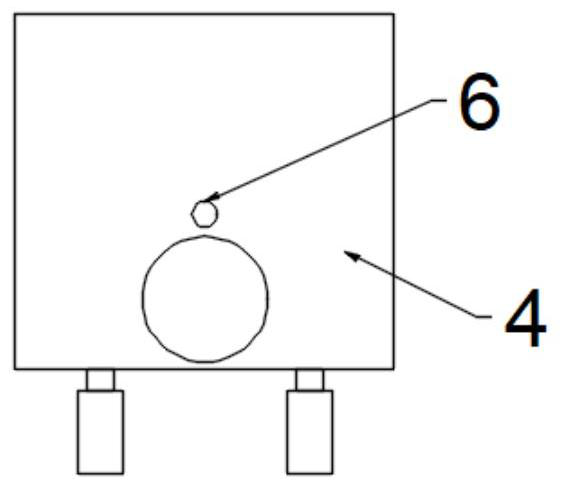

[0061] The top assembly on the table 3 is used to fix the other end of the shaft;

[0062] The processing machine tool for the production of shaft parts also includes a support unit installed on the worktable 3, and the support unit includes:

[0063] A mounting plate 5 arranged above...

Embodiment 2

[0090] In specific implementation, as figure 1 and Figure 8 As shown, the processing machine tool for the production of shaft parts also includes a processing unit installed on the frame 1 and located above the worktable 3, and the processing unit includes:

[0091] For the second motor 9, a mounting shell 13 is fixed on the output shaft of the second motor 9, and a grinding disc 14 is fixedly mounted on the side wall of the mounting shell 13 away from the second motor 9. The size of the grinding disc 14 shown is larger than The size of the mounting shell 13, the grinding disc 14 can be fixedly connected with the mounting shell 13 by screws, and the mounting shell 13 is driven by the second motor 9 to drive the grinding disc 14 to rotate, so that the shaft surface can be ground;

[0092]A plurality of second electric push rods 35 are fixedly installed in the mounting shell 13 at circumferential intervals, and the telescopic end of each second electric push rod 35 is installe...

Embodiment 3

[0095] The difference between this embodiment and Embodiment 2 is that a chip cleaning unit 36 is further included, and the chip cleaning unit 36 includes:

[0096] A support rod 2 hinged at one end of the workbench 3, the support rod 2 is fixed on the frame 1;

[0097] The third connecting rod 38 is hinged at the other end of the table 3, the third connecting rod 38 is eccentrically hinged with the disk 39, the disk 39 is fixed on the output shaft of the sixth motor, and the sixth motor is fixed on the frame 1, The six motors drive the disc 39 to rotate, the disc 39 drives the third link 38 to move, and the third link 38 drives the worktable 3 to reciprocate and tilt to swing, which helps the debris on the worktable 3 to fall from the worktable 3 and avoids breaking. Chip accumulation affects the machining quality and the life of machine components;

[0098] a plurality of second hemispheres protruding on the end face of the disc 39 close to the third connecting rod 38 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com