Floating flashboard machine and large area ultra-weak foundation fast directly draining concretion method

A plug-in machine and plug-in technology, which are applied in the fields of highway and bridge engineering, port engineering, and construction engineering, can solve the problems of difficult construction operation, tight sand source of construction sand cushion, lack of sand source, etc., and achieve extended construction period and construction period. The effect of shortening and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

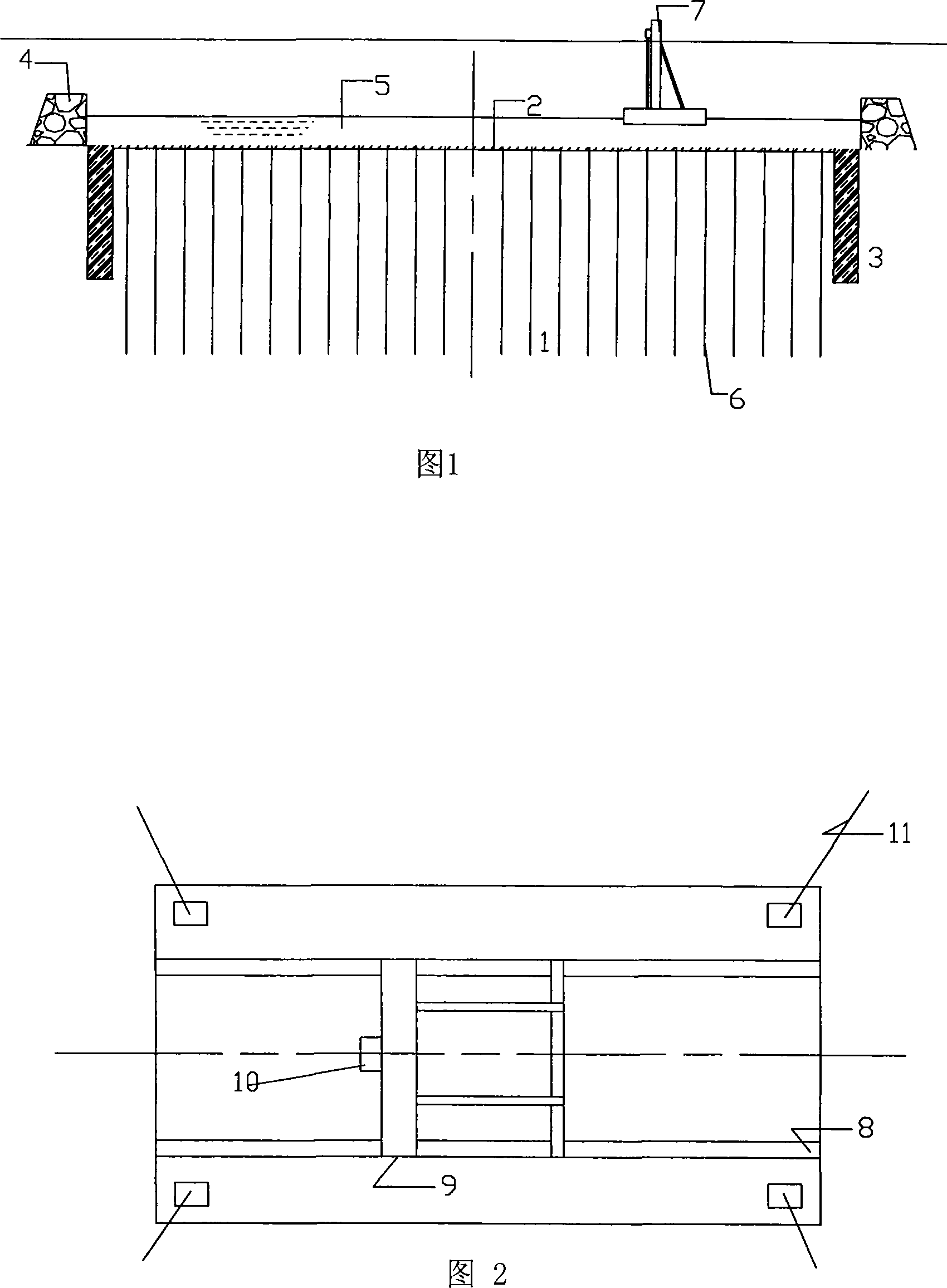

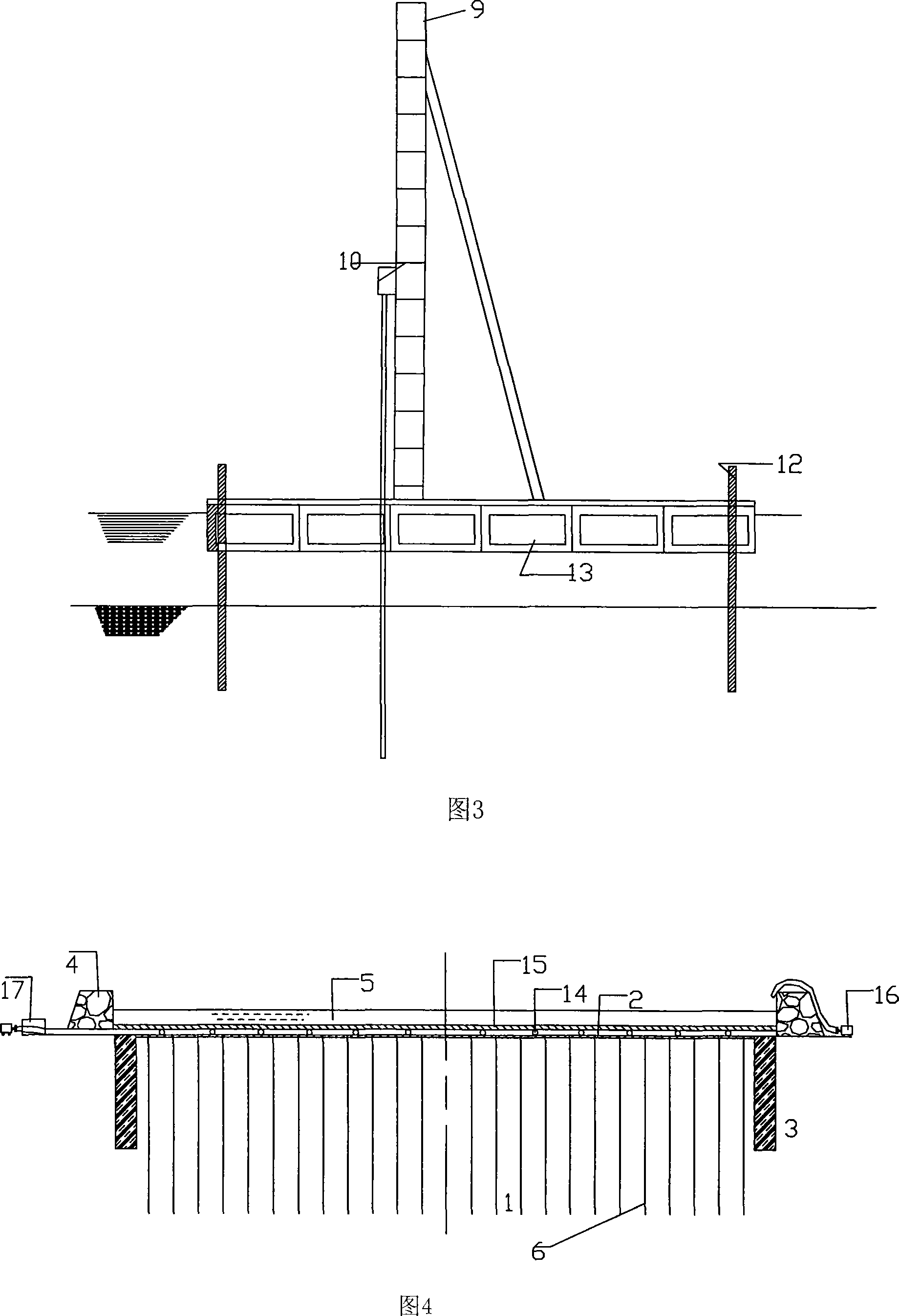

[0033] Example 1: The construction process of strengthening the soft soil foundation by vacuum preloading method

[0034] As shown in Figure 1 and Figure 4,

[0035] ① Firstly, the surface of the soft soil foundation 1 is cleaned up and the site is leveled;

[0036] ② Build a cofferdam 4 around the foundation 1;

[0037] ③ store water 5 in the cofferdam 4, and the water depth is 30-50cm;

[0038] ④Use floating inserter 7 to insert vertical drainage system, such as drainage board 6, bagged sand well, sand bag, etc.;

[0039] 5. after the drainage board 6 has been inserted, take away or bleed off the water storage 5, and embed a horizontal drainage system on the mud surface, such as laying PVC filter pipe 7, plastic blind ditch, sand bag (quilt), crushed water on the mud surface Stone bags, etc., and are connected with vertical drainage systems such as vertical drainage boards and bagged sand wells. When connecting, ensure that the joints of the horizontal and vertical draina...

Embodiment 2

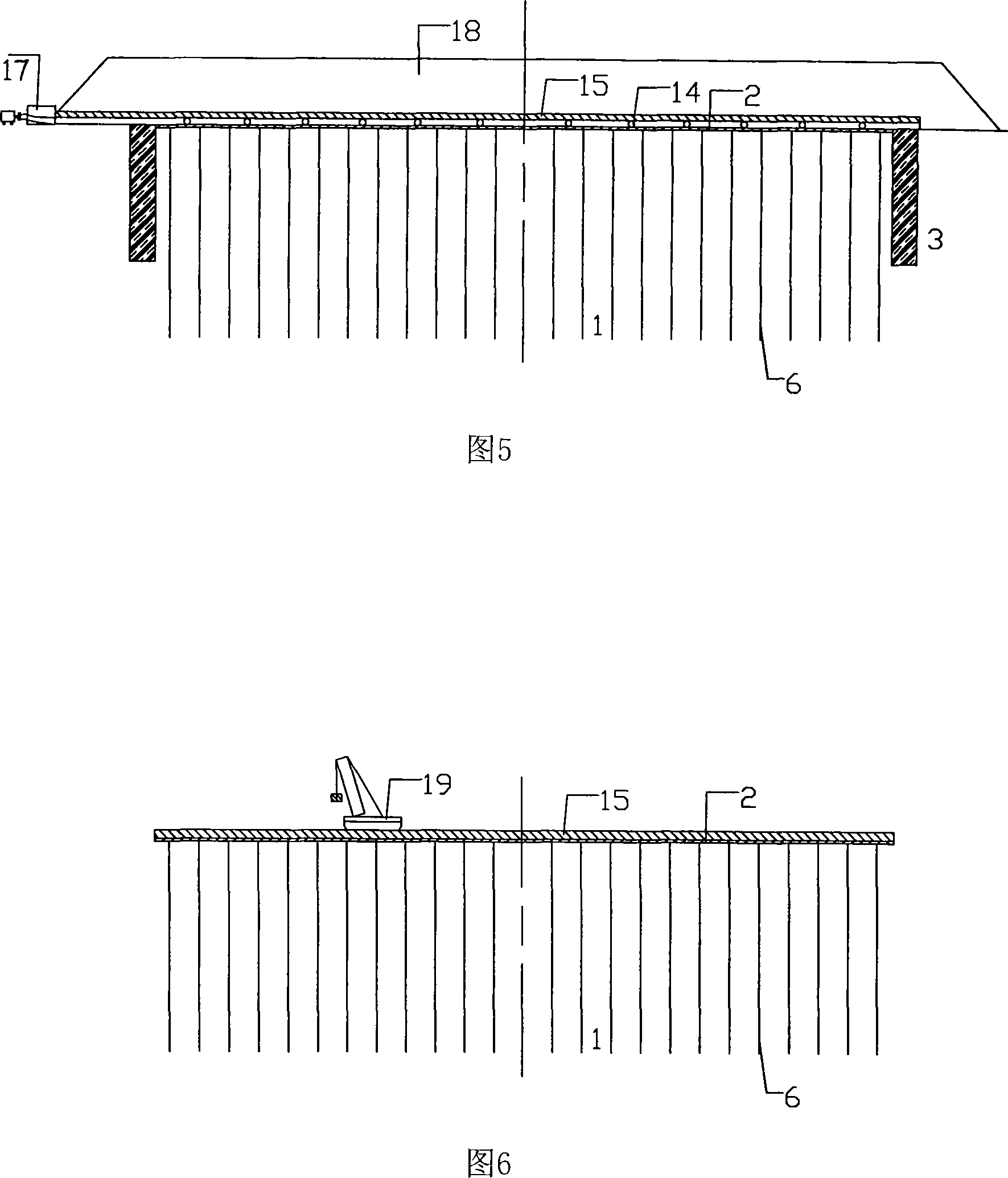

[0043] Embodiment 2: The construction process of strengthening the soft soil foundation by vacuum combined surcharge preloading method is shown in Figure 1 and Figure 5,

[0044] ① Cleaning and leveling the surface of the soft soil foundation 1;

[0045] ② Build a cofferdam 4 around the foundation 1;

[0046] ③ store water 5 in the cofferdam 4, and the water depth is 30-50cm;

[0047] ④Use floating inserter 7 to insert vertical drainage system, such as drainage board 6, bagged sand well, sand bag, etc.;

[0048] 5. after the drainage board 6 has been inserted, take away or bleed off the water storage 5, and embed a horizontal drainage system on the mud surface, such as laying PVC filter pipe 7, plastic blind ditch, sand bag (quilt), crushed water on the mud surface Stone bags, etc., and are connected with vertical drainage systems such as vertical drainage boards and bagged sand wells. When connecting, ensure that the joints of the horizontal and vertical drainage systems ar...

Embodiment 3

[0053] Example 3: The construction process of using vacuum preloading combined with dynamic compaction to strengthen soft soil foundation

[0054] As shown in Figure 1 and Figure 6,

[0055] ① Cleaning and leveling the surface of the soft soil foundation 1;

[0056] ② Build a cofferdam around the foundation 1;

[0057] ③ Store water in the cofferdam, the water depth is 30-50cm;

[0058] ④The vertical drainage system shall be installed by using the floating plug-in machine, such as drainage board 6, bagged sand wells, sand bags, etc.;

[0059]5. after the drainage plate 6 has been inserted, let off the water storage, and embed a horizontal drainage system on the mud surface, such as laying PVC filter pipes, plastic blind ditch, sand bags (quilt), gravel bags, etc. on the mud surface, and Connect with vertical drainage systems such as vertical drainage boards and bagged sand wells. When connecting, ensure that the joints of the horizontal and vertical drainage systems are wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com