X-ray detection robot for weld seam of storage tank

An X-ray and robot technology, applied in the field of non-destructive testing devices, can solve the problems of long detection cycle, heavy workload of patching and evaluation, and danger of operators, so as to improve detection efficiency and detection accuracy, and improve detection real-time performance and reliability, save the effect of mounting and developing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments and with reference to the drawings, so that those skilled in the art can implement it with reference to the text of the description.

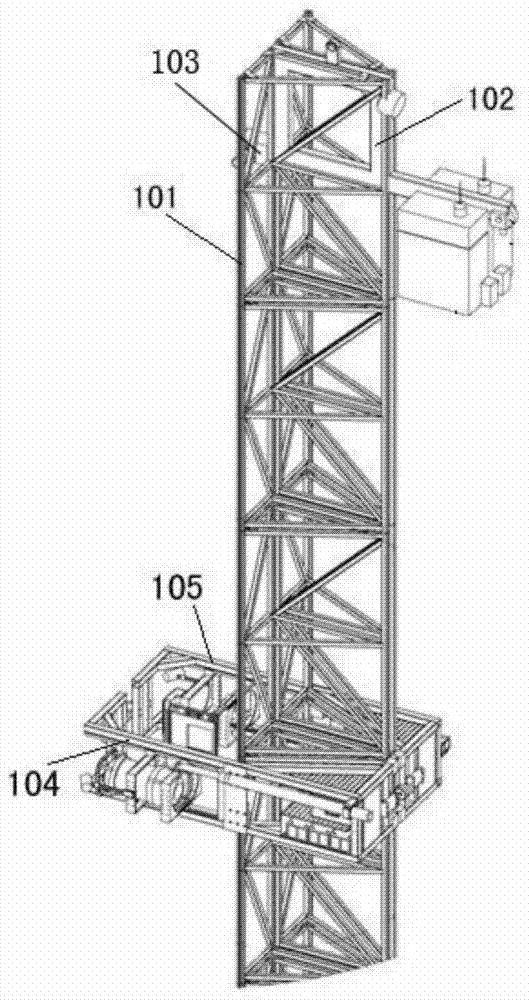

[0029] Such as figure 1 As shown, the X-ray inspection robot for the welding seam of the storage tank includes:

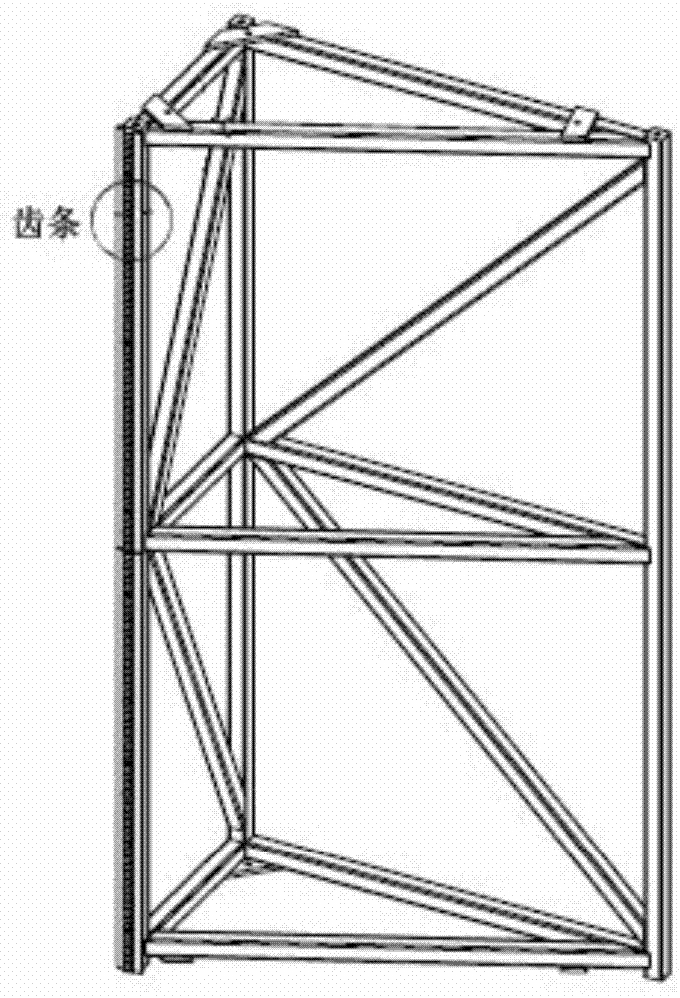

[0030] A straddle beam frame device 101 is composed of a first frame and a second frame symmetrically, and the upper ends of the first frame and the second frame are connected by a connecting device 102, the first frame There is a distance between the tank wall and the second stand. The first stand and the second stand are composed of a plurality of stand modules stacked vertically,

[0031] A beam transverse movement mechanism 103 is connected to the connecting device 102.

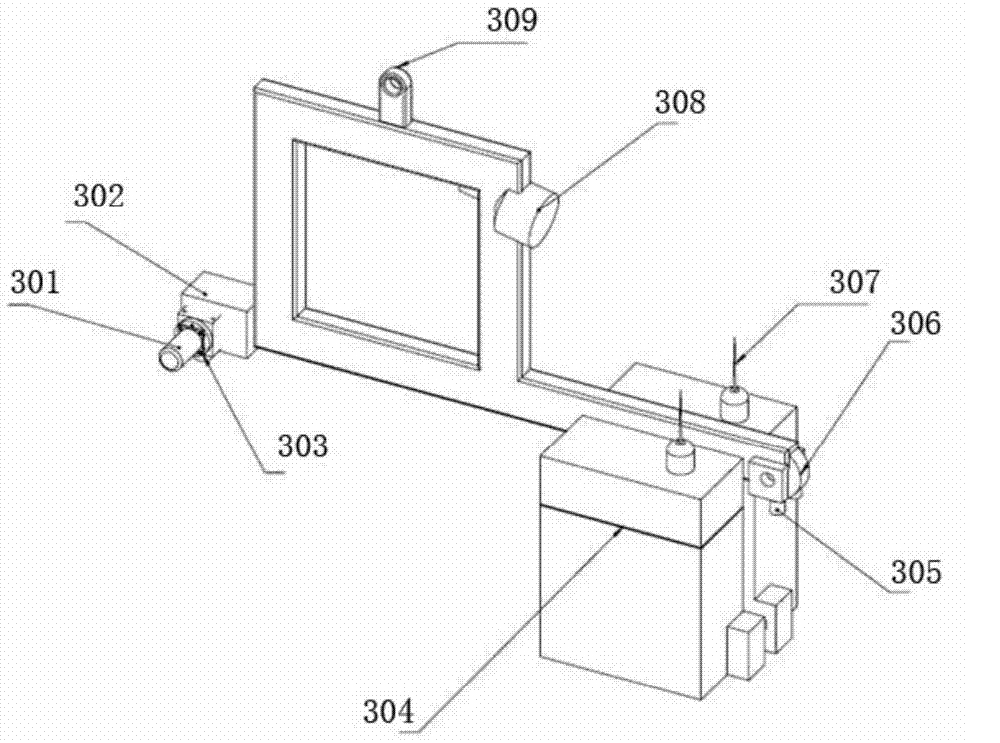

[0032] A longitudinal movement mechanism, an imaging system lateral movement mechanism, an X-ray generator base, and an X-ray transmitter of the X-ray imagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com