Method for calibrating micro thrust

A calibration method and thrust technology, which is applied in the measurement of elastic deformation force by measuring gauges, etc., can solve problems such as the problem of affecting the accurate measurement of micro thrust calibration, and achieve the effect of simple control and use and easy to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

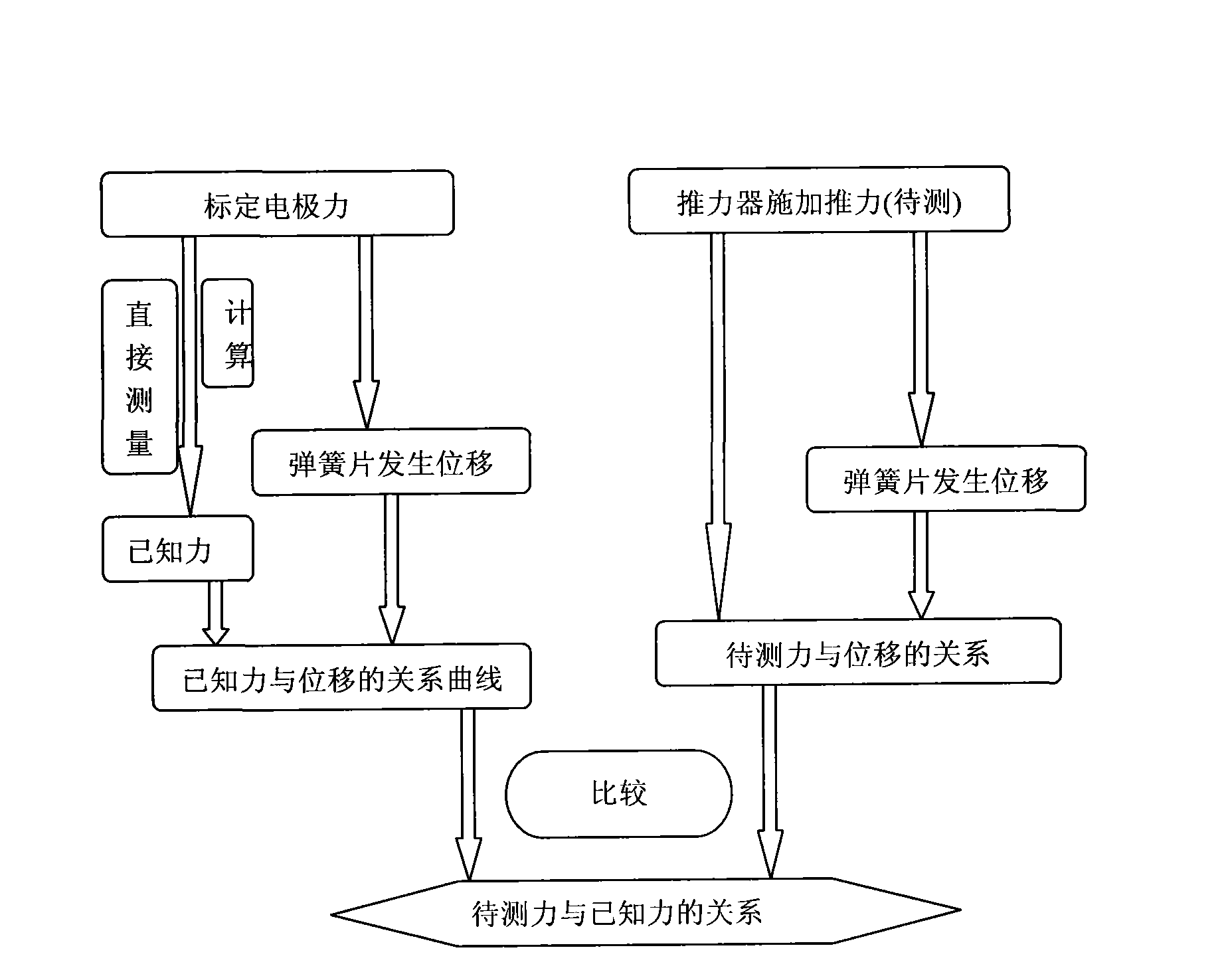

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

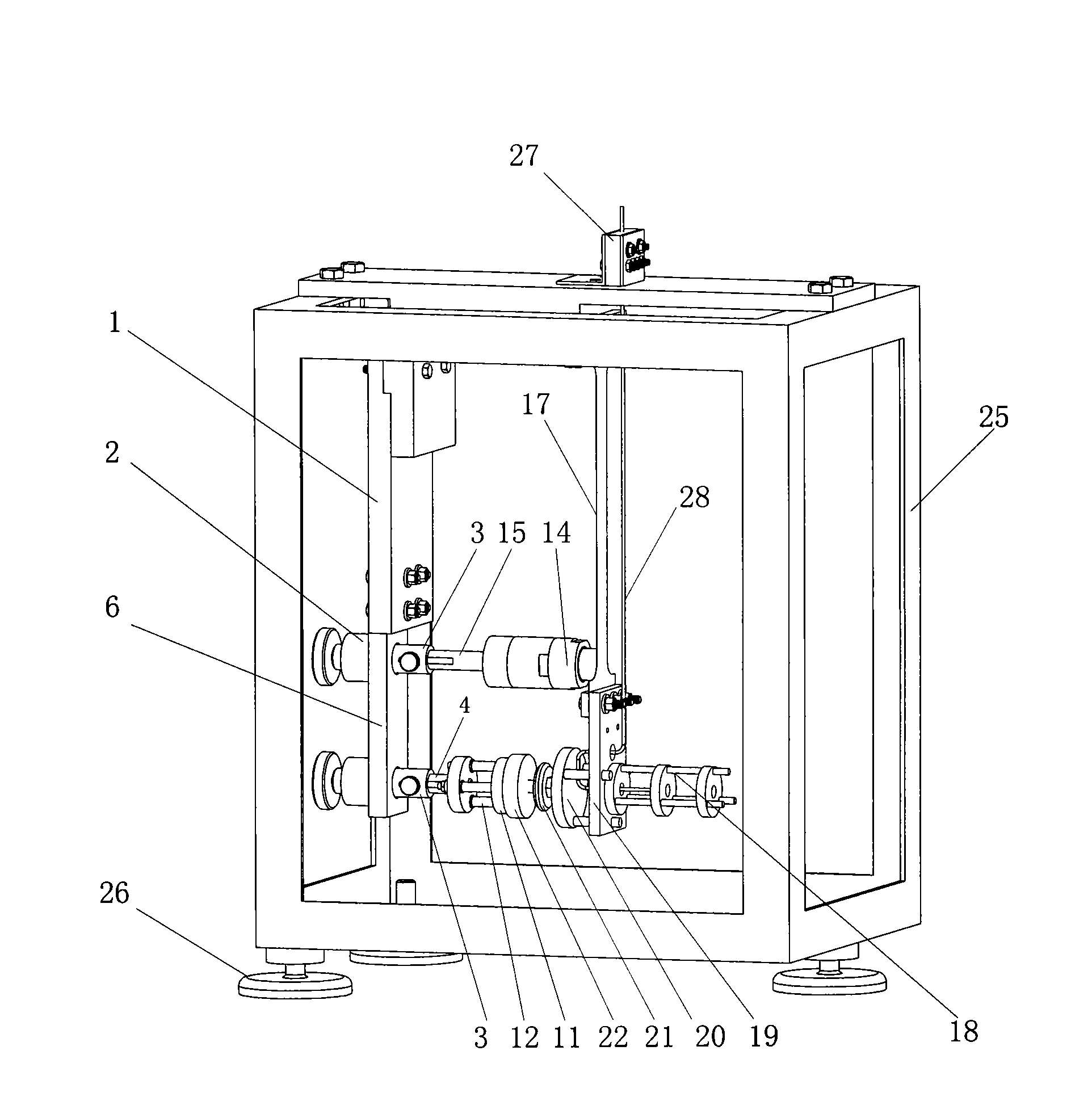

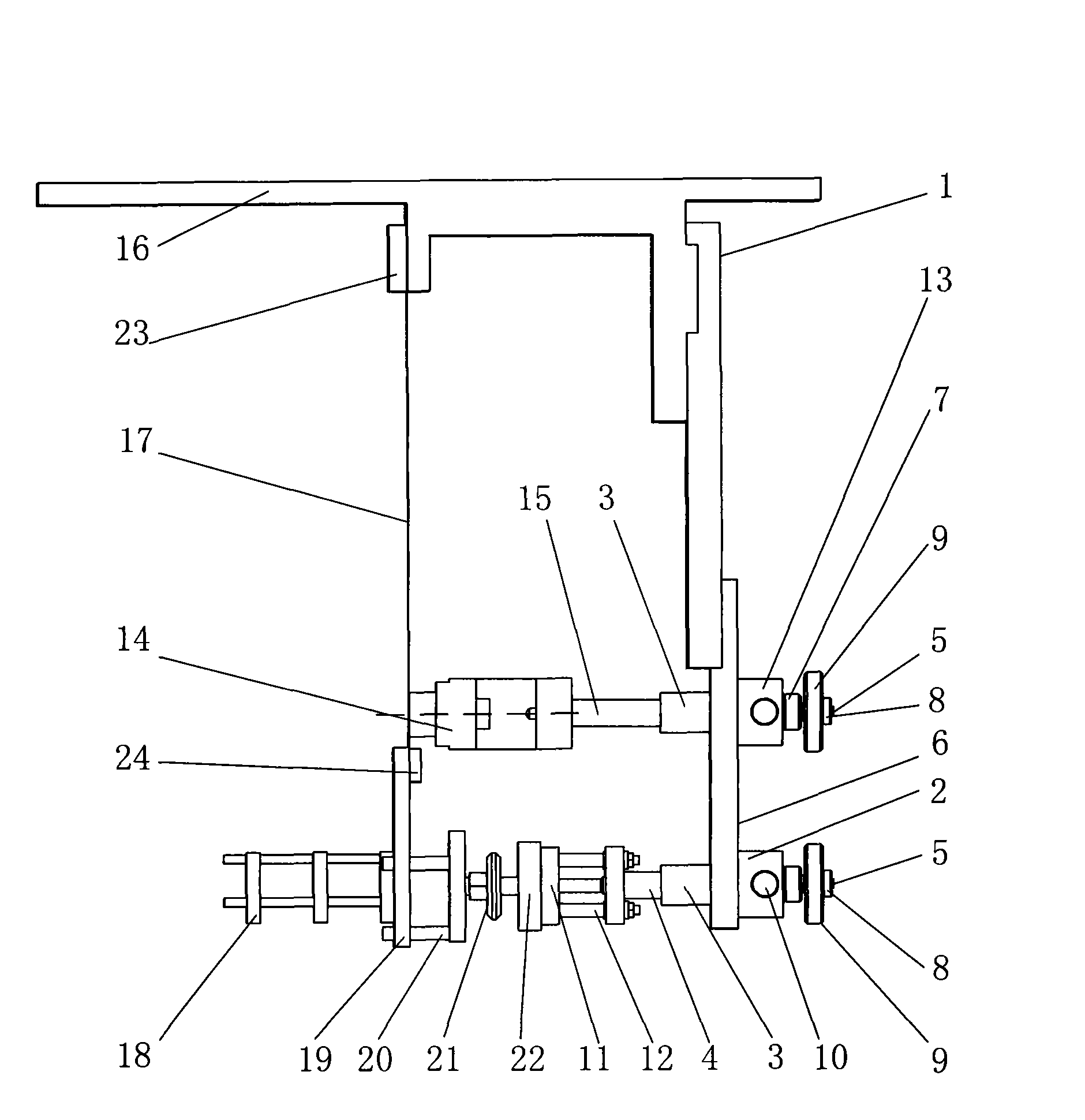

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] Such as figure 2 , 3 As shown, the hardware device applied by the method of the present invention is installed:

[0044] (1), first install the adjustment bracket 26 on the thrust frame frame 25, then install the main beam 16 on the thrust frame frame 25, then install the lateral movement seat 1 on the main beam 16, and then fix the longitudinal movement seat 6 On the lateral moving seat 1 , the electrode seat 2 and the sensor seat 13 are welded on the longitudinal moving seat 6 .

[0045] (2) Assemble the fixed shaft 3, the adjusting screw rod 5, the washer end cover 7, the lock nut 8, the handle 9, and the moving long shaft 15 into one, and then fix it on the sensor seat 13 with the fixing screw 10.

[0046] (3) Assemble the fixed shaft 3 moving shaft 4 adjusting screw rod 5 washer end cover 7 locking nut 8 handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com