Testing stand of friction torque of automotive wheel hub bearing

A technology of friction torque and automobile wheel hub, which is applied in the field of testing, can solve the problems that it is difficult to meet the actual needs of hub bearing manufacturers and users, the increase of bending moment, and the failure to realize the criticality of friction torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description will be made below in conjunction with the accompanying drawings.

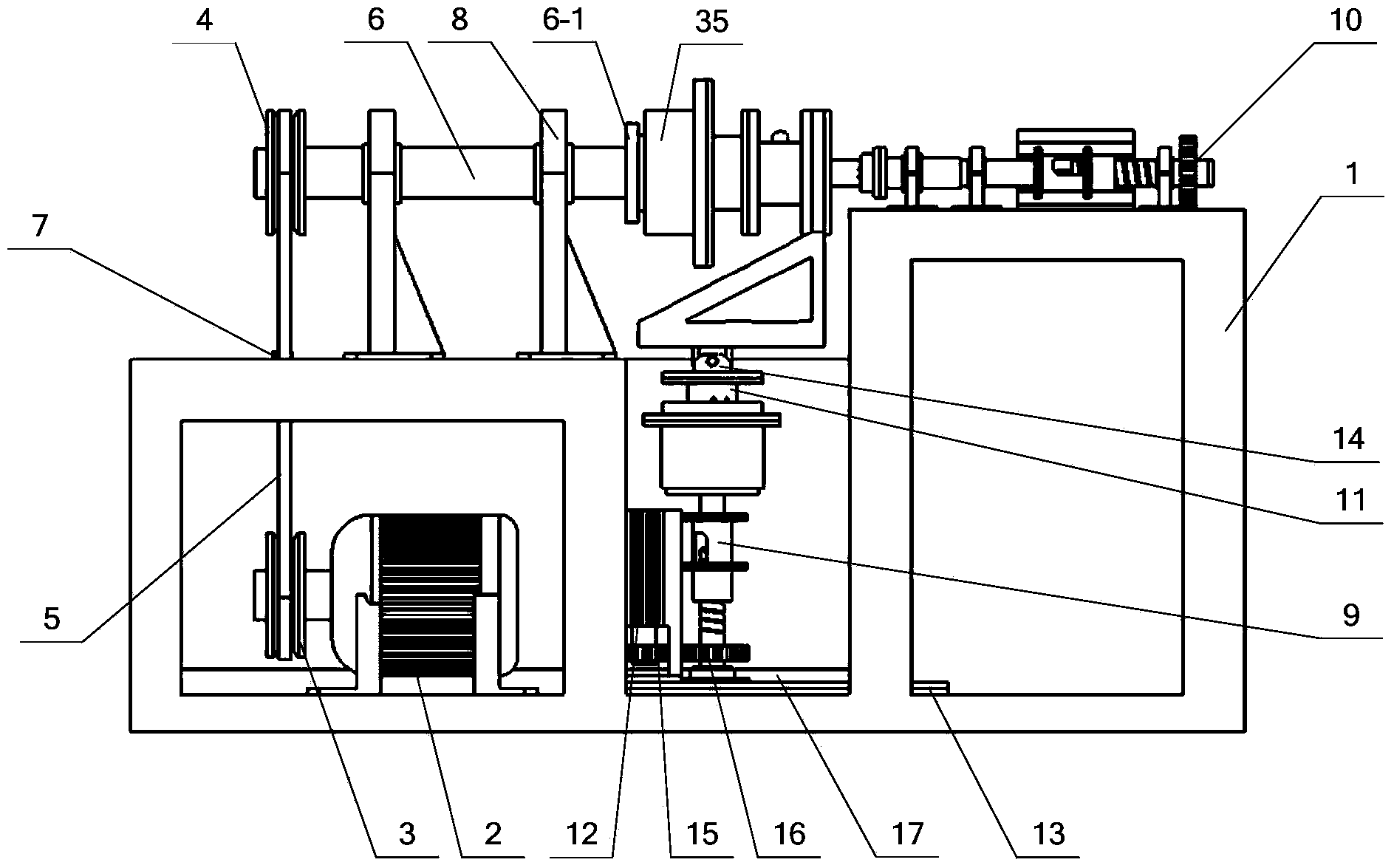

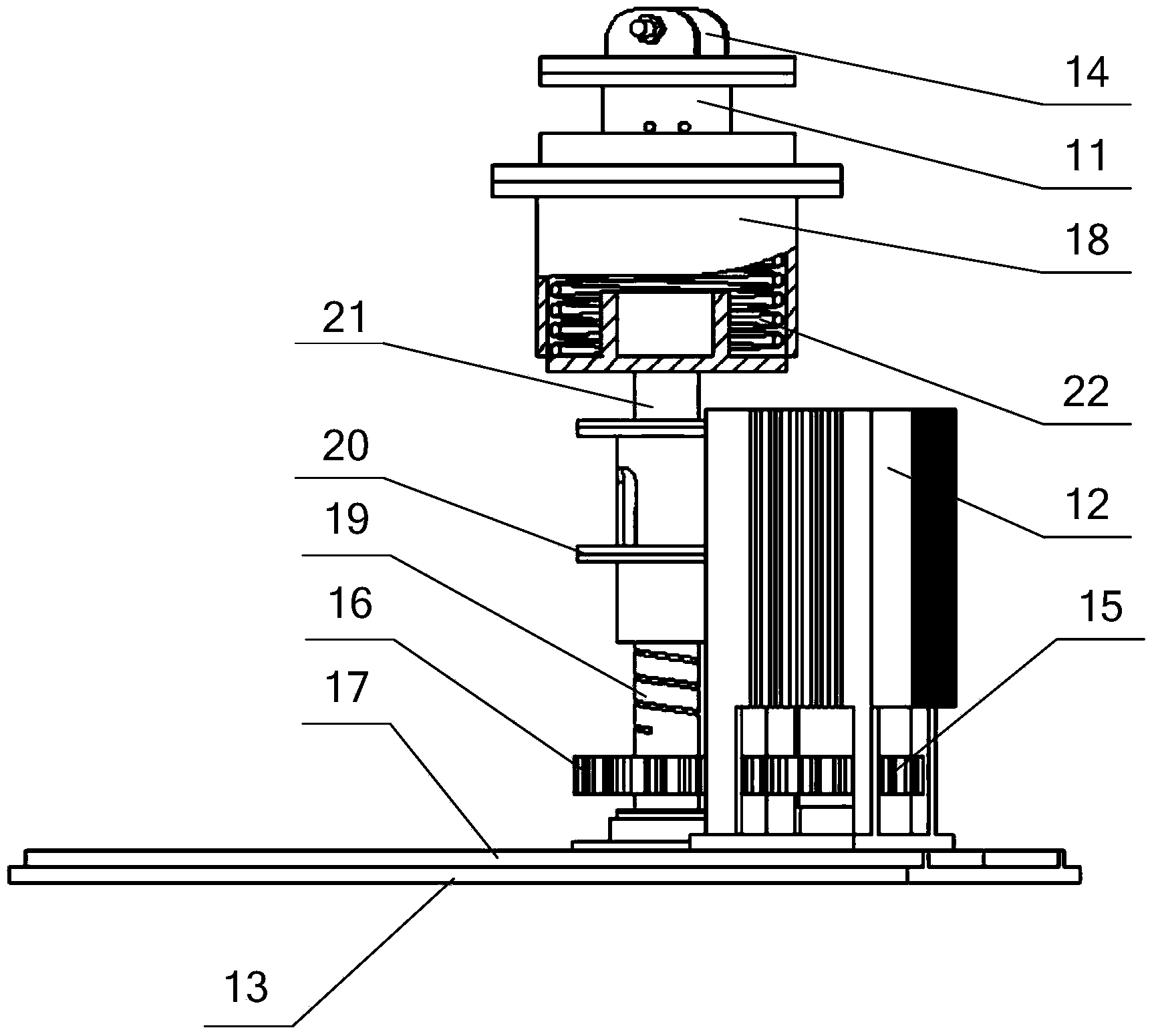

[0019] Such as figure 1 As shown, an automobile hub bearing friction torque test bench includes a test bench frame 1, a driving mechanism, a main shaft 6, a tensioning device 7, a radial loading mechanism 9, an axial loading mechanism 10 and a bearing fixing device under test.

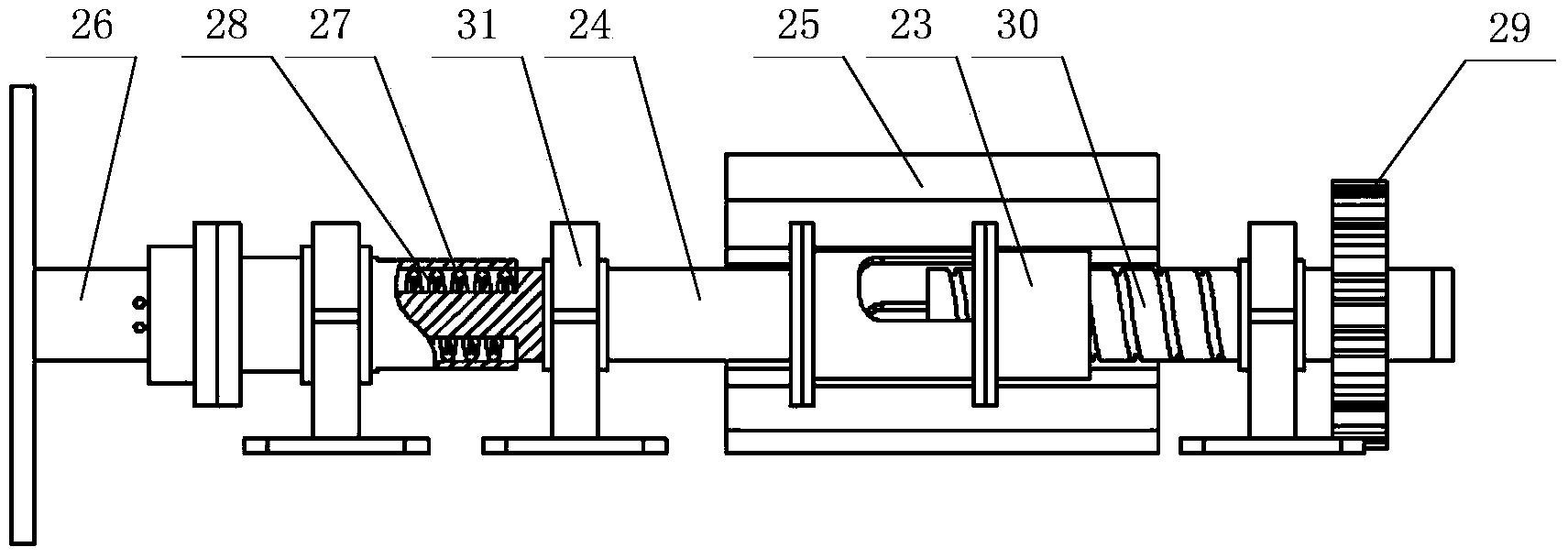

[0020] The driving mechanism includes a driving motor 2, a driving pulley 3, a driven pulley 4 and a belt 5; the output shaft of the driving motor 2 is fixed to the driving pulley 3, the driving pulley 3 is connected to the driven pulley 4 through the belt 5, and the driven pulley 4 is fixed on On the main shaft 6; the tensioning pulley of the tensioning device 7 tensions the belt 5; the main shaft 6 is supported on the two main shaft supporting seats 8 through two bearings; the main shaft 6 is provided with a shaft shoulder 6-1, and the head of the main shaft 6 is provided with Splines; two spindle support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com