Inclination angle adjustable rocket engine ground test stand frame

A rocket engine and engine support technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of damage and danger of the oxidant storage tank, and achieve the effect of ensuring the launch attitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

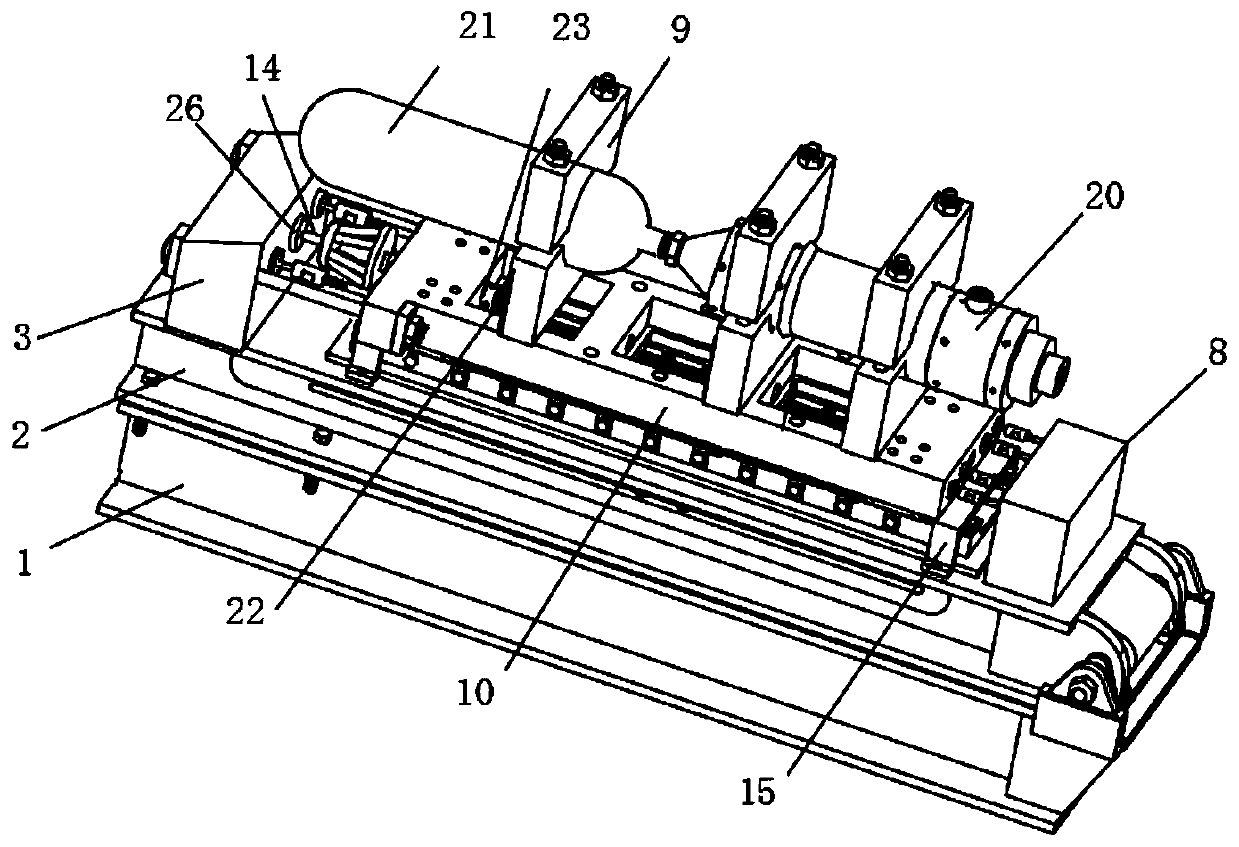

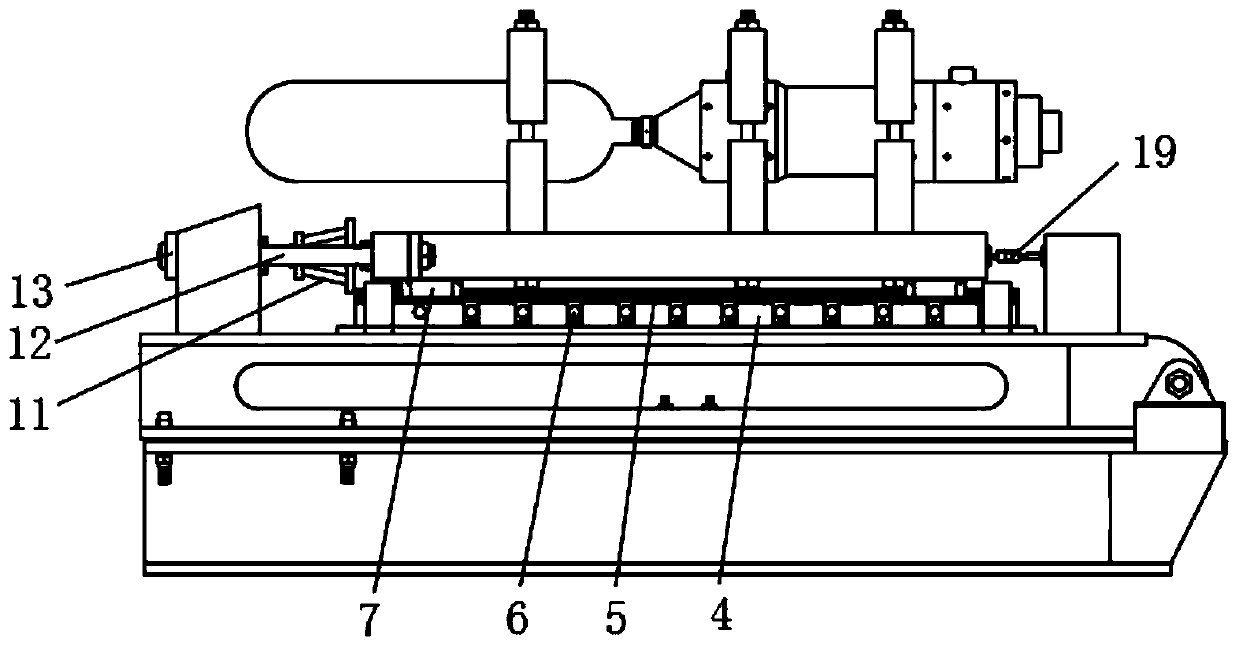

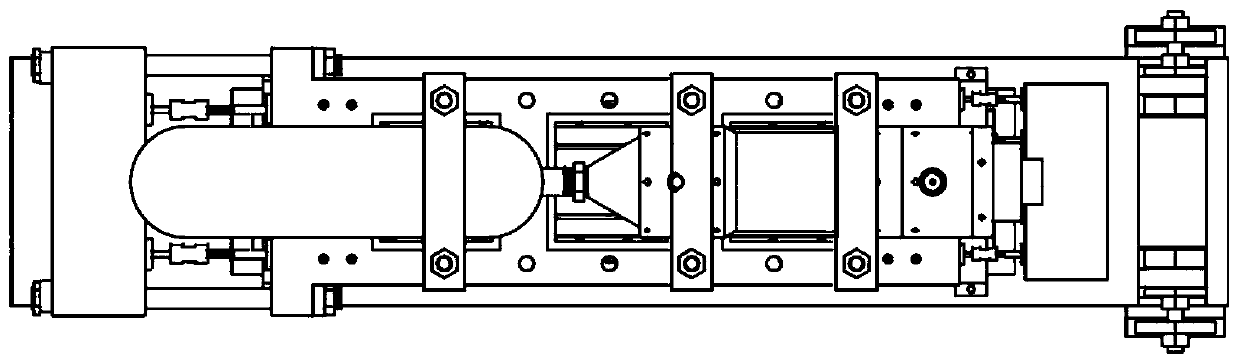

Embodiment 1

[0063] Horizontal thrust testing of solid rocket motors. Fix the guide rail 5 on the guide rail fixing platform 4 with hexagonal bolts, lock the bolts with the specified torque, and fix the guide rail lateral fixing plate 6 on the guide rail fixing platform 4 with hexagonal screws to limit the tangential direction of the guide rail 5 during the test. To move, use screws to connect and fix the moving frame 10 with the rolling slider 7. The engine bracket 9 is assembled on the moving frame 10, the position is adjusted to suit the size of the experimental engine 20 and fixed with the experimental engine 20 by bolts. The limit frame 15 is fixed on the moving frame 10 by bolts, and the position is adjusted before fixing so that the rolling slider 7 can only move along the thrust direction of the engine. At the same time, a support rod 19 is set between the bearing pier 3 and the movable frame 10 to prevent the movable frame 10 from moving and colliding with the thrust sensor 26 . ...

Embodiment 2

[0066] Vertical thrust test of solid-liquid hybrid rocket motor. Fix the guide rail 5 on the guide rail fixing platform 4 with hexagonal bolts, lock the bolts with the specified torque, and fix the guide rail lateral fixing plate 6 on the guide rail fixing platform 4 with hexagonal screws to limit the tangential direction of the guide rail 5 during the test. To move, use screws to connect and fix the moving frame 10 with the rolling slider 7. The oxidant storage tank 21 is connected with the experimental engine 20 by thread fit, so that the experimental engine 20 and the oxidant storage tank 21 form a solid whole. The engine bracket 9 is installed on the moving frame 10, and the adjusted position is adapted to the overall size of the engine and fixed by bolts. The limit frame 15 is fixed on the moving frame 10 by bolts. The support rod 19 is fixed on the support rod fixing seat 8 by bolts, and the height of the support rod 19 is adjusted so that the plane of the support rod ...

Embodiment 3

[0069] Inclined thrust testing of solid rocket motors. Fix the guide rail 5 on the guide rail fixing platform 4 with hexagonal bolts, lock the bolts with the specified torque, and fix the guide rail lateral fixing plate 6 on the guide rail fixing platform 4 with hexagonal screws to limit the tangential direction of the guide rail 5 during the test. To move, use screws to connect and fix the moving frame 10 with the rolling slider 7. The engine bracket 9 is installed on the moving frame 10, and the adjusted position is adapted to the overall size of the engine and fixed by bolts. The limit frame 15 is fixed on the moving frame 10 by bolts. The support rod 19 is fixed on the support rod fixing seat 8 by bolts, and the height of the support rod 19 is adjusted so that the plane of the support rod 19 is in contact with the plane of the moving frame 10 . At the same time, a support rod 19 is set between the bearing pier 3 and the movable frame 10 to prevent the movable frame 10 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com