Integrated device for deodorization and sewage treatment in municipal sewage plant and technology thereof

A municipal sewage and sewage treatment technology, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc., can solve the problem of high land quality and environmental requirements, and the treatment of odor concentration should not be too high , low maintenance and management costs, etc., to achieve the effect of low construction and operation costs, small construction volume, and reduced construction and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

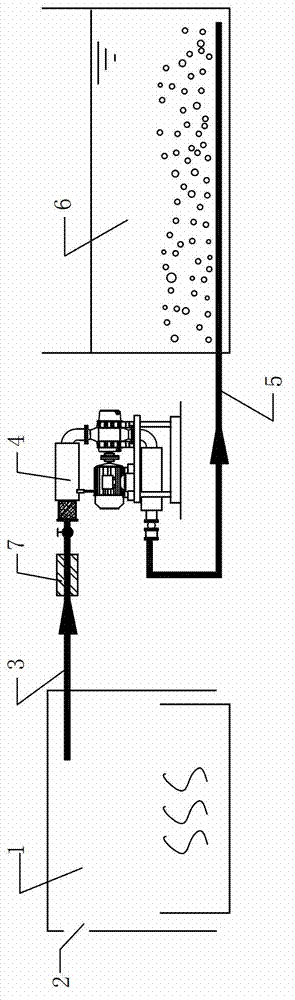

Image

Examples

Embodiment 1

[0033] A certain original municipal sewage treatment plant has been designed and modified, and the patent of the invention is used to achieve the functions of aeration and pumping to treat malodorous gas at the same time. The daily water treatment capacity of the sewage treatment plant is 50,000 d / t, the COD is about 300mg / L, the BOD is about 180mg / L, and the ammonia nitrogen is about 25 mg / L. The system uses UNITANK technology. The system collects the main sources of gas from the grille, aeration grit chamber and sludge dewatering machine room. The aeration grit chamber adopts a full-coverage form, and the total gas treatment capacity is about 8000m 3 / h (including ventilation volume). The designed aeration volume of the original sewage treatment plant is 9200 m 3 / h, the air volume is 162.62 m 3 There are 2 Roots blowers per min (one for use and one for standby), and the aeration equipment adopts the diaphragm microporous aeration method. In this reconstruction project, ...

Embodiment 2

[0036] Design, renovation and construction of an existing municipal sewage treatment plant. The sewage treatment plant has a water treatment capacity of 80,000 tons per day, and is designed to treat COD at 320mg / L, BOD at about 200mg / L, and ammonia nitrogen at about 30 mg / L. Adopt biological contact oxidation process to collect and treat the malodorous gas from the grid and aeration grit chamber, the total gas volume is about 13000m 3 / h (including ventilation volume). The design aeration volume of the sewage treatment plant is 16500 m 3 / h, the air volume is 143.26 m 3 There are 3 units per min (two-purpose and one standby), and the aeration equipment adopts hydraulic shear aerators. In this reconstruction project, the original blower and aeration equipment are used, and only the odor equipment collection device and conveying device are added, and the closed odor source is connected to the air inlet of the blower through pipelines. Considering that the amount of malodorou...

Embodiment 3

[0039] Design and construction of a new municipal sewage treatment plant. The sewage treatment plant has a water treatment capacity of 100,000 tons per day, and is designed to treat COD at 350mg / L, BOD at about 200mg / L, and ammonia nitrogen at 30 mg / L. The A / A / O process is used to collect and process the malodorous gas from the grille, pool A, and sludge dewatering machine room, with a total gas volume of about 17,500m 3 / h (including ventilation volume). The design aeration volume of the sewage treatment plant is 23000 m 3 / h, the air volume is 192.04 m 3 There are 3 units per min (two-purpose and one standby), and the aeration equipment adopts underwater air diffuser aeration. This system also adopts the operation mode of normally open in summer and regularly open in winter. After the construction trial operation is stable, the long-term operation data shows that the COD of the secondary effluent (average data) of the sewage treatment plant is 30-60mg / L, the ammonia nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com