Lithium titanate/M-graphene composite cathode material for lithium ion battery and preparation method of lithium titanate/M-graphene composite cathode material

A graphene composite, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor high-rate charge and discharge performance, low specific capacity, poor conductivity, etc., to achieve good rate performance, high ratio Capacity, the effect of improving poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

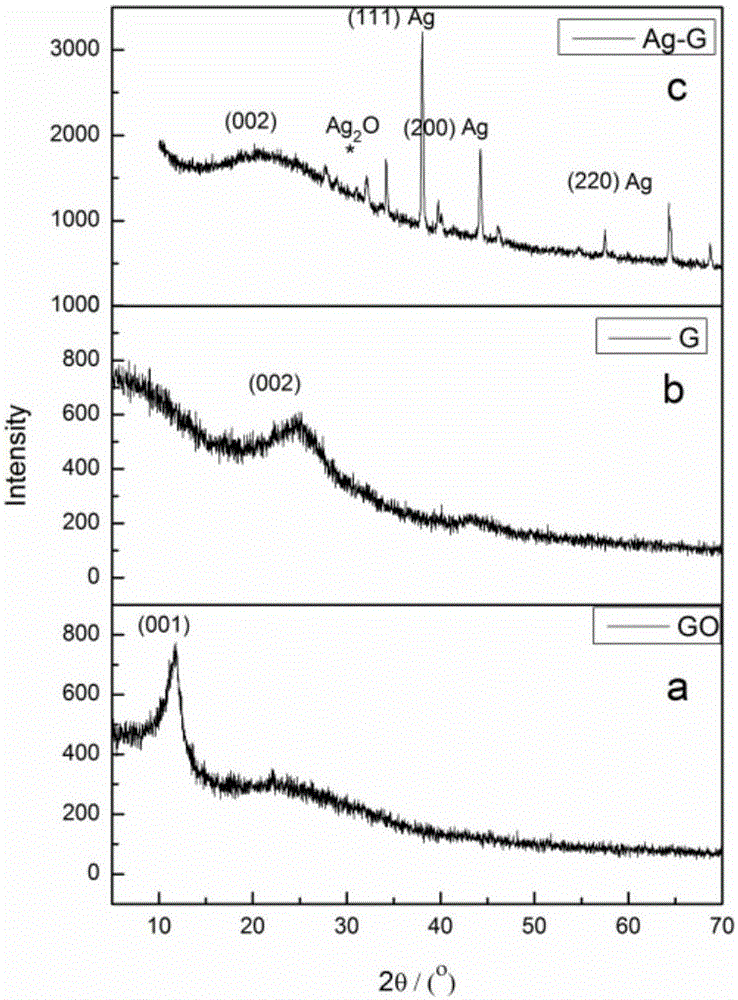

[0047] Graphite oxide, graphene and silver-graphene are prepared according to the following steps in this example:

[0048] a. Put 3g of graphite powder and 18g of potassium permanganate into a flask for mixing, then add a mixed acid obtained by mixing 360mL of concentrated sulfuric acid and 40mL of concentrated phosphoric acid into the flask, mix well and place on a magnetic stirrer Heating while stirring, continuous reaction at 50°C for 12 hours to fully oxidize the graphite powder; after the reaction is completed, pour the mixed solution into pre-frozen ice water (the ice cube is made of about 400ml water and 8-10ml Hydrogen peroxide solution with a mass fraction of 30%), let it stand for a period of time until the ice cubes completely melt; then, wash them with deionized water, 0.1mol / L dilute hydrochloric acid, and absolute ethanol, and dry to obtain graphite oxide .

[0049] b. Put 0.06g of synthesized graphite oxide into 30mL of absolute ethanol, perform ultrasonic tre...

Embodiment 2

[0052] Lithium titanate / silver-graphene composite negative electrode material for lithium ion battery is prepared according to the following steps in this example:

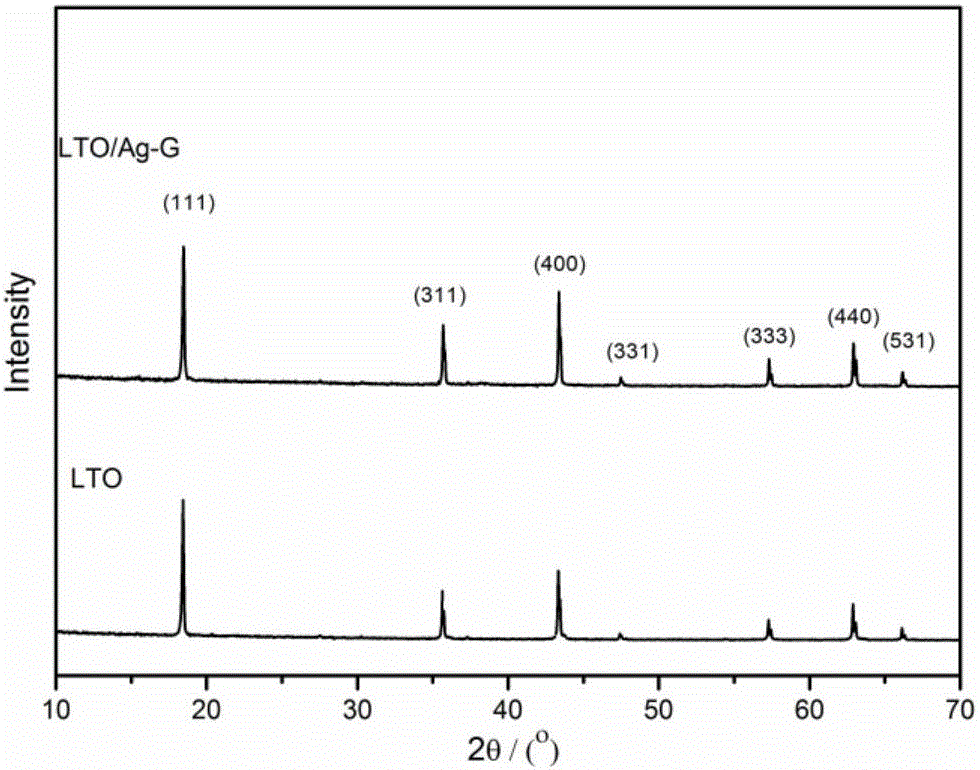

[0053] a. Weigh 0.043mol of LiOH.H 2 O was dissolved in deionized water to form lithium hydroxide solution A with a concentration of 2mol / L, and 0.05mol of Ti (OC 4 h 9 ) 4 Pour into absolute ethanol, the volume ratio of the two is 1:1, put it on a magnetic stirrer and stir quickly to form solution B; slowly add the prepared solution A into solution B, and then continue to stir for 1-2h ;Transfer the resulting white emulsion to a polytetrafluoroethylene reactor, after continuous reaction at 180°C for 24h, centrifugally wash with deionized water or absolute ethanol, and then dry at 60°C to obtain a precursor . Finally, calcined at 700 °C for 8 hours to obtain white Li 4 Ti 5 o 12 particles

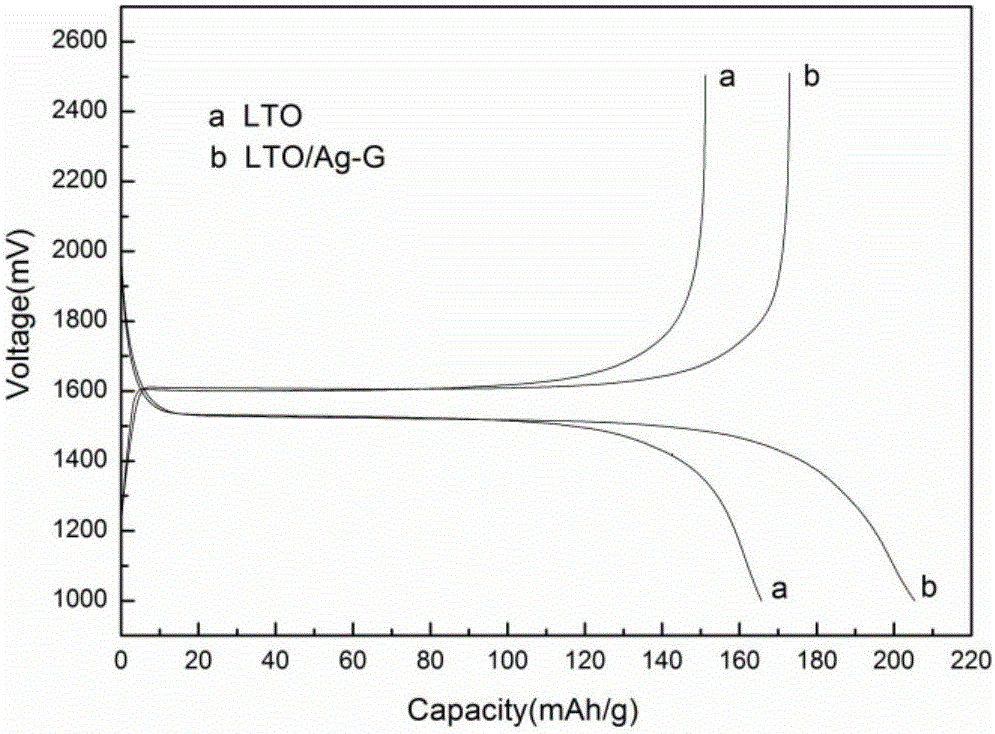

[0054] b. First, take 2g of the white LTO that has been synthesized above and put it into 20mL of absolute ethanol, s...

Embodiment 3

[0059] Lithium titanate / silver-graphene composite negative electrode material for lithium ion battery is prepared according to the following steps in this example:

[0060] A, adopt the same method as embodiment 2 to prepare pure phase lithium titanate;

[0061] b. First, take 2g of the white LTO that has been synthesized above and put it into 20mL of absolute ethanol, stir quickly to disperse the material evenly, and then put the prepared 2.0g / L GO (first ultrasonic treatment for one hour to make the oxidation Graphite flake separation), silver nitrate solution and hydrazine hydrate were slowly added dropwise to the above solution, GO and AgNO 3 The amount added is 3% of the weight of LTO, and hydrazine hydrate is AgNO according to the molar ratio of substances. 3 : Hydrazine hydrate = 1:2 is added, then the uniformly dispersed solution is transferred to a polytetrafluoroethylene reactor, reacted continuously at 120°C for 16 hours, after the temperature is naturally cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com