Lithium titanate/graphene composite cathode material for lithium ion battery

A graphene composite, lithium-ion battery technology, applied in battery electrodes, batteries, negative electrodes and other directions, can solve the problems of low conductivity, poor high-rate charge and discharge performance, low specific capacity of lithium titanate negative electrode materials, etc. The effect of specific capacity, improved rate performance, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

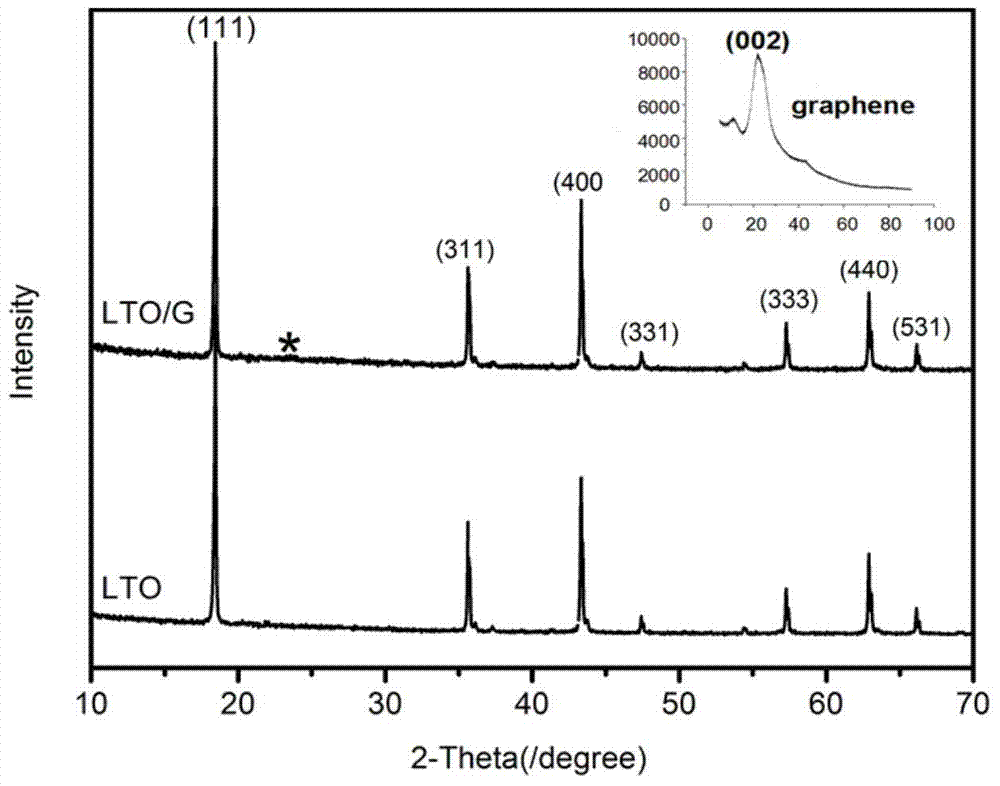

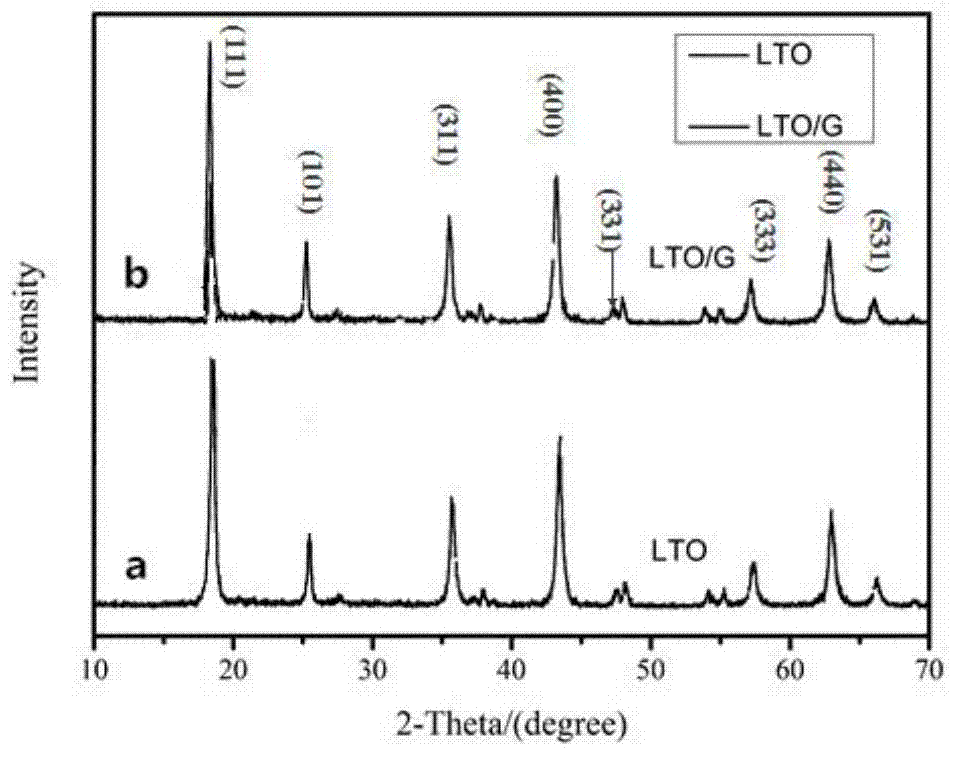

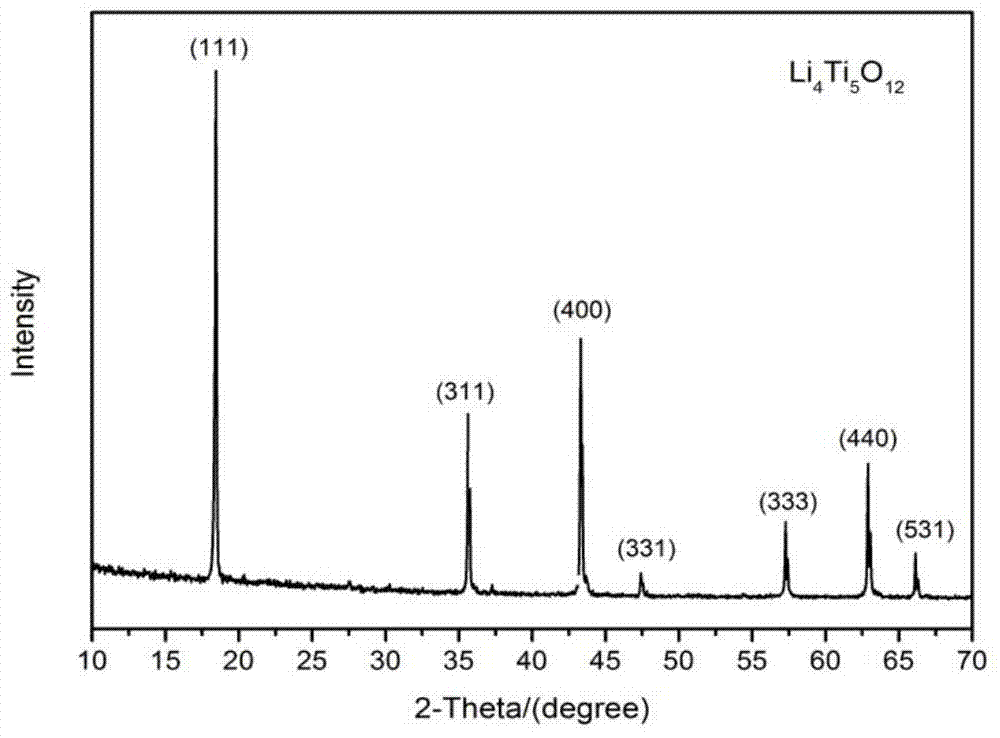

[0058] Lithium titanate / graphene composite negative electrode material for lithium ion battery is prepared according to the following steps in this example:

[0059] a. Weigh 0.04mol of lithium hydroxide (LiOH·H 2 O) 1.680g, dissolved in 20ml of deionized water to prepare a 2mol / L lithium hydroxide solution; use a graduated cylinder to measure 17ml of 0.05mol butyl titanate solution, mix it with an equal volume of absolute ethanol, and stir under magnetic force Add the prepared lithium hydroxide solution drop by drop to obtain a white suspension, continue to stir for 1 hour, then transfer it to the reaction kettle for 24 hours at 180°C, cool to room temperature, and place it in a muffler after centrifugation, washing, and drying. Calcined in a furnace at 500°C for 10 hours, the obtained white powder is lithium titanate, which is ground for later use.

[0060] b, the above prepared lithium titanate Li 4 Ti 5 o 12 Weigh 2g, dissolve it in 20ml of absolute ethanol and stir it...

Embodiment 2

[0064] Lithium titanate / graphene composite negative electrode material for lithium ion battery is prepared according to the following steps in this example:

[0065] a. Weigh 0.043mol of lithium hydroxide (LiOH·H 2 O) 1.815g, wherein in order to make up for the loss of lithium at high temperature, make lithium hydroxide excess 8%, dissolve in 10ml deionized water, and prepare 4mol / L lithium hydroxide solution; measure 0.05mol titanic acid with a graduated cylinder Mix 17ml of butyl ester solution with an equal volume of absolute ethanol; add the prepared lithium hydroxide solution dropwise under magnetic stirring to obtain a white suspension, continue to stir for 1 hour, and then transfer to the reaction kettle for reaction at 180°C 24 hours; cool to room temperature, centrifuge, wash, and dry, then place in a muffle furnace for calcination at 700°C for 10 hours, and the white powder obtained is lithium titanate, which is ground for later use.

[0066] b, the above prepared l...

Embodiment 3

[0070] Lithium titanate / graphene composite negative electrode material for lithium ion battery is prepared according to the following steps in this example:

[0071] a. Weigh 0.043mol of lithium hydroxide (LiOH·H 2 O) 1.815g, wherein in order to make up for the loss of lithium at high temperature, make lithium hydroxide excess 8%, dissolve in 20ml deionized water, and prepare 2mol / L lithium hydroxide solution; measure 0.05mol titanic acid with a graduated cylinder Mix 17ml of butyl ester solution with an equal volume of absolute ethanol, add the prepared lithium hydroxide solution drop by drop under magnetic stirring, and continue stirring for 1 hour after obtaining a white suspension, then transfer it to a reaction kettle for reaction at 180°C 24 hours; cool to room temperature, centrifuge, wash, and dry, then place in a muffle furnace for calcination at 700°C for 10 hours, and the white powder obtained is lithium titanate, which is ground for later use.

[0072] b, the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com