Electrical filter board and application of same in highly concentrated organic wastewater

An electric filter plate and filter plate technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high labor intensity, easy packing, and short service life for replacing fillers. , to achieve the effect of improving the biodegradability of wastewater, reducing the content of organic matter, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

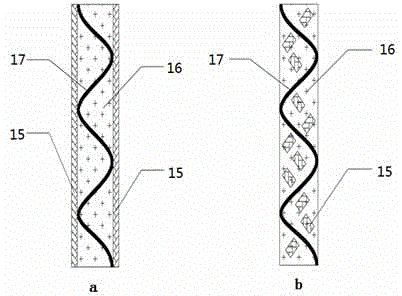

Embodiment 1

[0034] Embodiment 1: The electric filter plate is a cathode filter plate and an anode filter plate. The cathode electric filter plate includes cathode electrocatalytic materials, micro-electrolytic materials and conductor materials, and the anode electric filter plate includes anode electrocatalytic materials, micro-electrolytic materials and conductor materials. , wherein the cathode electrocatalytic material is titanium, the anode electrocatalytic material is a titanium-nickel alloy plate, and the structure is a porous plate, the hole diameter of the porous plate is 30 mesh; the thickness of the electric filter plate is 10 mm, and the electrocatalytic material is pressed into a plate The shape is distributed on both sides of the micro-electrolytic material; the micro-electrolytic material is made of aluminum-carbon mixed according to the volume ratio of 0.8:1, and its shape is a spherical particle with a particle size range of 18 mesh. Copper shavings (18 mesh in particle siz...

Embodiment 2

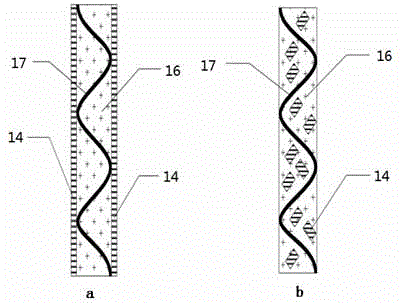

[0039] Embodiment 2: The electric filter plate is a cathode filter plate and an anode filter plate, the cathode electric filter plate includes cathode electrocatalytic materials, micro-electrolytic materials and conductor materials, and the anode electric filter plate includes anode electrocatalytic materials, micro-electrolytic materials and conductor materials , where the cathode electrocatalytic material is stainless steel, the anode electrocatalytic material is titanium-manganese alloy, and the electrocatalytic material is particles broken from porous plates (the particle length is 5-15mm and the width is 3-6mm); the thickness of the electric filter plate The electrocatalytic material is dispersed and mixed in the micro-electrolytic material with a mass ratio of 1:1, and then pressed into a plate shape; the micro-electrolytic material is made of iron-carbon mixed with a volume ratio of 1:1, and its shape is Porous columnar shape with a particle size of 60 mesh. Platinum sh...

Embodiment 3

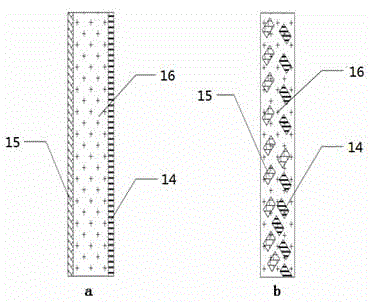

[0044] Embodiment 3: The electric filter plate is a cathode filter plate and an anode filter plate, the cathode electric filter plate includes cathode electrocatalytic material, micro-electrolytic material and conductor material, and the anode electric filter plate includes anode electrocatalytic material, micro-electrolytic material and conductor material , wherein the cathode electrocatalytic material is graphite, the anode electrocatalytic material is titanium-magnesium alloy, and the electrocatalytic materials are all in the shape of a porous plate (pore size 100 mesh); the thickness of the electric filter plate is 30 mm, and the electrocatalytic material is pressed into a plate shape and distributed in the micro-electrolytic material on both sides. The micro-electrolytic material is made of aluminum-carbon mixed according to the volume ratio of 1.2:1. Its shape is amorphous particles with a particle size of 100 mesh. Add copper filings with a volume ratio of 0.3% (particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com