Cement grinding aid and preparing method thereof

A cement grinding aid and lignin technology, applied in the field of cement additives and its preparation, can solve the problems of high alkali content, layered settlement, excessive chloride ion content, etc., achieve good wear resistance and compression resistance, and have a wide range of raw materials , the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

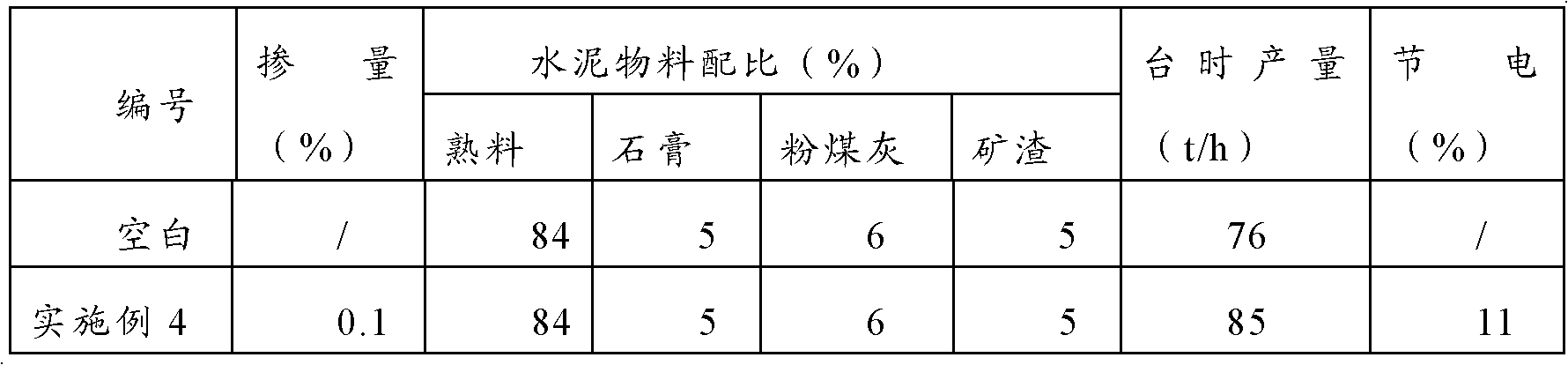

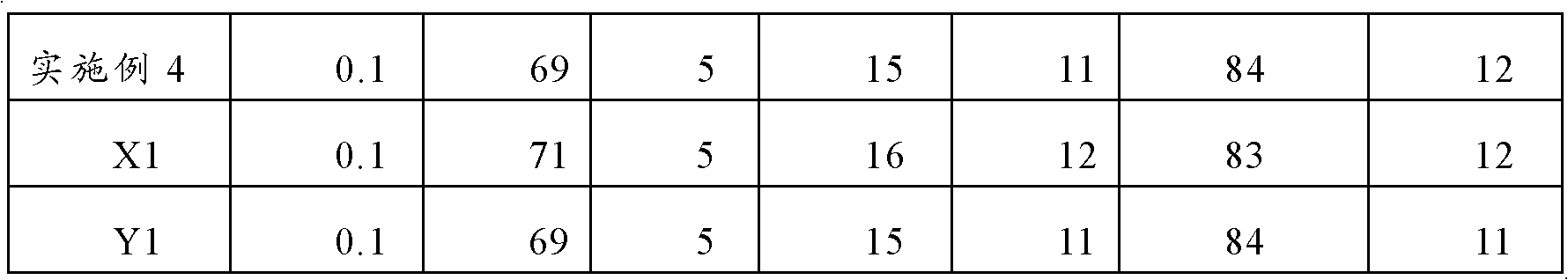

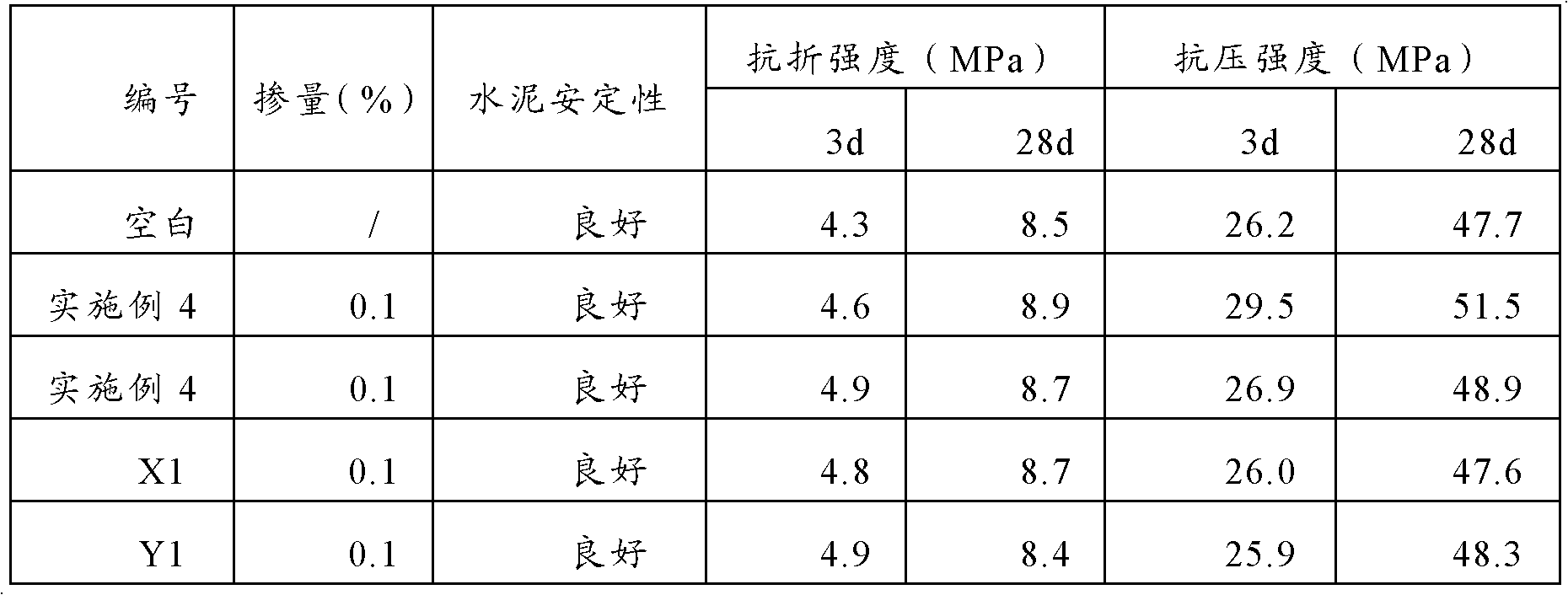

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of modified lignin, comprising:

[0056] mixing lignin and alcohol amine compounds in water to obtain a mixed solution, and adjusting the mixed solution to be alkaline;

[0057] Drop formaldehyde into the mixed solution to react to obtain modified lignin;

[0058] The mass ratio of the lignin, alcohol amine compounds, formaldehyde and water is: (10-15); (10-15): (24-30): (40-50).

[0059] According to the present invention, the preparation of the modified lignin is specifically:

[0060] First, add a certain amount of lignin and water in a reaction kettle equipped with stirring, temperature control, feeding and condensing reflux devices, and adjust the mixed solution to be alkaline with sodium hydroxide, and the alkaline meets the following conditions: pH 9~10, then add diethanolamine into the reaction kettle, raise the temperature to 90~120°C, and finally add formaldehyde solution dropwise slowly into the react...

Embodiment 1

[0070] In the four-neck flask equipped with mechanical stirring, thermometer, feeding funnel, and reflux condenser, add 250kg of lignin and 950kg of water, adjust the pH to 9 to 10 with 10kg of sodium hydroxide, then add 220kg of diethanolamine, and heat up to 95°C, then slowly add 480kg of formaldehyde solution dropwise within 2 hours, react for 5 hours under stirring, and end the reaction to obtain the modified lignin polymer synthetic cement grinding aid.

Embodiment 2

[0072] In the four-neck flask equipped with mechanical stirring, thermometer, feeding funnel, and reflux condenser, add 275kg of lignin and 1000kg of water, adjust the pH to 9-10 with 15kg of caustic soda, then add 250kg of diethanolamine, and heat up to 105°C, then slowly add 510kg of formaldehyde solution dropwise within 2 hours, react with stirring for 6 hours, and end the reaction to obtain the modified lignin polymer synthetic cement grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com