Pervious concrete road for purifying automobile exhaust and construction method of pervious concrete road

A technology for permeable concrete and automobile exhaust, applied in chemical instruments and methods, roads, roads, etc., can solve the problems of inability to completely deal with harmful gases in exhaust gas, poor purification effect, etc., to extend the operating time, purify automobile exhaust, Improves compressive and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

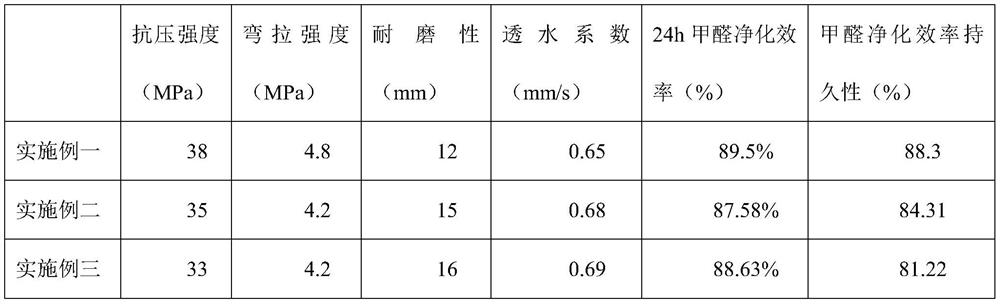

Embodiment 1

[0029] S1 Add 65 parts of aggregate, 20 parts of inorganic cementitious material, 0.5 part of permeable concrete reinforcing agent and 8 parts of water into the mixer for stirring. After stirring evenly, add 1 part of inorganic modified polymer resin and continue stirring until form a homogeneous mixture;

[0030] S2 Transport the evenly stirred mixture to the construction site. The bottom layer of permeable concrete is vibrated and leveled, and the surface layer is polished and smoothed with a cement trowel. After the construction is completed, it is covered and maintained;

[0031] After S3 curing for 7 days, remove the cover and other debris on the surface of the permeable concrete, and then spray the photocatalytic permeable concrete protective agent. The material consumption is 0.3kg / ㎡, and it can be used normally 24 hours after construction.

Embodiment 2

[0033] S1 Add 70 parts of aggregate, 18 parts of inorganic cementitious material, 1.0 part of permeable concrete reinforcing agent and 6 parts of water into the mixer for stirring. After stirring evenly, add 0.5 parts of inorganic modified polymer resin and continue stirring until form a homogeneous mixture;

[0034] S2 Transport the evenly stirred mixture to the construction site. The bottom layer of permeable concrete is vibrated and leveled, and the surface layer is polished and smoothed with a cement trowel. After the construction is completed, it is covered and maintained;

[0035] After 7 days of S3 curing, remove the covering and other debris on the surface of the permeable concrete, and then spray the photocatalytic permeable concrete protective agent. The material consumption is 0.25kg / ㎡, and it can be used normally 24 hours after construction.

Embodiment 3

[0037] S1 Add 75 parts of aggregate, 18 parts of inorganic cementitious material, 0.5 part of permeable concrete reinforcing agent and 7 parts of water into the mixer for stirring. After stirring evenly, add 0.5 part of inorganic modified polymer resin and continue stirring until form a homogeneous mixture;

[0038] S2 Transport the evenly stirred mixture to the construction site. The bottom layer of permeable concrete is vibrated and leveled, and the surface layer is polished and smoothed with a cement trowel. After the construction is completed, it is covered and maintained;

[0039] After S3 curing for 7 days, remove the cover and other debris on the surface of the permeable concrete, and then spray the photocatalytic permeable concrete protective agent. The material consumption is 0.20kg / ㎡, and it can be used normally 24 hours after construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com