Flexible flat wire with good wear-resistant and compression-resistant effects

A technology of flexible flat wires and flat wires, which is applied in the direction of flat/ribbon cables, conductors, insulated cables, etc., can solve the problems of flexible flat copper wire damage, easy winding, and inconvenient disassembly, etc., to improve orderliness, The effect of reducing misalignment and improving the anti-pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

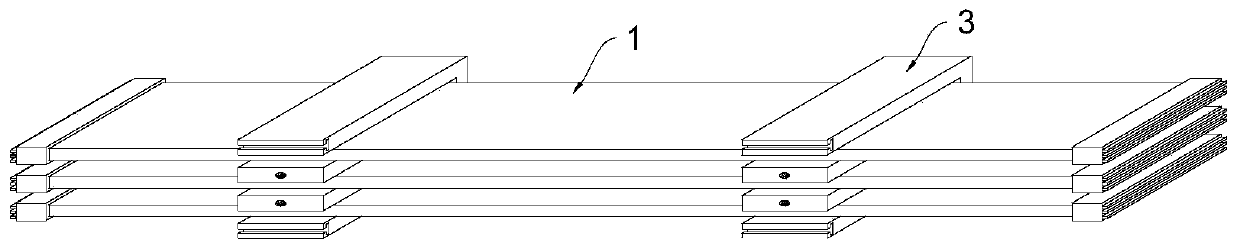

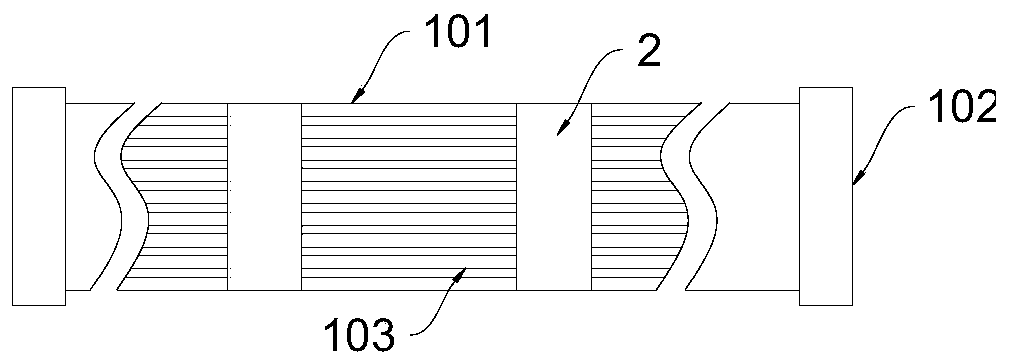

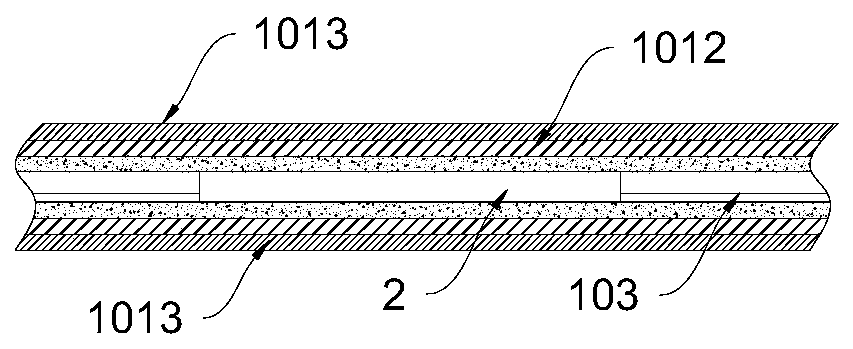

[0025] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a flexible flat cable with good wear resistance and compression resistance of the present invention includes a flat cable body 1, and the flat cable body 1 includes a protective layer 101, two connection ports 102 and several flat cables 103, two connection ports 102 They are respectively arranged at both ends of the protective layer 101, and several flat cables 103 are respectively equidistantly arranged in the protective layer 101, and several elastic pads 2 are equidistantly arranged outside the several flat cables 103, and the exterior of the flat cable body 1 is arranged There are fixing clips 3 for arranging a plurality of flat wire bodies 1. The fixing clips 3 include an inverted U-shaped connection block 301 and several partition plates 302. The inside of the connection block 301 is divided into several partition plates 302. There are several placem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com