Method for increasing sheeting rate of redried finished tobacco sheets

A technology for the percentage of cigarettes in cigarettes and the percentage of sliced cigarettes is applied in the field of improving the percentage of sliced cigarettes in re-baked finished cigarettes, which can solve the problems of difficulty in controlling the stability of cigarette product quality, difficulty in controlling the size of leaves, and energy consumption for breaking and breaking, and thus achieves the goal of promoting The effect of water uniformity and storage alcoholization, energy consumption reduction and coordination improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

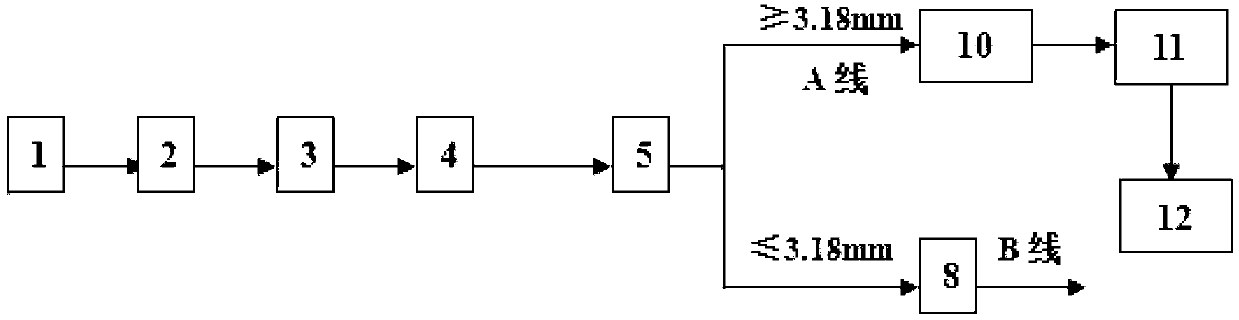

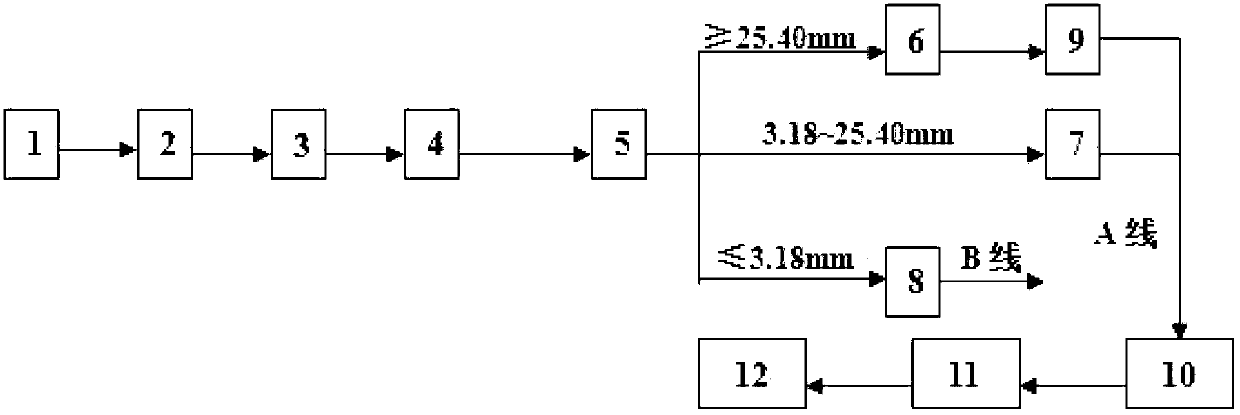

[0019] For Hongda B1F grade tobacco leaves, the existing process (process such as figure 1 Shown) as a comparison, adopt the improved process of the present invention (technical process such as figure 2 shown) for threshing and re-roasting, the specific process is as follows: after testing the raw tobacco temperature is 23.0°C and the moisture content is 15.4%, the temperature and moisture content of the first moistening are respectively set to (56.0±1.0)°C and (18.5±0.5)%. The moistening temperature and moisture are set to (57.0±1.0) ℃ and (19.0±0.5)% respectively; after the stalk leaves are separated, the tobacco sheets are sent to the sifter, and the tobacco sheets with a diameter greater than or equal to 25.40 mm are screened out into a multi-knife classification machine. Cutting equipment, 3.18 ~ 25.40mm sheet tobacco enters the aggregate conveyor belt through No. 1 temporary storage cabinet, and 3.18mm or less sheet tobacco enters the crushed tobacco processing line thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com