Tobacco sheet processing equipment for reducing the length of shredded tobacco

A technology for cutting tobacco length and processing equipment, applied in the direction of processing tobacco, tobacco, solid separation, etc., can solve problems such as affecting equipment operation stability and cigarette product quality, and achieves improving blending uniformity, reducing cut tobacco length, and improving filament rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

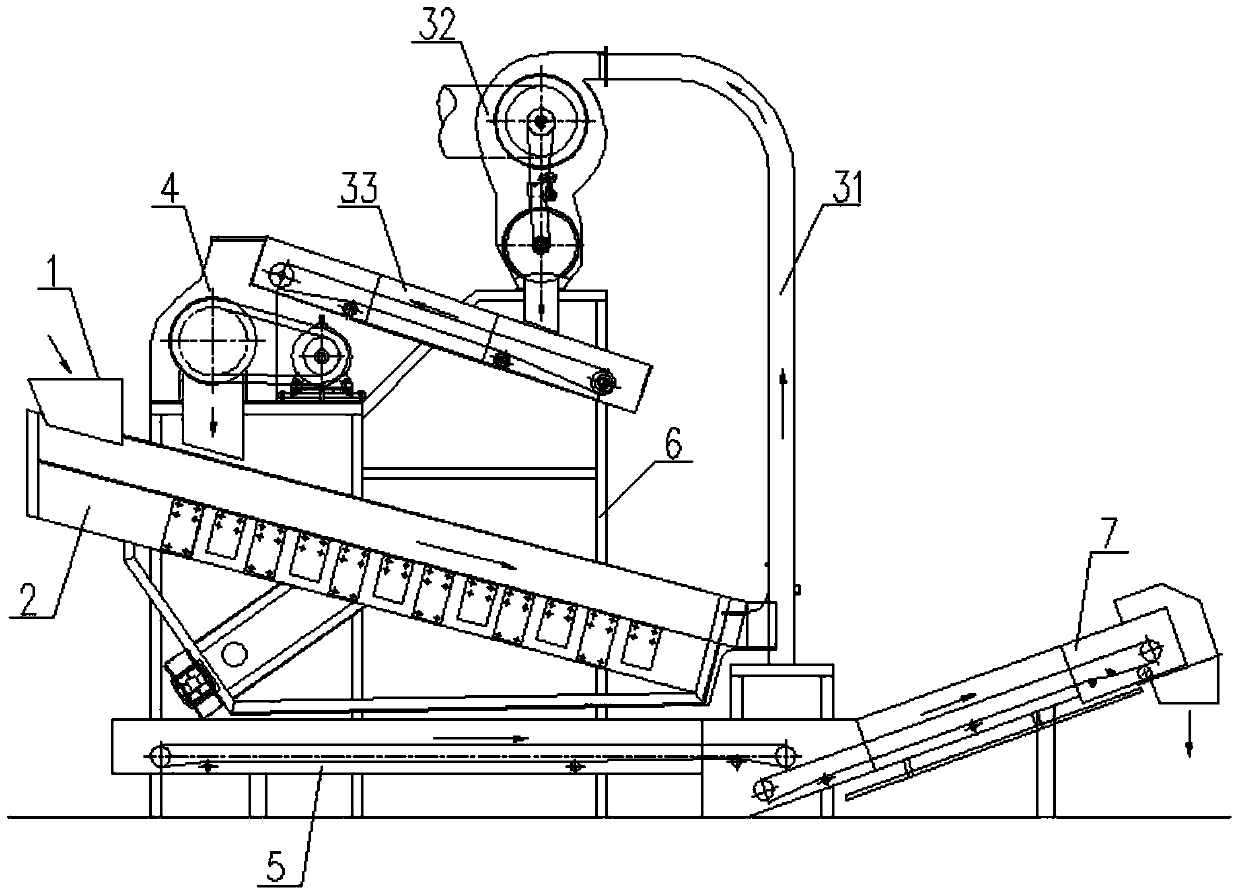

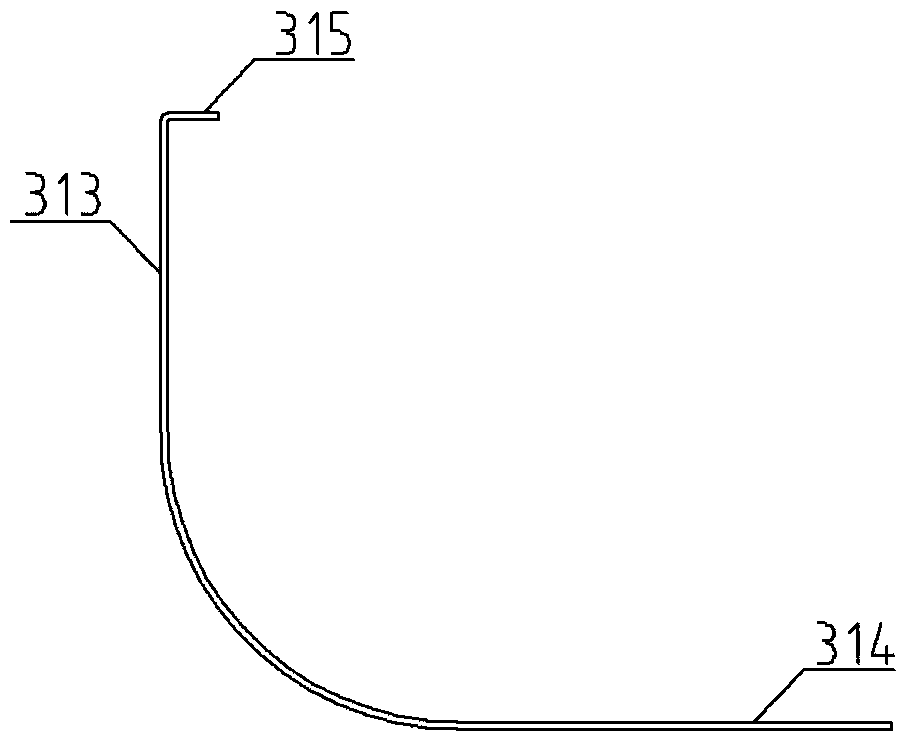

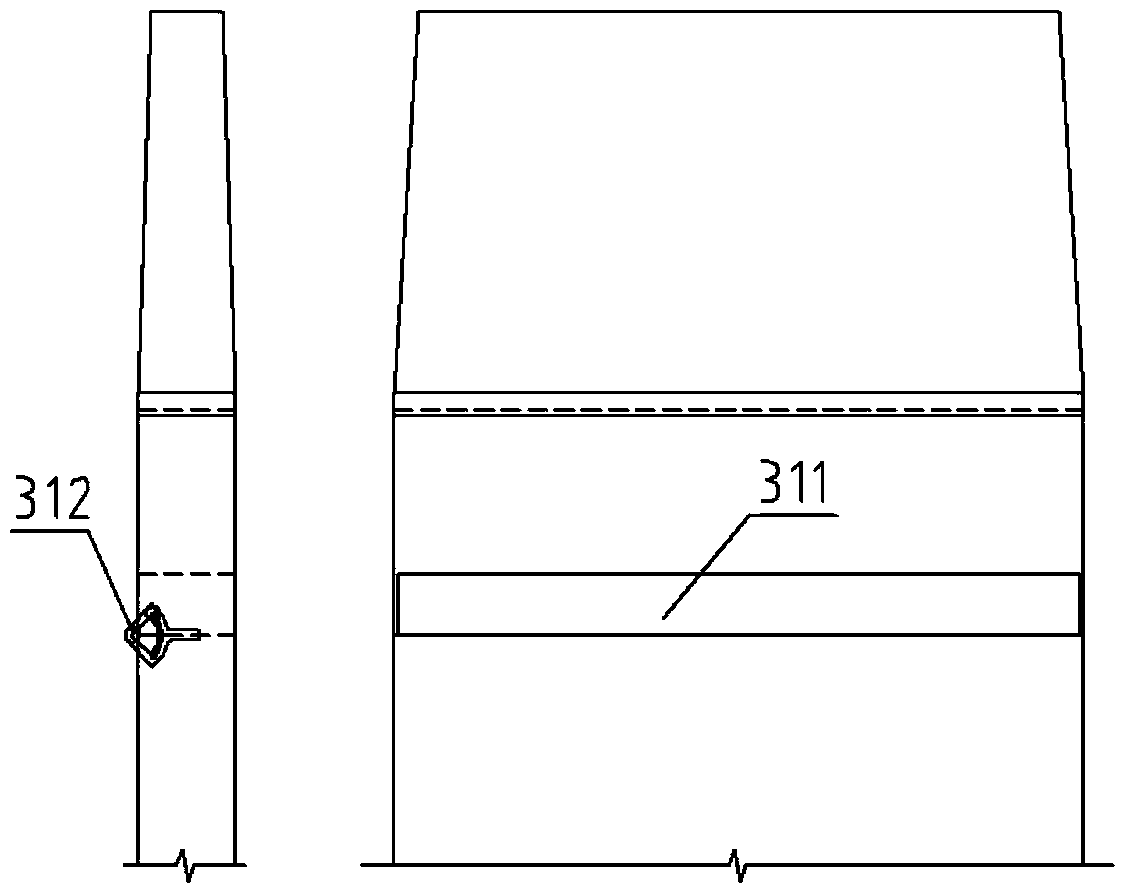

[0043] like figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, a tobacco sheet processing device for reducing the length of shredded tobacco in this embodiment includes a large sheet screening device 2, a conveying device, and a large sheet processing device 4. The discharge end of the large sheet screening device 2 is provided with a feeding port of the conveying device. , the discharge port of the conveying device is connected with the feeding port of the large sheet processing device 4, and the discharging port of the large sheet processing device 4 is set above the feeding end of the large sheet screening device 2. The large sheet screening device 2, the conveying device, the large sheet The processing device 4 forms a circulation loop.

[0044] The feeding hopper 1 of this embodiment is directly installed on the feeding end of the large-screen screening device 2, which can facilitate the throwing of the tobacco chips to be processed into the large-scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com