A Leaf Threshing Method for Reducing the Stem Content of Secondary Processed Sheet Tobacco

A technology of secondary processing and stalk content, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, etc., can solve the problem of high selection and processing costs, and achieve easy implementation in workshop production, reduce the large-scale rate, and improve the medium-scale and small-scale rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments.

[0023] Experimental site: production line of a rebaking factory

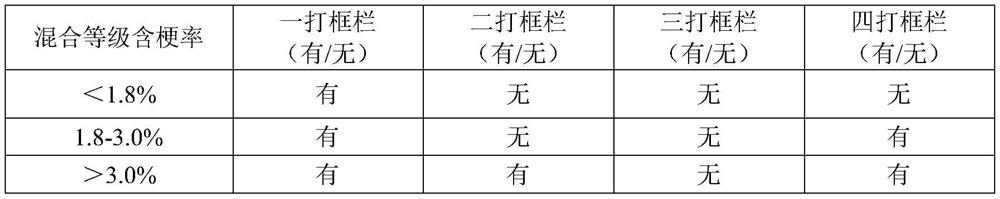

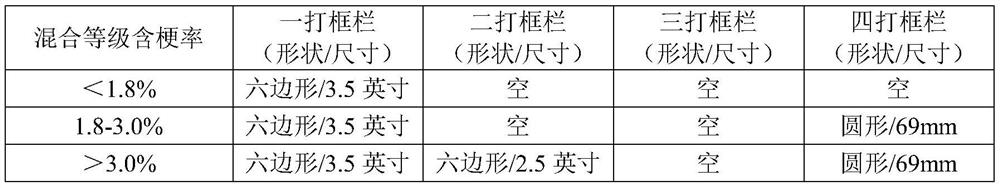

[0024] (1) Before the leaf moistening process, detect the stalk content rate of tobacco leaves of each processing grade. According to the feeding ratio, a total of 7 raw tobacco grades are fed, and 3 secondary finished product grades are formed. According to the stalk content rate 3.0% divide mixed-grade tobacco leaves into three categories, and the specific ratio and stem content are as follows:

[0025]

[0026]

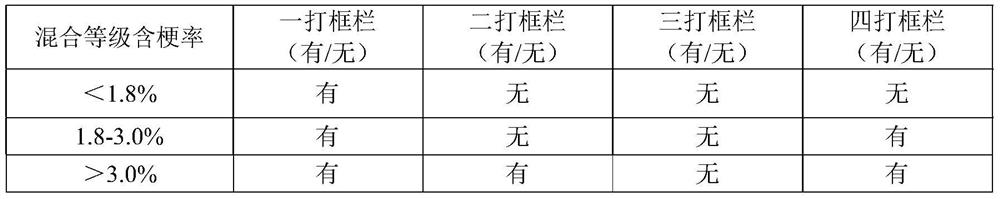

[0027] (2) According to the detection results of the stalk content rate in the leaves of the secondary formula processing grade, combined with the proportion, calculate the compound stalk content rate of the tobacco to be processed.

[0028] After the mixed grades have undergone online selection, leaf moistening, and impurity removal, the leaf threshing process is carried out with reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com