High-performance 17-4PH stainless steel material and high-pressure heat treatment method, manufacturing method and application thereof

A heat treatment method and stainless steel technology, applied in the field of heat treatment of metal materials, can solve the problems of low production efficiency and long time consumption, and achieve the effects of improving production efficiency, convenient production and implementation, and improving comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

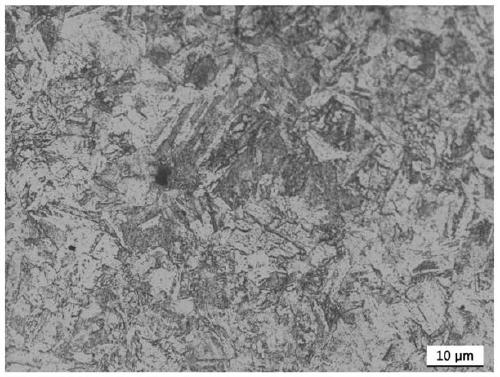

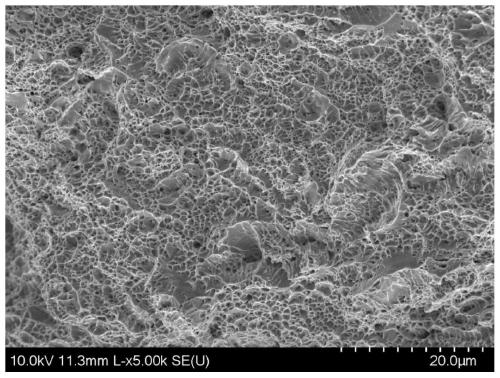

Image

Examples

preparation example Construction

[0040] The preparation method of a kind of high-performance 17-4PH stainless steel material that the embodiment of the present invention provides, comprises:

[0041] 17-4PH stainless steel material is obtained by additive manufacturing;

[0042] Then, the 17-4PH stainless steel material is heat-treated using the high-pressure heat treatment method for the 17-4PH stainless steel material provided in the embodiment of the present invention.

[0043] The high-performance 17-4PH stainless steel material provided by the embodiment of the present invention or prepared by the method provided by the embodiment has good comprehensive mechanical properties and can be widely used in aerospace, petrochemical, nuclear industry and other fields.

Embodiment 1

[0046]A high-pressure heat treatment method for 17-4PH stainless steel material, comprising the following steps:

[0047] High-pressure solution treatment: place the 17-4PH stainless steel material obtained by additive manufacturing in a hot isostatic pressing cylinder, and under the condition of an initial pressure of 30MPa, increase the temperature and pressurize at the same time, the heating rate is 20°C / min, and heat to 1040 ℃, while increasing the air pressure of the cylinder to 150MPa, heat preservation and pressure holding for 2 hours; then cool down to 480℃ at a cooling rate of 1000℃ / min under high pressure;

[0048] High-pressure aging treatment: heat preservation at 480°C for 4 hours, then cool to room temperature at 1000°C / min under high pressure;

[0049] Among them, during the high-pressure solid solution and high-pressure aging treatment of 17-4PH stainless steel materials, the samples are always placed in the hot isostatic pressing cylinder, and the cylinder pre...

Embodiment 2

[0052] A high-pressure heat treatment method for 17-4PH stainless steel material, comprising the following steps:

[0053] High-pressure solution treatment: place the 17-4PH stainless steel material obtained by additive manufacturing in a hot isostatic pressing cylinder, and under the condition of an initial pressure of 30MPa, increase the temperature and pressurize at the same time, the heating rate is 20°C / min, and heat to 1040 ℃, at the same time, the air pressure of the cylinder is increased to 150MPa, and the temperature is maintained for 2 hours; then the temperature is lowered to 480℃ at a cooling rate of 10℃ / min under high pressure;

[0054] High-pressure aging treatment: heat preservation at 480°C for 8 hours, then cool to room temperature at 1000°C / min under high pressure;

[0055] Among them, during the high-pressure solid solution and high-pressure aging treatment of 17-4PH stainless steel materials, the samples are always placed in the hot isostatic pressing cylin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com