A method for preparing multiphase strengthened ferritic alloy

A ferrite and alloy technology, applied in the field of metal dispersion strengthening, can solve the problems of high energy consumption of high-energy ball milling, low preparation efficiency, high impurity oxygen content, etc., and achieve the effect of eliminating residual pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

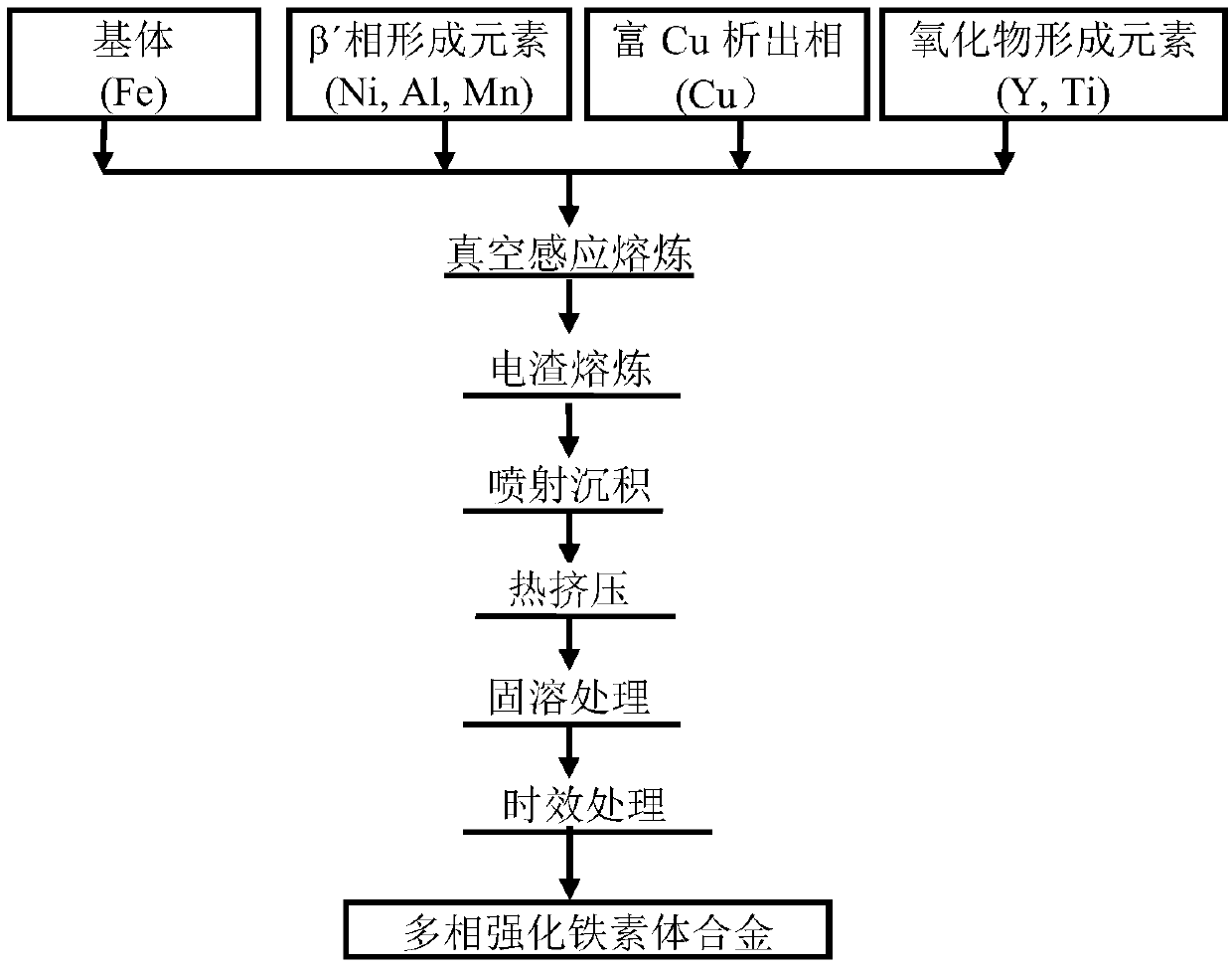

Method used

Image

Examples

Embodiment 1

[0012] Example 1: The composition is 5Ni-1Al-3Mn-0.1Y 2 o 3 Preparation of multi-phase strengthened ferritic alloy with oxide disperse phase of -0.3Ti-0.5Cu-balance Fe

[0013] Iron block, Fe-Mn alloy, Ni-Al alloy, Fe-Y alloy, Fe-Ti alloy and copper block are used as raw materials, and the purity of each raw material is greater than 99.9%. Metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 5 minutes. After washing with alcohol, dry in an oven at 60°C for 90 minutes. Weigh according to the composition of the target multiphase strengthened ferrite alloy, the composition of the target multiphase strengthened ferrite alloy is: 5Ni-1Al-3Mn-0.1Y 2 o 3 -0.3Ti-0.5Cu-balance Fe. The intermediate alloy is smelted in a vacuum induction furnace. During the smelting process, a CaO ceramic crucible is used to control the vacuum degree of 0.05-0.2Pa. After all the raw materials are melted, the melting power i...

Embodiment 2

[0014] Example 2: The composition is 5Ni-1Al-3Mn-0.2Y 2 o 3 Preparation of multi-phase strengthened ferritic alloy with oxide disperse phase of -0.3Ti-0.5Cu-balance Fe

[0015]Iron block, Fe-Mn alloy, Ni-Al alloy, Fe-Y alloy, Fe-Ti alloy and copper block are used as raw materials, and the purity of each raw material is greater than 99.9%. Metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 10 minutes. After washing with alcohol, dry in an oven at 70°C for 60 minutes. Weigh according to the composition of the target multiphase strengthened ferrite alloy, the composition of the target multiphase strengthened ferrite alloy is: 5Ni-1Al-3Mn-0.2Y 2 o 3 -0.3Ti-0.5Cu-balance Fe. The intermediate alloy is smelted in a vacuum induction furnace. During the smelting process, a CaO ceramic crucible is used to control the vacuum degree of 0.05-0.2Pa. After all the raw materials are melted, the melting power i...

Embodiment 3

[0016] Example 3: The composition is 5Ni-1Al-3Mn-0.25Y 2 o 3 Preparation of multi-phase strengthened ferritic alloy with oxide disperse phase of -0.3Ti-0.5Cu-balance Fe

[0017] Iron block, Fe-Mn alloy, Ni-Al alloy, Fe-Y alloy, Fe-Ti alloy and copper block are used as raw materials, and the purity of each raw material is greater than 99.9%. Metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 15 minutes. After washing with alcohol, dry in an oven at 75°C for 45 minutes. Weigh according to the composition of the target multiphase strengthened ferrite alloy, the composition of the target multiphase strengthened ferrite alloy is: 5Ni-1Al-3Mn-0.25Y 2 o 3 -0.3Ti-0.5Cu-balance Fe. The intermediate alloy is smelted in a vacuum induction furnace. During the smelting process, a CaO ceramic crucible is used to control the vacuum degree of 0.05-0.2Pa. After all the raw materials are melted, the melting powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com