Microwave hot isostatic pressing sintering furnace for post-sintering of dental zirconia ceramics

A hot isostatic pressing sintering, zirconia ceramic technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of difficult removal and poor reliability, and achieve simple materials, low maintenance costs, and increased density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

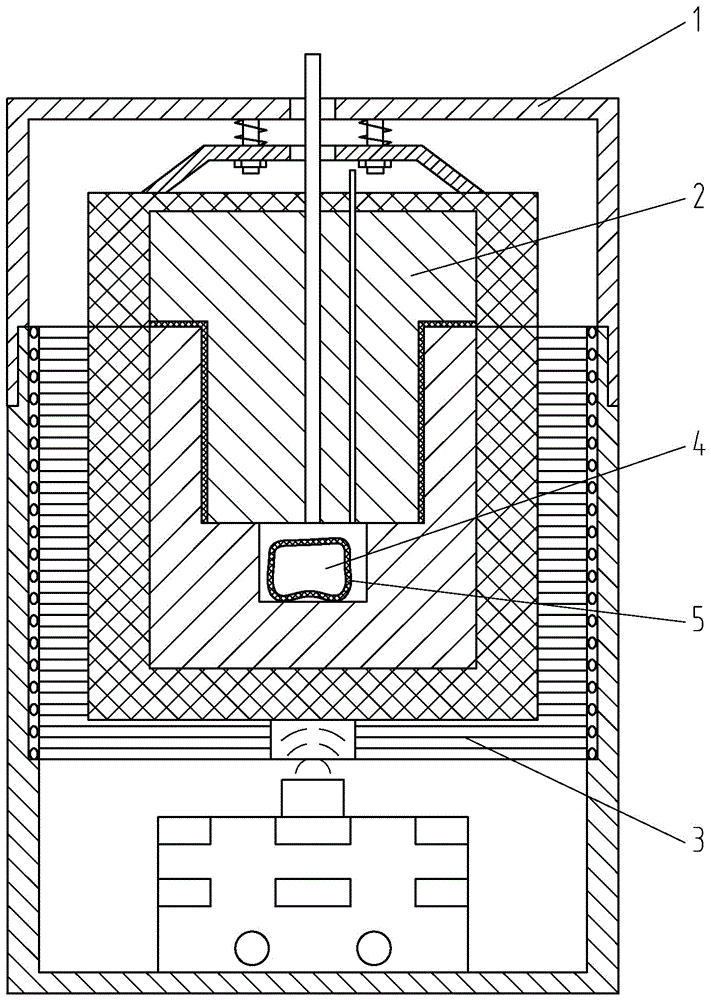

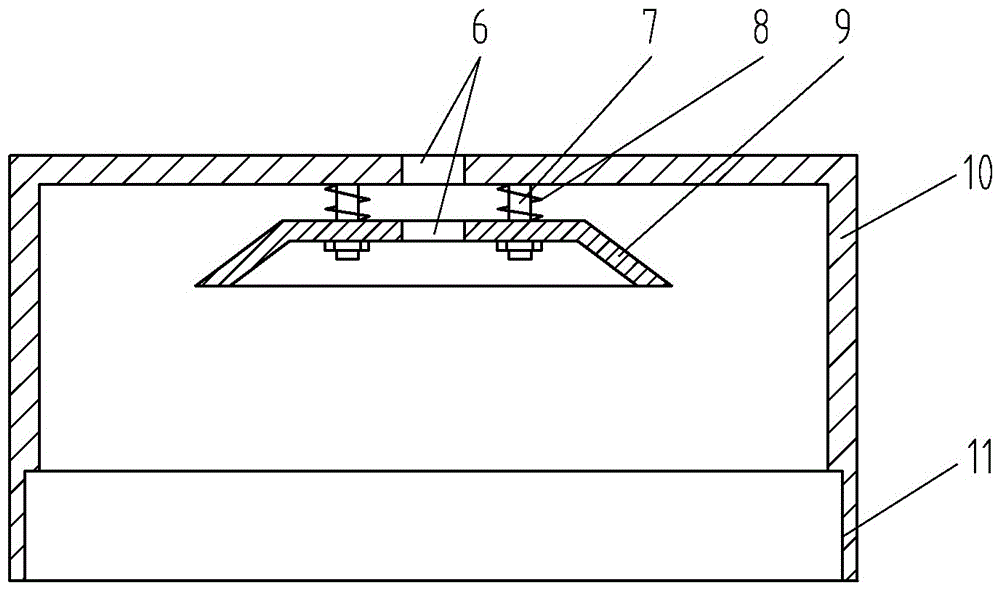

[0023] Such as figure 1 As shown, the microwave hot isostatic pressing sintering furnace of the present invention comprises a loam cake 1, a plug 2 and a furnace body 3, wherein the plug 2 is inserted above the furnace body 3, and the loam cake 1 fastens the furnace body 3 from above and closes the plug 2 Create top pressure.

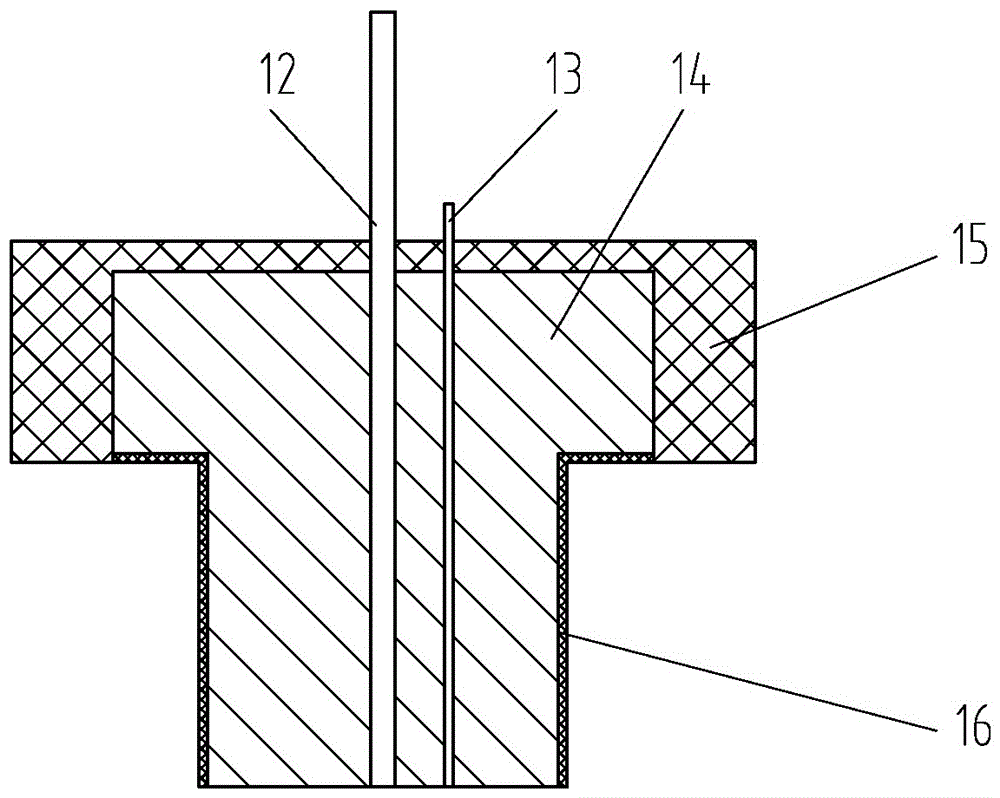

[0024] Such as Figure 4 As shown, the top of the body of furnace 3 is provided with a high-pressure cylinder 19 made of silicon carbide, and the cylinder hole at the center of the top surface of the high-pressure cylinder 19 is a second-level stepped hole, wherein the upper-step hole is a plug hole 18, The lower step hole is the furnace 17, and the outer side of the high-pressure cylinder 19 is wrapped with a lower heat insulation layer 20 formed by winding quartz fibers. There is a cooling layer 23 constructed of water-cooled copper tubes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com