a kind of si 3 no 4 Ceramic material and its preparation method

A ceramic material, -si3n492 technology, applied in the field of silicon nitride ceramics preparation, can solve the problems such as the reduction of wear resistance of silicon nitride ceramics, and achieve the effects of eliminating residual pores, excellent comprehensive performance and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of Si 3 N 4 Ceramic material and preparation method thereof, comprising the following steps:

[0039] S1: Weigh 95g Si 3 N 4 , 1.73g Al 2 o 3 , 1.27g Y 2 o 3 , 1.00g Fe 2 o 3 A total of 100g and 1.00g AlN;

[0040] S2: The mixed powder in step S1 is configured into a slurry with a certain solid content, and the planetary ball mill is 3h, and the rotating speed is 400rpm;

[0041] S3: Grinding after drying the slurry obtained in step S2, passing through a 400-mesh sieve and preforming under a pressure of 20 MPa by dry pressing, and then forming by cold isostatic pressing at 300 MPa;

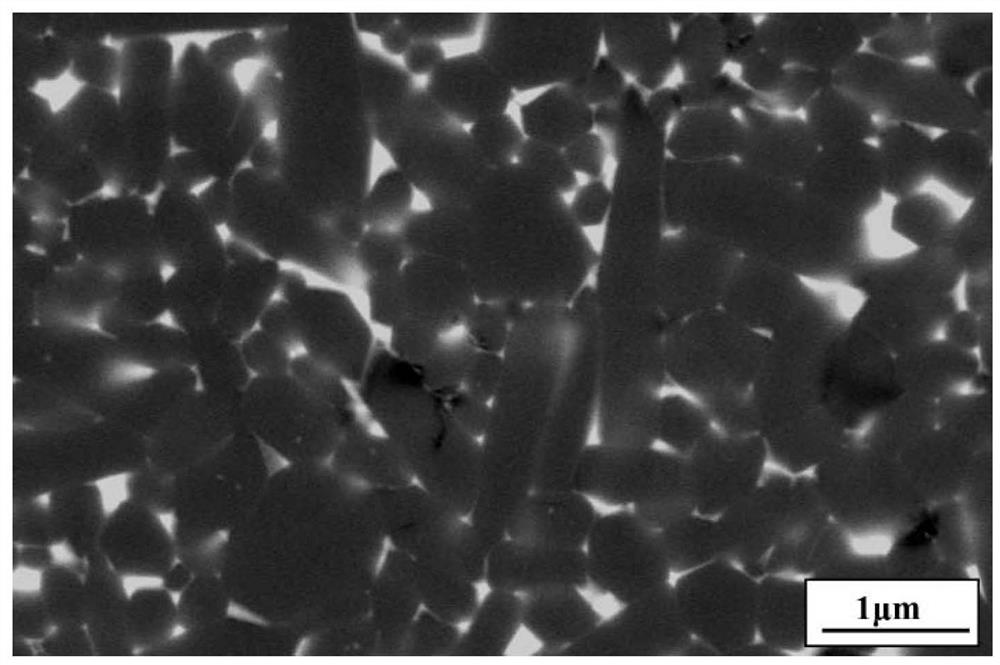

[0042] S4: the ceramic biscuit obtained in step S3 is put into a BN mould, and placed in a gas pressure sintering furnace, filled with N 2 As a protective gas, sinter at 1750°C and 2MPa pressure for 240 minutes, then perform hot isostatic pressing at 1700°C for 2.5 hours at 200MPa, the relative density is 99.4%, and the bending strength is 1305.7± 15.2MPa, fracture toughn...

Embodiment 2

[0044] A kind of Si 3 N 4 Ceramic material and preparation method thereof, comprising the following steps:

[0045] S1: Weigh 95g Si 3 N 4 , 0.6g Al 2 o 3 , 2.65g Y 2 o 3 , 0.75g Fe 2 o 3 A total of 100g and 1.00g AlN;

[0046] S2: The mixed powder in step S1 is configured into a slurry with a certain solid content, and the planetary ball mill is 3h, and the rotating speed is 400rpm;

[0047] S3: Grinding after drying the slurry obtained in step S2, passing through a 400-mesh sieve and preforming under a pressure of 20 MPa by dry pressing, and then forming by cold isostatic pressing at 300 MPa;

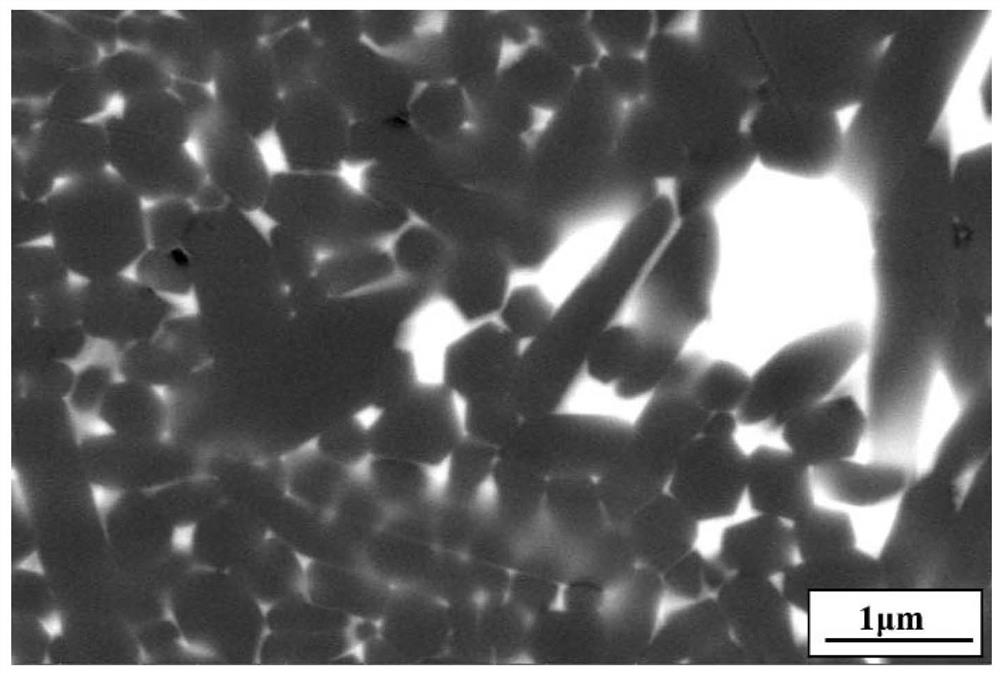

[0048] S4: the ceramic biscuit obtained in step S3 is put into a BN mould, and placed in a gas pressure sintering furnace, filled with N 2 As a protective gas, sinter at 1750°C and 2MPa pressure for 240 minutes, then carry out hot isostatic pressing at 1700°C, holding time for 1h, and pressure 200MPa, that is, the relative density is 99.3%, and the bending strength is 1302....

Embodiment 3

[0050] A kind of Si 3 N 4 Ceramic material and preparation method thereof, comprising the following steps:

[0051] S1: Weigh 95g Si 3 N 4 , 2.01g Al 2 o 3 , 1.49g Y 2 o 3 , 0.75g Fe 2 o 3 And 0.75g AlN a total of 100g;

[0052] S2: The mixed powder in step S1 is configured into a slurry with a certain solid content, and the planetary ball mill is 3h, and the rotating speed is 400rpm;

[0053] S3: Grinding after drying the slurry obtained in step S2, passing through a 400-mesh sieve and preforming under a pressure of 20 MPa by dry pressing, and then forming by cold isostatic pressing at 300 MPa;

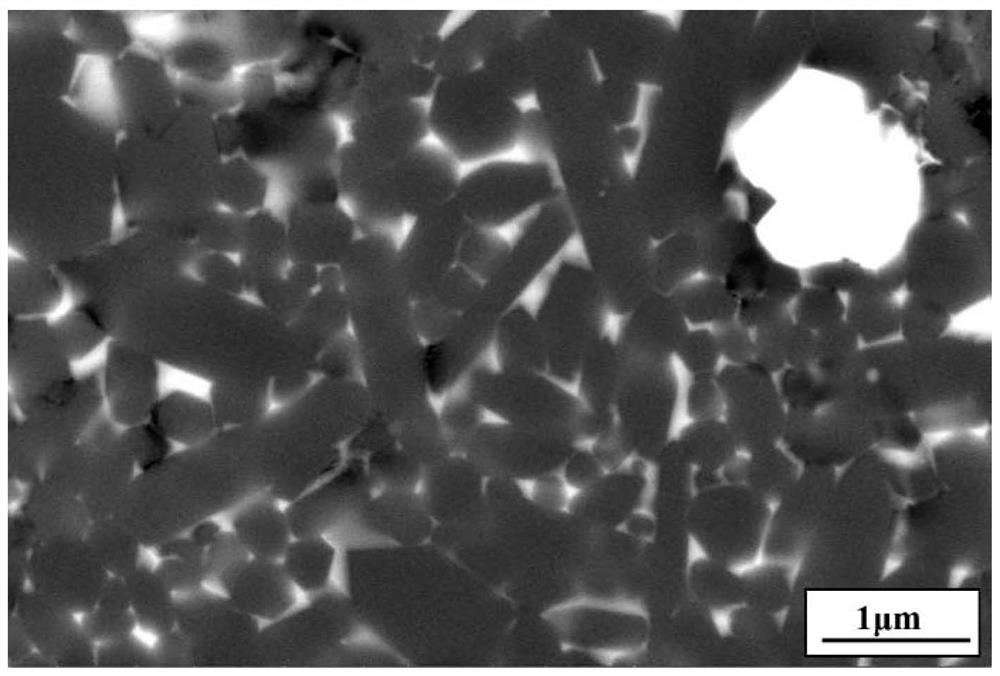

[0054] S4: the ceramic biscuit obtained in step S3 is put into a BN mould, and placed in a gas pressure sintering furnace, filled with N 2 As a protective gas, sinter at 1750°C and 2MPa pressure for 240 minutes, and then perform hot isostatic pressing at 1650°C for a holding time of 0.5h and an air pressure of 150MPa. The relative density is 99.6%, and the bending strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com