Processing technology reducing large leaf rate of leaves

A processing technology and large-scale technology, which is applied in the field of processing technology to reduce the large-scale rate of blades, can solve the problems of easy increase in the fragment rate, reduce the large-scale rate, and increase the workload of the leaf topper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

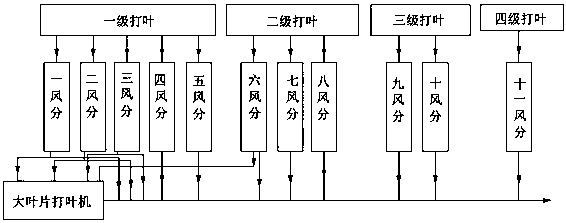

[0025] Embodiment 1 of the present invention provides a processing technology for reducing the large blade rate of four strikes and eleven wind subunits. The flow chart is as follows figure 1 shown. A processing technique for reducing the large blade rate, comprising the following steps:

[0026] (1) Send the pretreated tobacco leaves with a moisture content of 25% to the four-threshing and eleven-threshing unit, and divide the first three winds (the first wind, the second wind, the third wind) and the second-level threshing The tobacco leaves on the vibrating trough at the outlet of the previous air division (six wind divisions) pass through a sieve with a size of 25.4 mm×25.4 mm, and then are sent to the large-blade leaf thresher for secondary threshing;

[0027] (2) The medium and small leaves that have been processed by the large leaf thresher for the second time will flow into the confluence belt and merge with the current batch of tobacco leaf materials for subsequent p...

Embodiment 2

[0029] Embodiment 2 of the present invention provides a processing technology for reducing the large blade rate of a four-strike eleven-air subunit, including the following steps:

[0030] (1) Send the pretreated tobacco leaves with a moisture content of 20% to the four-threshing and eleven-wind sub-unit, and divide the first two winds (first wind, second wind,) of the first-level threshing and the second-level threshing The tobacco leaves on the vibrating trough at the outlet of the first two wind points (six wind points, seven wind points) are sent to the large leaf thresher for secondary leaf thresher after passing through the vibrating screen with a size of 25.4 mm×25.4 mm;

[0031] (2) The medium and small leaves that have been processed by the large leaf thresher for the second time will flow into the confluence belt and merge with the current batch of tobacco leaf materials for subsequent processing. After the leaf threshing and air separation treatment by the process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com