Device for improving charging front blade size uniformity and method thereof

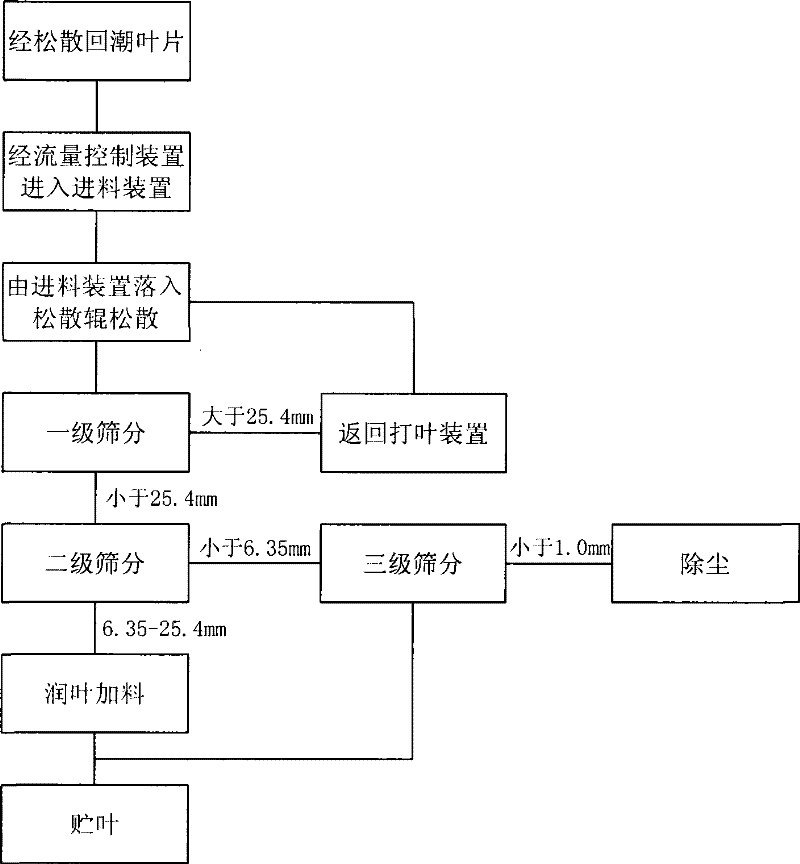

A technology with uniform size and leaves, which is applied in the preparation of tobacco, application, tobacco, etc., can solve the problems of easy folding of leaves, excessive tobacco filaments, winding and agglomeration, etc., to improve the uniformity of leaves, improve screening efficiency, and improve The effect of medium rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

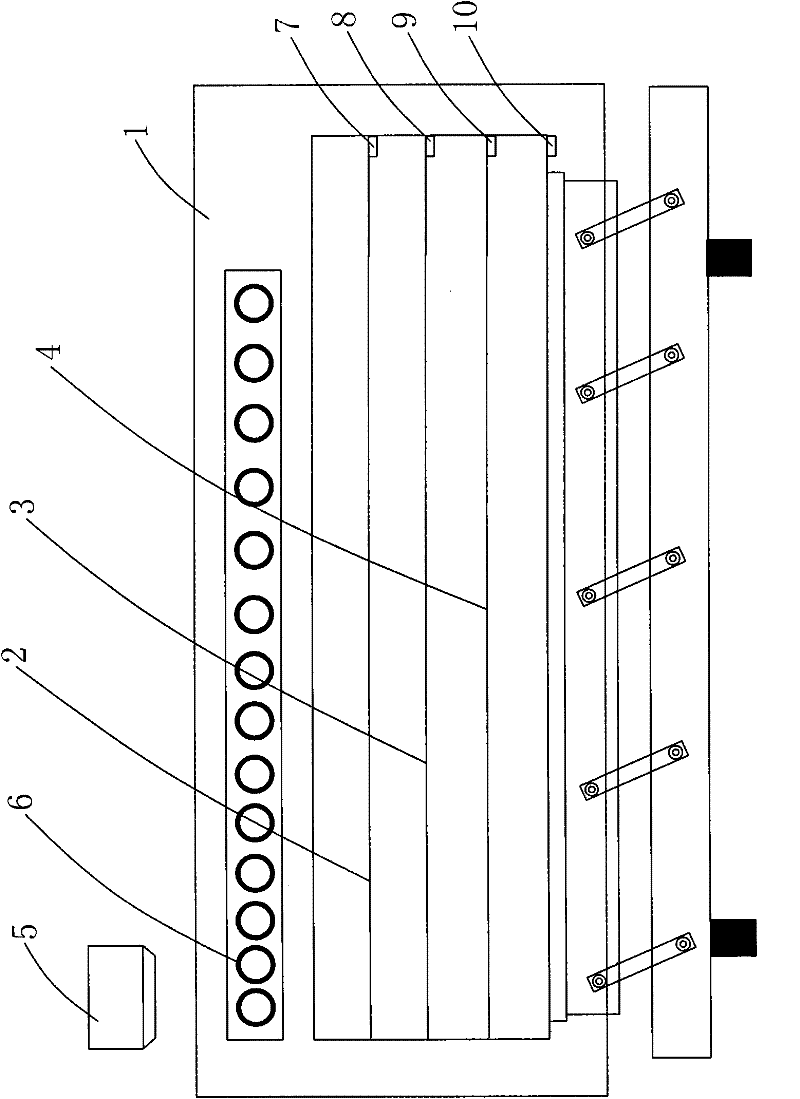

[0027] Example: Combine figure 2 , the screening equipment of the present embodiment is used to improve the uniformity of the blade size before feeding, and the equipment includes: a vibrating screen 1 arranged on a frame, and the vibrating screen has a first layer of screen cloth 2 from top to bottom, The second layer of screen cloth 3 and the third layer of screen cloth 4, and the meshes of each screen cloth from top to bottom decrease successively, a feed device 5 is set above one end of the vibrating screen, and the other side of the vibrating screen relative to the feed device Each layer of screen at one end has a discharge port, and a plurality of loose rollers 6 are arranged in parallel between the feeding device 5 and the first layer of screen 2, and the axis of each loose roller is arranged along the width direction of the vibrating screen 1. Of course, loose The axis of the roller can be parallel to the width direction of the vibrating screen, or form a certain angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com