Caked tobacco powder loosening device

A tobacco powder and loosening technology, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of time-consuming and laborious, and low loosening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

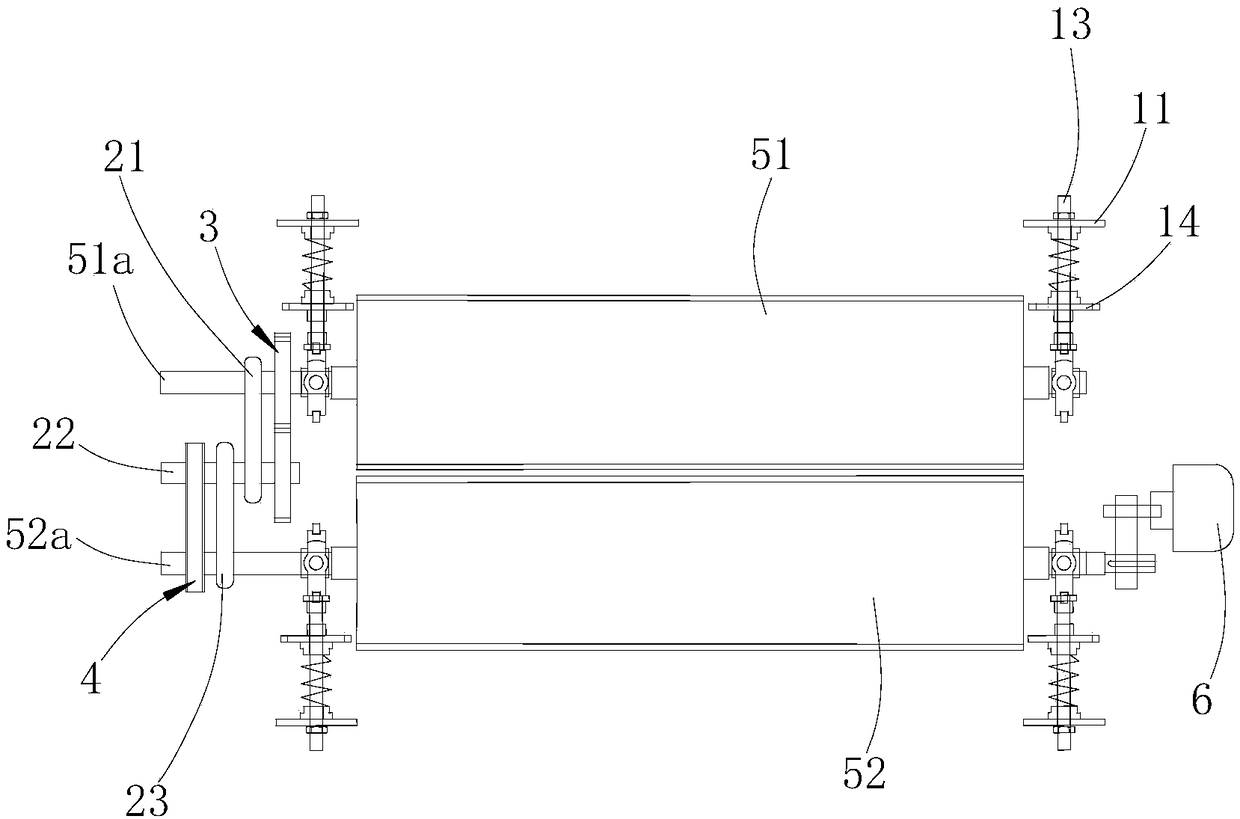

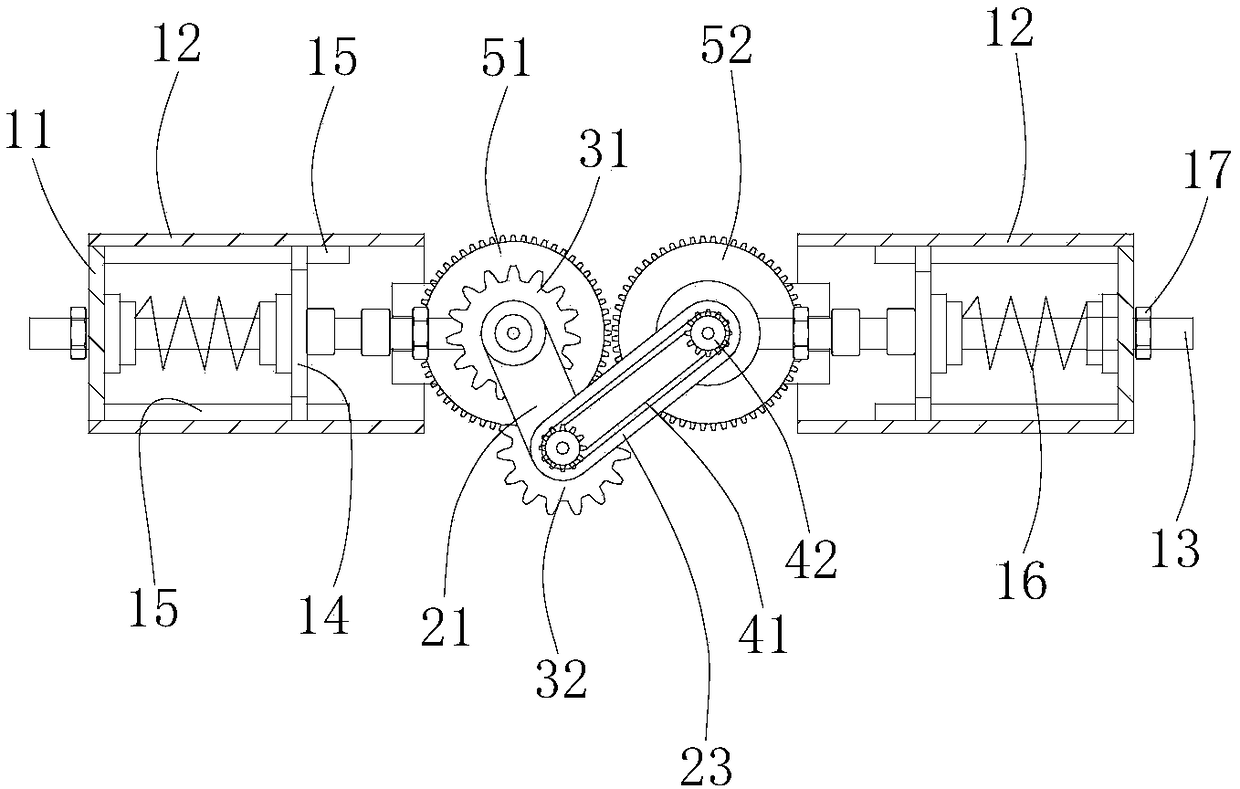

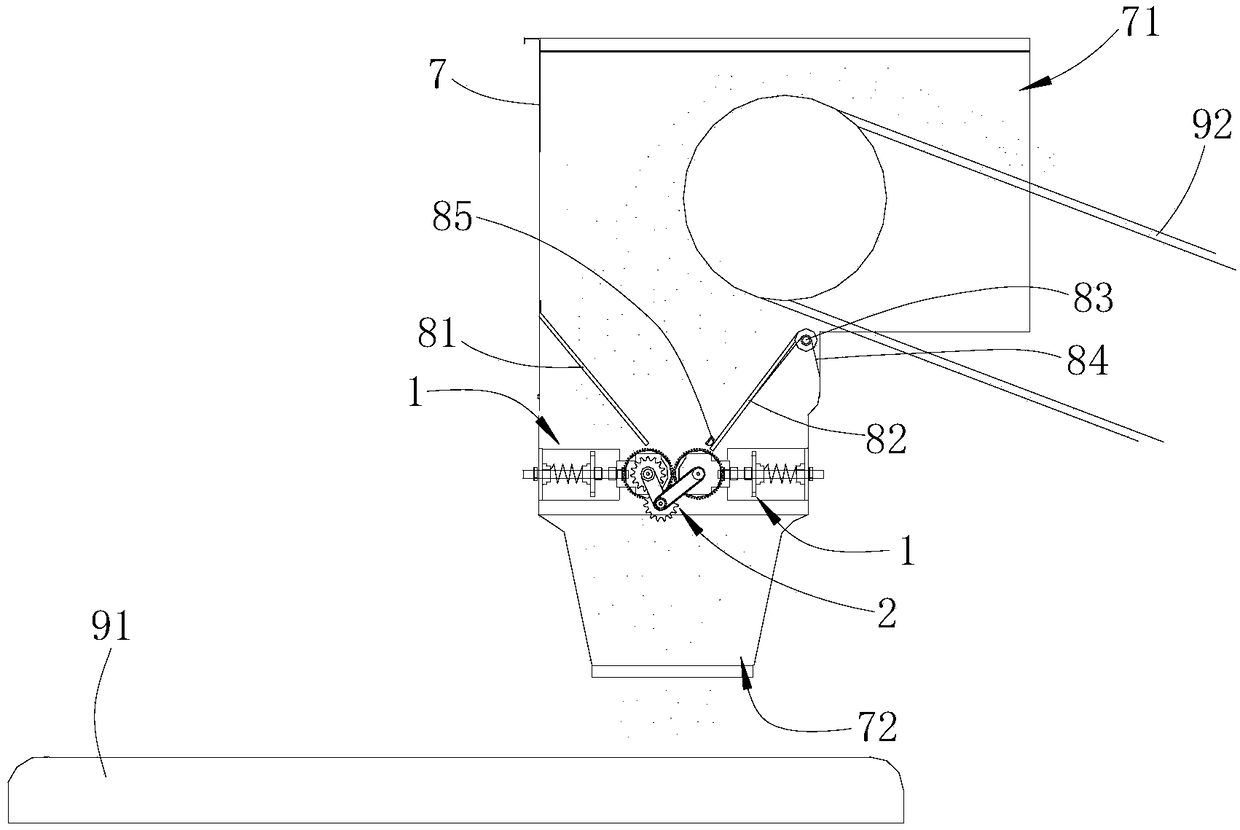

[0023] Such as Figures 1 to 3 Shown (in order to more clearly reflect the internal structure of the agglomerated soot loosening device, figure 1 The limit cover 12 and the guide rail 15 of the translation assembly 1 are omitted in the image 3 The wall thickness of the housing 7 and the limit cover 12 is omitted).

[0024] The agglomerated tobacco powder loosening device includes a housing 7, a first pressing roller 51, a second pressing roller 52, a pre-screen assembly, a vibrating screen 91, a rotating shaft adjusting unit and a driving unit.

[0025] The casing 7 is provided with a passage for the tobacco powder raw material to pass through, the upper part of the casing 7 is provided with a feed port 71 for the tobacco powder raw material to enter the passage, and the lower part of the casing 7 is opened with a discharge port 72 for the tobacco powder raw material discharge channel ( exit), the first pressure roller 51 and the second pressure roller 52 are in the channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com