Raw material screening device for biomedical manufacturing

A screening device and biomedical technology, which is applied in the fields of filter screening, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of small size and weight of impurities, screening out impurities, and inability to take out sieve materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

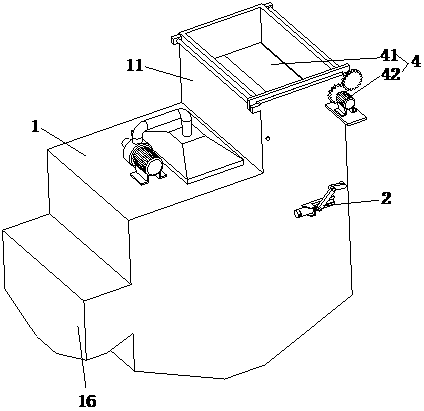

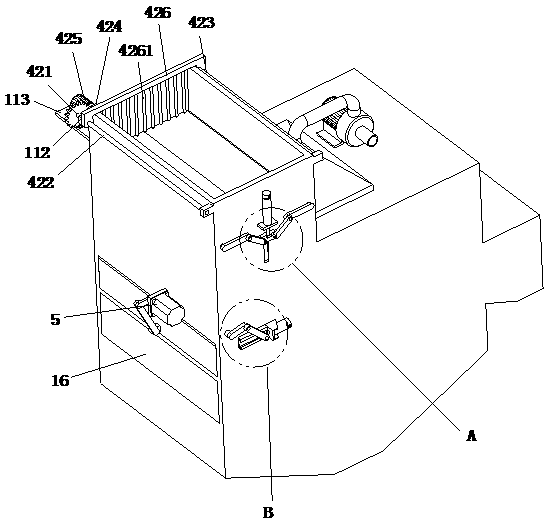

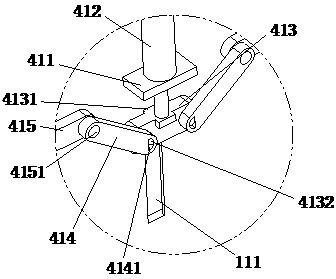

[0027] Below, combined with Figure 1 to Figure 9 And specific embodiment, the present invention is described further:

[0028]A raw material screening device for biomedicine manufacturing, comprising a screening housing 1, a primary screening mechanism 2 and a secondary screening mechanism 3, the top of the screening housing 1 is provided with a feed channel 11 communicating with the inside thereof, and the feeding A raw material loosening mechanism 4 is provided in the material channel 11, and an impurity receiving box 12 and an L-shaped bearing plate 13 are arranged in the screening housing 1 in sequence along the vertical direction, and the preliminary screening mechanism 2 is located in the impurity receiving area. directly above the box 12, the feed channel 11 is located directly above the primary screening mechanism 2, the secondary screening mechanism 3 is installed on the bearing plate 13, and a There is a protective screen 14, and one end of the screening housing 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com