Lauter tun

A filter barrel and guide rod technology, which is applied in the field of filter barrels to achieve optimized results, low flow resistance, and improved loosening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

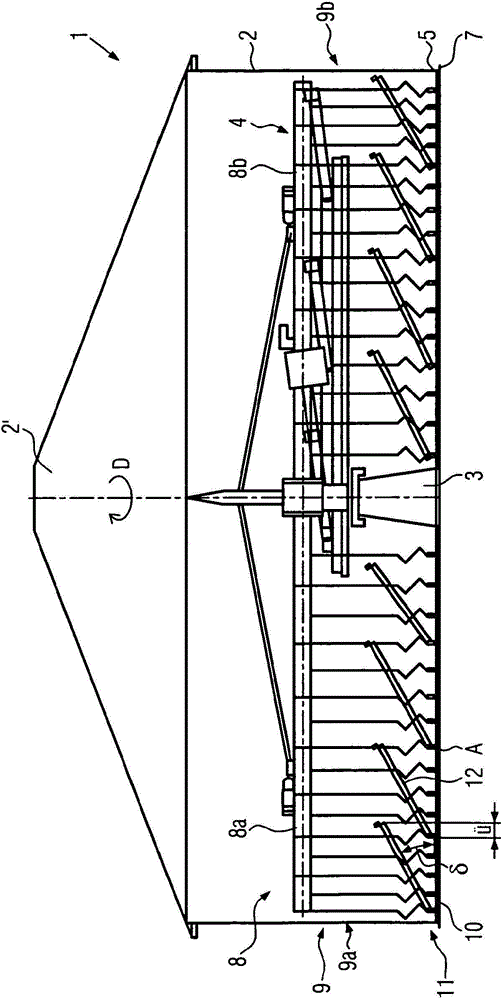

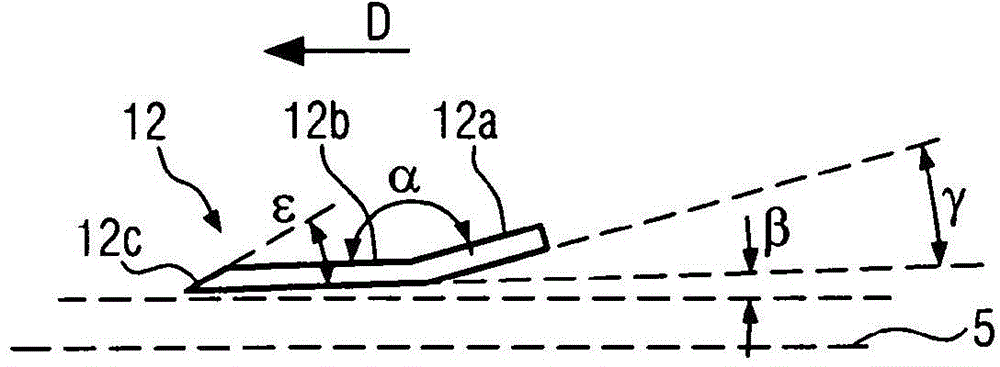

[0028] figure 1 The height shows a schematic view of a longitudinal section of the lauter tun 1 . The lauter tun 1 comprises: a generally cylindrical housing 2 for containing malt pulp; and a drive shaft 3 arranged on a vertical centerline 2' of the lauter tun 1 around which rake means 4 are driven. 'Turn. Furthermore, during operation, the rake device 4 can be adjusted up and down by a lifting device not shown.

[0029] The housing 2 comprises a so-called false bottom 5, which is arranged at a certain distance above a collection chamber 7, in which the liquid phase containing refined juice (filtered wort) discharged from the malt pulp and washed with jet water is collected , for further beer making and can be withdrawn.

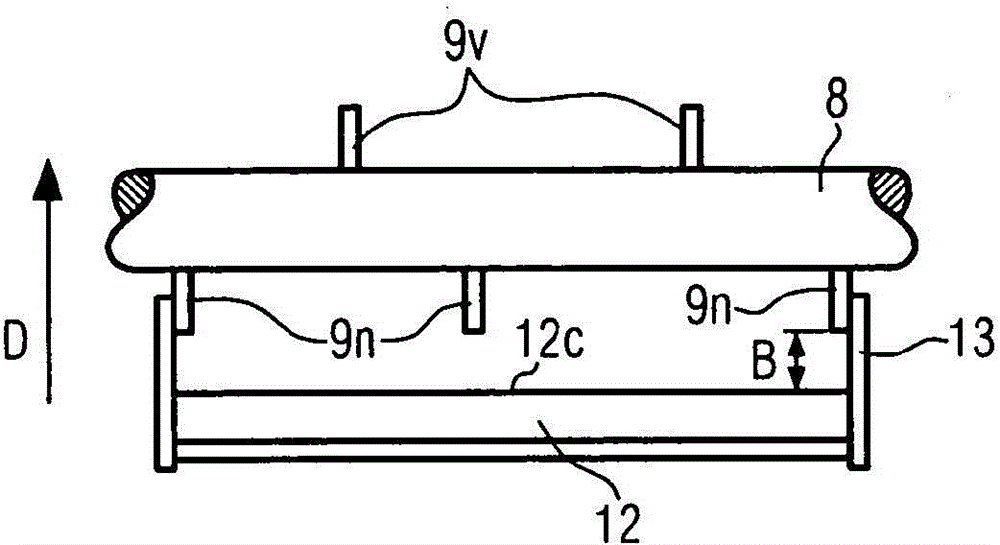

[0030] The rake device 4 generally comprises at least one (preferably several) rake arms 8, of which only two rake arms 8a and 8b diametrically opposite with respect to the center line 2' are shown here. The rake arms 8a, 8b are arranged above the maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com