High blast temperature system of blast furnace hot blast stove

A hot blast stove and blast temperature technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems that hot blast stoves cannot achieve a blast temperature above 1200°C, and achieve the effects of compact layout, low investment and transformation costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

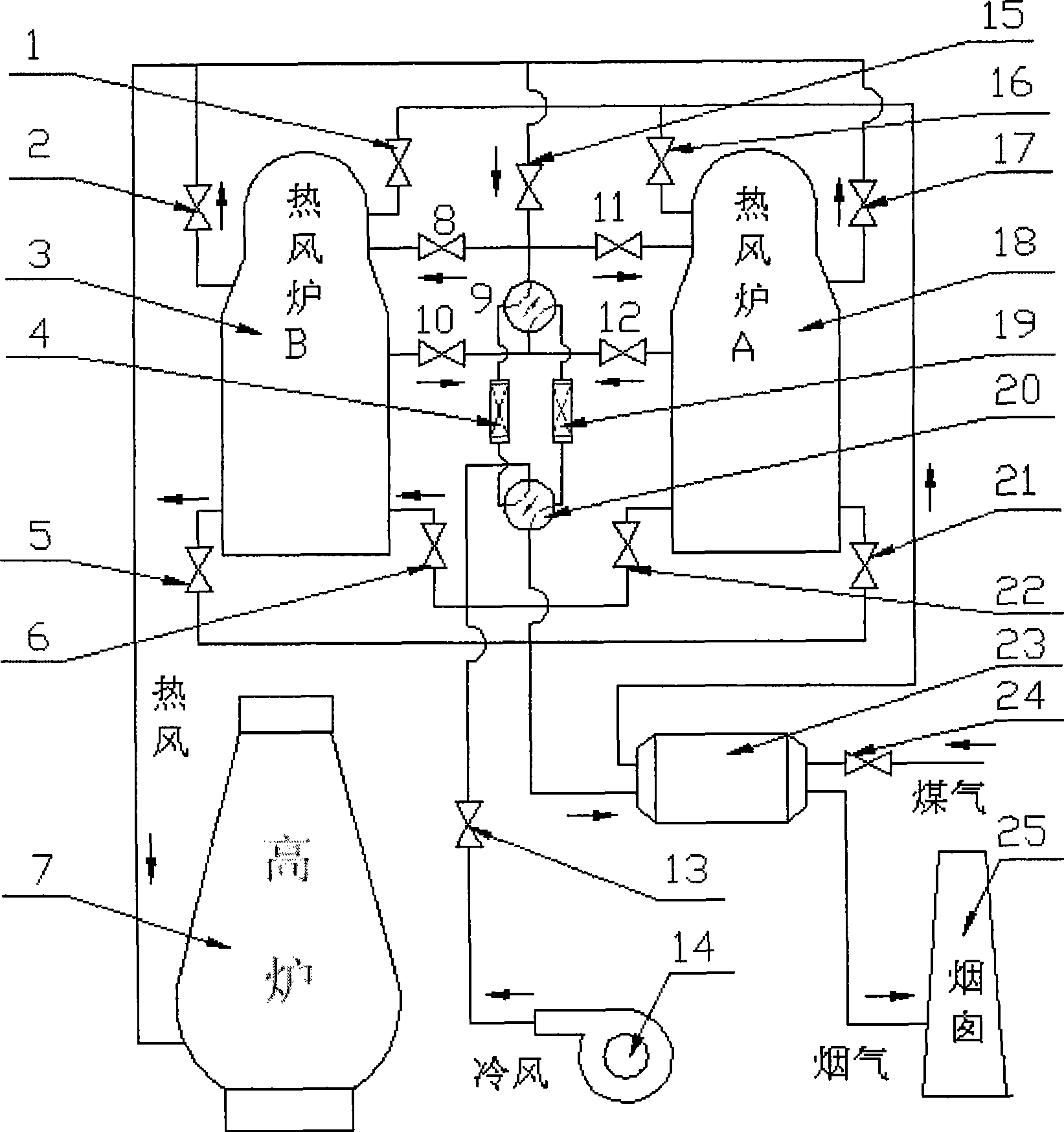

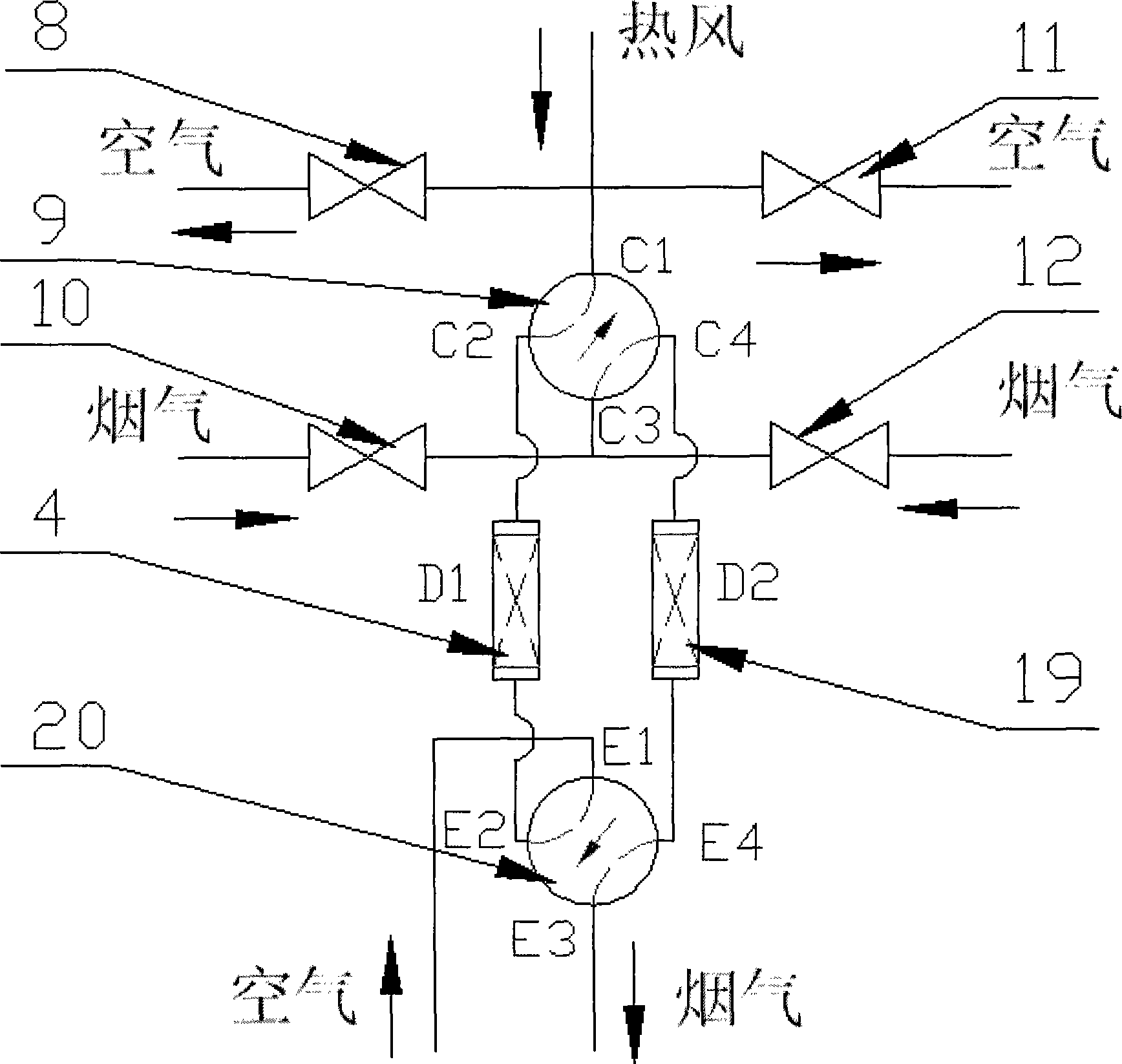

[0026] The specific embodiment of the high blast temperature system of the blast furnace hot blast stove of the present invention is as follows. figure 1 In the shown blast furnace hot blast stove high blast temperature system, two hot blast stoves are paired to work periodically, one is in the combustion period, the other is in the air supply period, the hot blast stove 3 is in combustion, and the hot blast stove 18 is in the air supply period. The coal gas enters the combustion chamber of the hot blast stove 3 through the gas valve 24 and is preheated by the separate heat pipe heat exchanger 23 through the gas valve 1. The flue gas valve 10 enters the ceramic regenerator pipe 19, and the flue gas at the end of the hot blast stove 3 passes through the flue gas valve 5 and the ceramic regenerator pipe 19 for heat exchange. After heating, the waste flue gas is discharged through the chimney 25. The cold air introduced by the fan 14 passes through the cold air valve 13, and 75-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com