Deep sludge dewatering technology

A deep dewatering and sludge dewatering technology, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of complex process, large operation volume, high energy consumption, improve corrosion resistance, avoid tilt, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

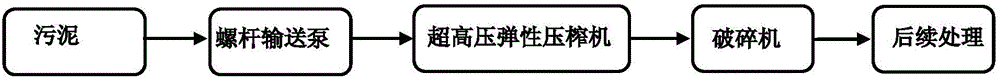

[0030] Such as figure 1 As shown, the present invention A sludge deep dehydration process , including the following steps:

[0031]1) The sludge with a moisture content of 82% produced after dehydration is transported to the ultra-high pressure elastic press by a screw type conveying pump; the pump outlet pressure of the screw conveying pump is 0.7-2MPa;

[0032] 2) The ultra-high pressure elastic press adopts the secondary pressing method to deeply dehydrate the sludge, so that the moisture content of the sludge is reduced to 53%; the pressing pressure of the ultra-high pressure elastic press is controlled at 3-7MPa, and the pressing feeding time is controlled at 20 -50mins, pressing time is 30-150mins;

[0033] 3) The sludge with a water content of 53% after deep dehydration is transported to the pulverizer by the conveyor, and the sludge is pulverized into powder or block;

[0034] 4) Transport the pulverized sludge to the boiler for incineration or make bricks and ot...

Embodiment 2

[0041] Such as figure 1 As shown, the present invention A sludge deep dehydration process , including the following steps:

[0042] 1) The sludge with a moisture content of 85% produced after dehydration is transported to an ultra-high pressure elastic press by a screw type conveying pump; the pump outlet pressure of the screw conveying pump is 0.7-2MPa;

[0043] 2) The ultra-high pressure elastic press adopts the secondary pressing method to deeply dehydrate the sludge, so that the moisture content of the sludge is reduced to 55%; the pressing pressure of the ultra-high pressure elastic press is controlled at 3-7MPa, and the pressing feeding time is controlled at 20 -50mins, the pressing time is 30-150mins; Wherein, used ultra-high pressure elastic press and filter plate thereof are identical with those described in embodiment 1;

[0044] 3) Transport the sludge with a water content of 55% after deep dehydration to the pulverizer by the conveyor, and pulverize the sludge...

Embodiment 3

[0047] Such as figure 1 As shown, the present invention A sludge deep dehydration process , including the following steps:

[0048] 1) The sludge with a water content of 75% produced after dehydration is transported to the ultra-high pressure elastic press by a screw type conveying pump; the pump outlet pressure of the screw conveying pump is 0.7-2MPa;

[0049] 2) The ultra-high pressure elastic press adopts the secondary pressing method to deeply dehydrate the sludge, so that the moisture content of the sludge is reduced to 50%; the pressing pressure of the ultra-high pressure elastic press is controlled at 3-7MPa, and the pressing feeding time is controlled at 20 -50mins, the pressing time is 30-150mins; Wherein, used ultra-high pressure elastic press and filter plate thereof are identical with those described in embodiment 1;

[0050] 3) The sludge with a water content of 50% after deep dehydration is transported to the pulverizer by the conveyor, and the sludge is pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com