a water purifier

A water purifier and water purification technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sewage treatment equipment, etc., can solve the problem of cost, land occupation or power consumption beyond the practical range, and increase the complexity of equipment , low degree of convenience and other problems, to achieve the effect of convenient use and maintenance, increase recovery rate, and no increase in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

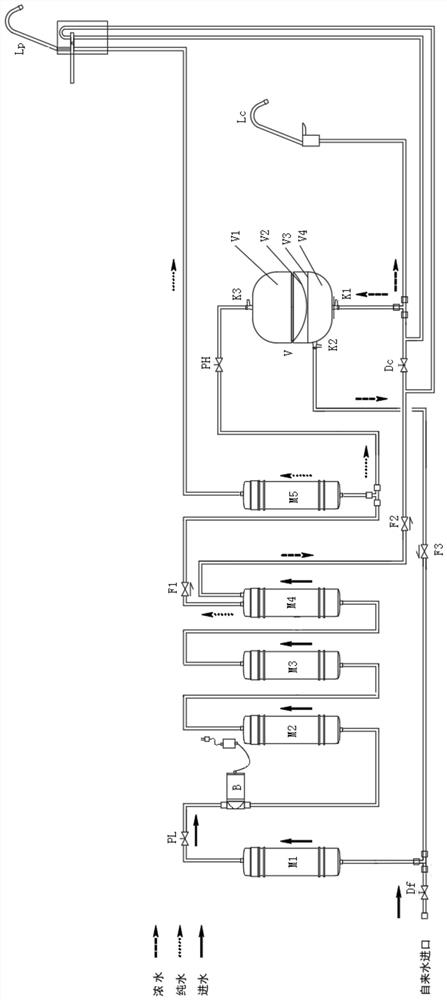

[0086] Embodiment 1 The water purifier of a kind of double-cavity storage tank of the present invention

[0087] The double-chamber water storage tank is specifically transformed from the pressure tank of the old water purifier:

[0088] refer to Figure 4 Shown in (4-1, 4-2), take the old type water purifier pressure tank, cut it in the middle, then add a porous partition, the air bag is separated at one end of the pressure tank. Then the barrel is welded on. In this way, the original airbag part becomes the clean water chamber V1, and the outer part of the airbag is the concentrated water chamber V4. Two holes are drilled in the concentrated water chamber V4, one of which is located at the bottom for the concentrated water inlet and outlet K1, and the other is located at the upper part for the concentrated water. The concentrated water return port K2 is only adjacent to the lower part of the partition plate V3.

[0089] A simplified technological process diagram of a no...

Embodiment 2

[0090] Embodiment 2 The water purification process of the water purifier of the present invention

[0091] Based on the water purifier provided in Example 1, the water purification steps are as follows:

[0092] Step 1: The measured tap water pressure is 0.5mpa; the pressure control range of the V4 low pressure switch in the concentrated water chamber is set to 0.1MPa (on) ~ 0.3MPa (off);

[0093] The pressure control range of the high-pressure switch of V1 in the water purification chamber is set to 0.2MPa (on) to 0.4MPa (off); plug in the power supply, and the water purifier starts to work.

[0094] Step 2: After the power is turned on, the low-voltage switch PL is turned on, and the tap water solenoid valve Df is opened, then the tap water passes through the tap water solenoid valve Df, and enters the purification membrane system (including the three-stage pre-treatment filter elements M1, M2, M3 through the booster pump B) After that, it enters the reverse osmosis membr...

Embodiment 3

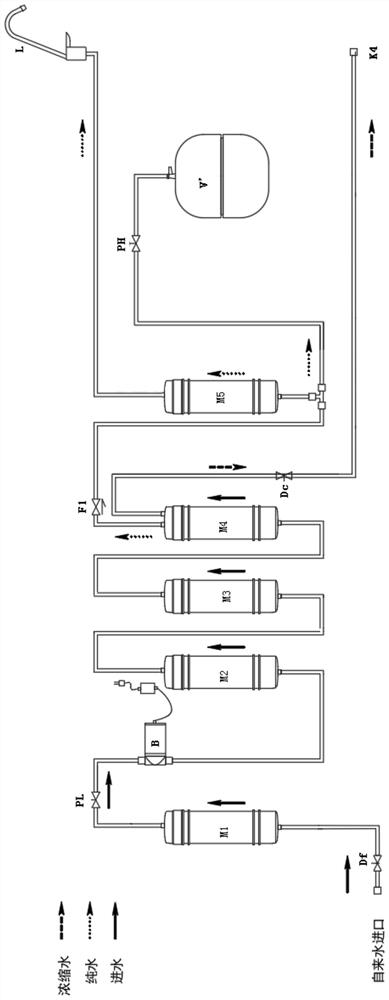

[0100] Embodiment 3 The transformation method of the double-barrel double-cavity water storage barrel of the present invention

[0101] Such as Figure 7 As shown in the structure diagram of the pressure barrel of the old water purifier, there is an air bag to achieve the function of providing the outlet pressure of the purified water.

[0102] Now two old water purifier pressure barrels are transformed, according to Figure 8 As shown in the modification, remove the gas check valve at the inlet of the air bag from the pressure tank, and use the gas pump port as the concentrated water connection port, and the pressure tank will be transformed into a clean water pressure tank. And another pressure barrel is installed with an outlet valve on the wall of the barrel, so that it becomes a concentrated water pressure tank, and the two tanks are pressed Figure 8 After connecting, a double-chamber pressure barrel has been prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com