Yellow rice wine brewing method for clean production

A rice wine brewing and clean production technology, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of difficult disposal and discharge, achieve the effect of improving operation intensity and working conditions, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

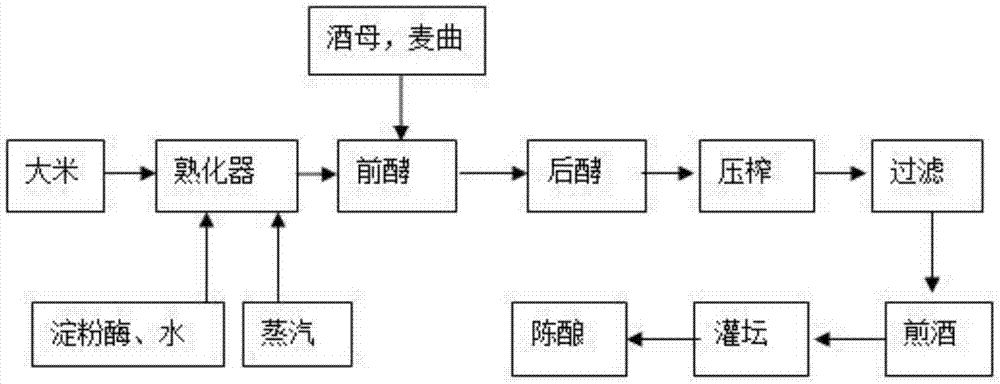

[0025] Such as figure 1 Shown a kind of yellow rice wine brewing method of clean production, this method comprises the following steps successively:

[0026] 1) Pour the rice into the entrance of the ripening device, add an appropriate amount of high-temperature amylase, the amount of high-temperature amylase added is 0.01 of the weight of the rice; then add brewing water at a weight ratio of rice:water=1:4;

[0027] 2) Turn on the steam in stages, keep the temperature of the feeding port of the slaking vessel at 95-100°C for 20 minutes, and obtain the mash, and then after the mash enters the post-ripening part, keep the temperature at 92-98°C; the gelatinization degree of the starch at the sampling port is qualified After that, it enters the cooling part and cools down to 26-30°C;

[0028] 3) Enter the front fermentation tank, add the cultivated distiller's yeast in advance in the front fermentation tank, and the distiller's yeast is 10% of the weight of rice; %, the fermen...

Embodiment 2

[0033] Such as figure 1 Shown a kind of yellow rice wine brewing method of clean production, this method comprises the following steps successively:

[0034] 1) Pour the rice into the entrance of the ripening device, add an appropriate amount of high-temperature amylase, the amount of high-temperature amylase added is 0.01 of the weight of the rice; then add brewing water at a weight ratio of rice:water=1:4;

[0035] 2) Turn on the steam in stages, keep the temperature of the feeding port of the slaking vessel at 95-100°C for 20 minutes, and obtain the mash, and then after the mash enters the post-ripening part, keep the temperature at 92-98°C; the gelatinization degree of the starch at the sampling port is qualified After that, it enters the cooling part and cools down to 26-30°C;

[0036] 3) Enter the front fermentation tank, add the cultured distiller's yeast in advance in the front fermentation tank, and the distiller's yeast is 12% of the rice weight; %, the fermentatio...

Embodiment 3

[0041] Such as figure 1 Shown a kind of yellow rice wine brewing method of clean production, this method comprises the following steps successively:

[0042] 1) Pour the rice into the entrance of the ripening device, add an appropriate amount of high-temperature amylase, the amount of high-temperature amylase added is 0.01 of the weight of the rice; then add brewing water at a weight ratio of rice:water=1:4;

[0043] 2) Turn on the steam in stages, keep the temperature of the feeding port of the slaking vessel at 95-100°C for 20 minutes, and obtain the mash, and then after the mash enters the post-ripening part, keep the temperature at 92-98°C; the gelatinization degree of the starch at the sampling port is qualified After that, it enters the cooling part and cools down to 26-30°C;

[0044] 3) Enter the front fermentation tank, add the cultured distiller's yeast in advance in the front fermentation tank, and the distiller's yeast is 8% of the rice weight; %, the fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com