Heat treatment process for large-scale pump cases

A technology for heat treatment furnaces and pump casings, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of difficult to find quenching and tempering units, high cost, large size, etc., to save heat preservation time, avoid processing, and save heat treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

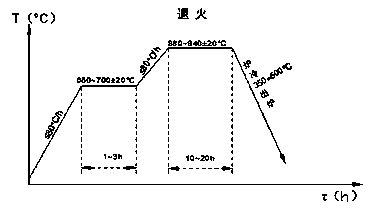

[0026] The large-scale pump casing formed by casting according to the internal control chemical composition is cleaned and sanded, then put into a large-scale heat treatment furnace for annealing treatment, heated to 650°C at a heating rate of 70°C / h and kept for 1 hour, and then heated at a rate of 70°C / h Heat at a speed of 880°C for 10 hours, then cool the furnace to 350°C and pull out the cutting riser with temperature, the cutting temperature is 200°C;

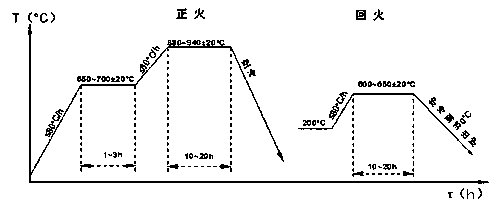

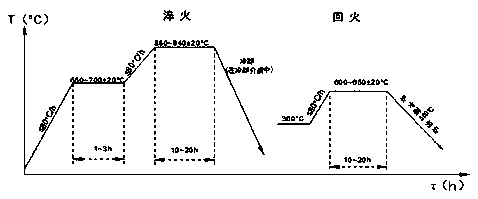

[0027] (2) After cutting the riser, put it back into the heat treatment furnace for normalizing process, then heat it to 700°C at a heating rate of 60°C / h and keep it for 2 hours, and then heat it to 890°C at a heating rate of 70°C / h Keep warm at ℃ for 12 hours, then take it out of the oven and blow it with strong wind and spray (fog quenching);

[0028] (3) Finally, pull the pump casing into the heat treatment furnace for tempering process, heat it to 660°C at a heating rate of 60°C / h and keep it for 10 hours, then cool i...

Embodiment 2

[0030] (1) Clean the large-scale pump casing formed according to the internal control chemical composition, clean the sand, put it into a large-scale heat treatment furnace for annealing treatment, heat it to 690°C at a heating rate of 72°C / h for 2 hours, and then heat it at 72°C / h The heating rate of h is heated to 890°C for 15 hours, and then the furnace is cooled to 400°C to pull out the cutting riser with temperature, and the cutting temperature is 220°C;

[0031] (2) After cutting the riser, put it back into the heat treatment furnace for normalizing process, then heat it to 710°C at a heating rate of 65°C / h and keep it for 3 hours, and then heat it to 950°C at a heating rate of 72°C / h Keep warm at ℃ for 20 hours, then take out the furnace and blow strong wind and spray (fog quenching);

[0032] (3) Finally, pull the pump casing into the heat treatment furnace for tempering process, heat it to 620°C at a heating rate of 67°C / h and keep it for 15 hours, then cool it to 500...

Embodiment 3

[0034] (1) Clean the large-scale pump casing formed by casting according to the internal control chemical composition, clean the sand, put it into a large-scale heat treatment furnace for annealing treatment, heat it to 720°C at a heating rate of 80°C / h for 3 hours, and then heat it at 80°C / h The heating rate of h is heated to 950°C for 10 hours, and then the furnace is cooled to 500°C to pull out the cutting riser with temperature, and the cutting temperature is 230°C;

[0035] (2) After cutting the riser, put it back into the heat treatment furnace for normalizing process, then heat it to 650°C at a heating rate of 80°C / h and keep it for 3 hours, and then heat it to 880°C at a heating rate of 80°C / h Keep warm at ℃ for 15 hours, then take it out of the furnace and blow it with strong wind and spray (fog quenching);

[0036] (3) Finally, pull the pump casing into the heat treatment furnace for tempering process, heat it to 610°C at a heating rate of 80°C / h and keep it for 20 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com