Modified blue-green algae biochar composite and application thereof to treatment of electroplating wastewater

A technology for composite materials and electroplating wastewater, which is applied in special compound water treatment, water/sewage treatment, metallurgical wastewater treatment, etc., and can solve problems such as odorous anaerobic sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

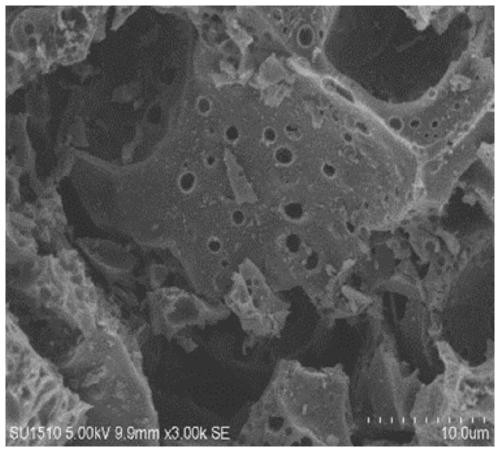

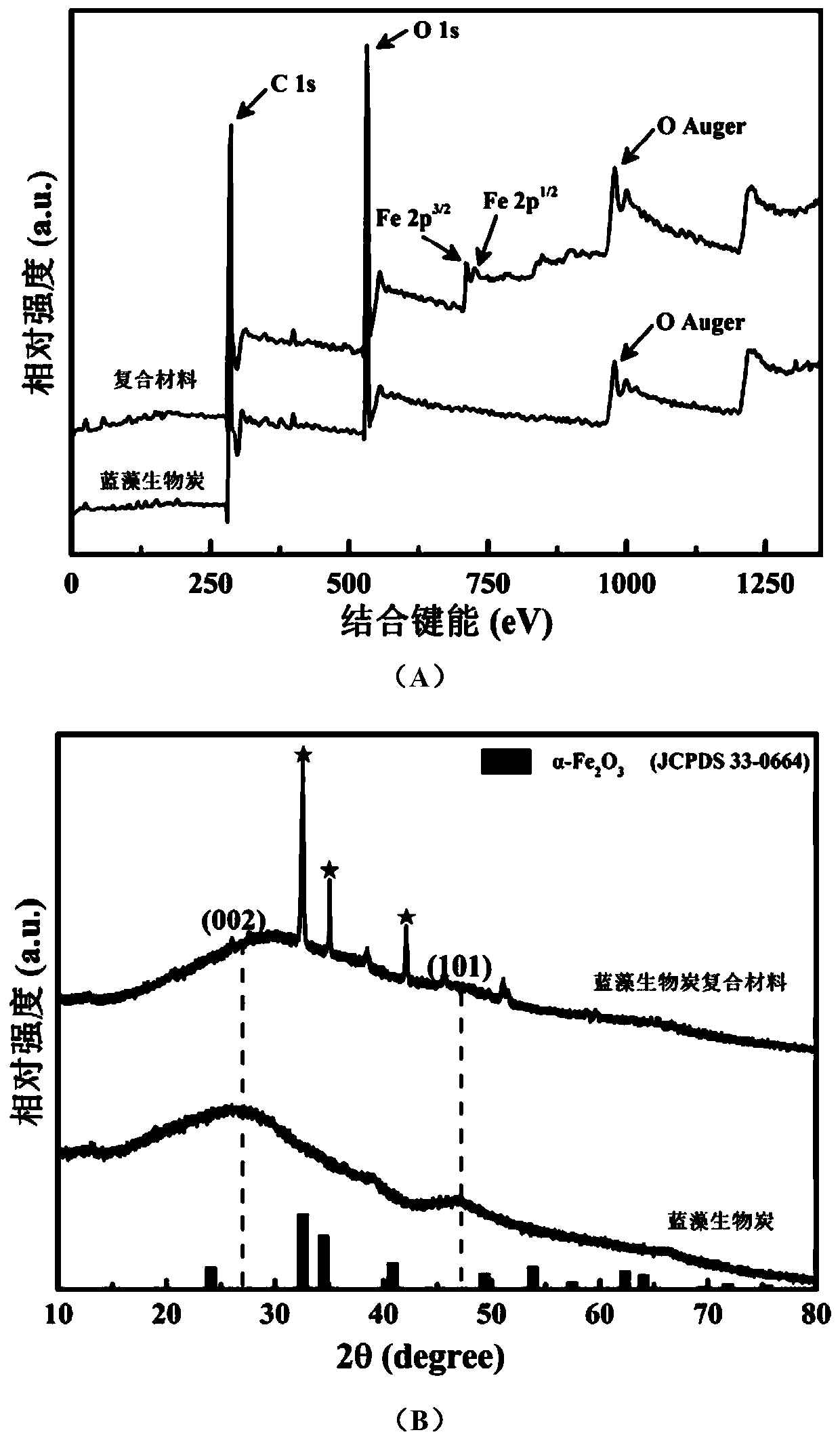

[0041] Embodiment 1 Preparation of modified cyanobacteria biochar without loading iron

[0042] A preparation method of modified cyanobacteria biochar, comprising the following steps:

[0043] (1) Place Taihu Lake cyanobacteria in an oven at 105°C for 24 hours, grind and pass through an 80-mesh sieve after drying, then take the sieved sample and mix it with potassium hydroxide. The mass ratio of the sample to potassium hydroxide is 1: 1;

[0044] (2) Under the protection of nitrogen with a gas flow rate of 80sscm, thermally crack the mixed sample. The thermal cracking process is divided into two stages. First, the temperature is raised to 400°C at 5°C / min, and then thermally cracked at 400°C for 90min. Then, the temperature was raised to 800°C at a rate of 10°C / min, and kept at 800°C for 2 hours;

[0045] (3) Put the pyrolyzed sample in a mortar, grind it, pass through a 100-mesh sieve, then pickle it in 1mol / L hydrochloric acid, wash it with water until neutral, put it in a...

Embodiment 2

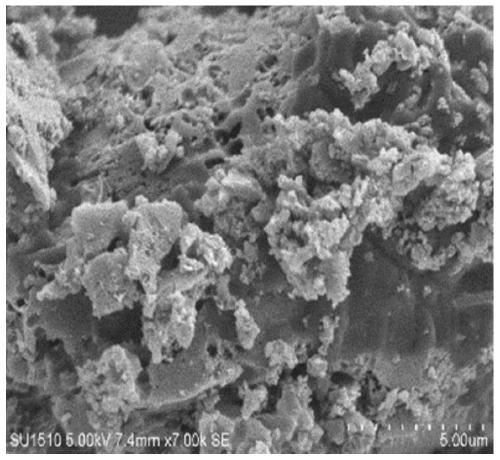

[0047] The preparation of the modified cyanobacteria biochar composite material of embodiment 2 loaded iron

[0048] A preparation method of modified cyanobacteria biochar composite material, comprising the following steps:

[0049] (1) Dry the Taihu cyanobacteria in an oven at 105°C for 24 hours, grind them after drying, and pass through an 80-mesh sieve. Then get the sample after sieving and mix with potassium hydroxide, the mass ratio of sample and potassium hydroxide is 1:1;

[0050] (2) Under the protection of nitrogen with a gas flow rate of 80sscm, the mixed sample is pyrolyzed. The pyrolysis process is divided into two stages. First, the temperature is raised to 400°C at 5°C / min, and pyrolyzed at 400°C for 90min. , and then heated up to 800°C at a rate of 10°C / min, and kept at 800°C for 2 hours;

[0051] (3) Put the pyrolyzed sample in a mortar, grind it, pass it through a 100-mesh sieve, pickle it in 1mol / L hydrochloric acid, wash it with water until pH=7, put it in...

Embodiment 3

[0055] The processing example of embodiment 3 electroplating waste water

[0056] The materials obtained in the above-mentioned Example 1 and Example 2 were used to treat zinc-nickel alloy electroplating wastewater. The parameters of electroplating wastewater are shown in Table 2.

[0057] The specific treatment process is as follows: First, adjust the initial pH value of the electroplating wastewater to 6, then add 0.5 g of modified cyanobacteria biochar or modified cyanobacteria biochar composite material, and after 20 minutes to reach adsorption equilibrium, add 30 mmol of hydrogen peroxide for Fenton-like oxidation After the reaction (about 60min), sodium hydroxide was added for precipitation, and the supernatant was filtered through a 0.45 μm filter head, and the nickel ion concentration was determined by flame atomic absorption method, and the modified cyanobacteria biochar composite material was desorbed and cleaned. for reuse. The calculation formula of nickel remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com