High-efficiency electroplating wastewater treatment and resource utilization device

A high-efficiency technology for electroplating wastewater, applied in metallurgical wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low operating cost, reduced treatment effect, small footprint, etc., and achieve the elimination of poisonous hazards , to avoid the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

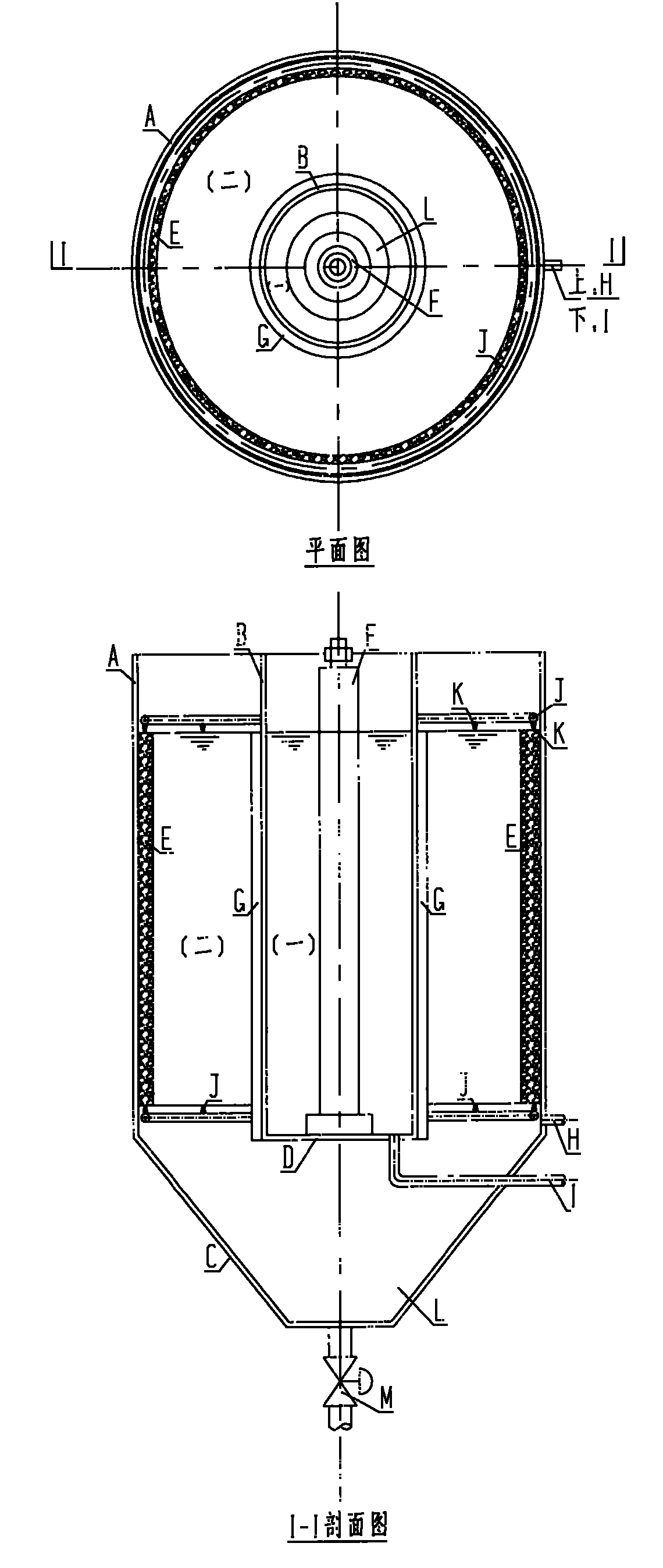

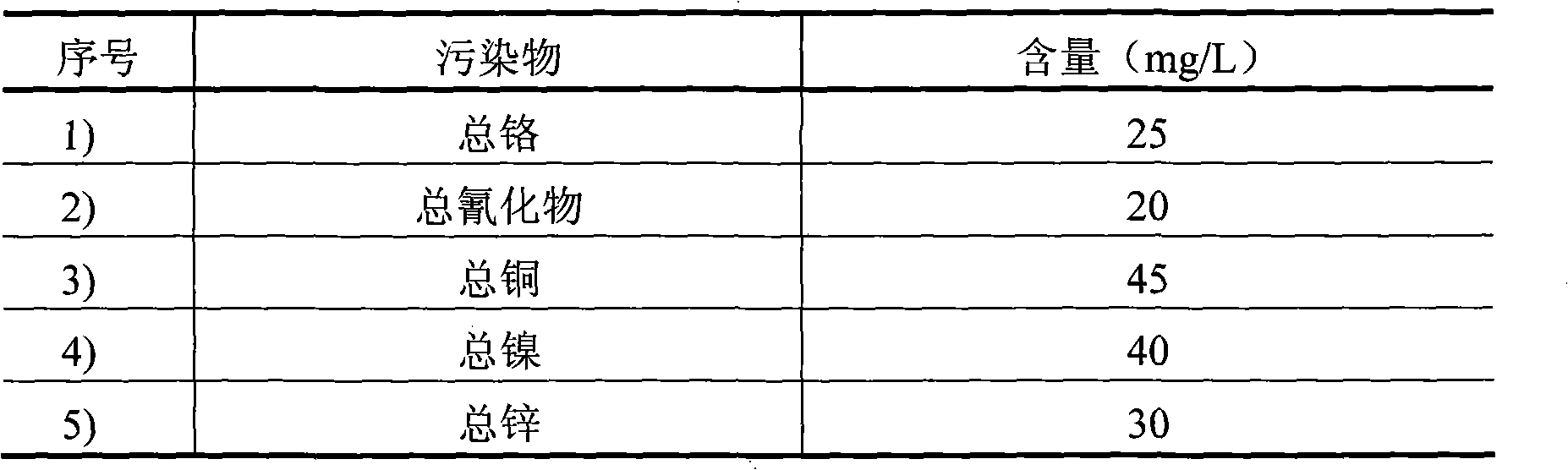

Embodiment 1

[0025] The plating types of a hardware and plastic electroplating factory include nickel, copper, zinc, chromium, gold, and silver. Waste water containing gold and silver has been recovered separately by each workshop, and the discharged waste water mainly includes ions containing nickel, copper, zinc, chromium, and cyanide. Since hexavalent chromium cannot directly enter the recovery system, it needs to be pretreated, adding acid and reducing agent to control a certain PH value and ORP value, stirring and reacting completely before entering the recovery system together with other waste water. In addition, waste water containing oil and impurities must first be treated by grilles and oil and slag separation tanks before entering the recovery system. Discharge the pretreated wastewater into the regulating tank (with a water capacity of about 30m 3 ). The pH value of the wastewater is adjusted to a range conducive to efficient recovery of nickel. The concentration of pollutan...

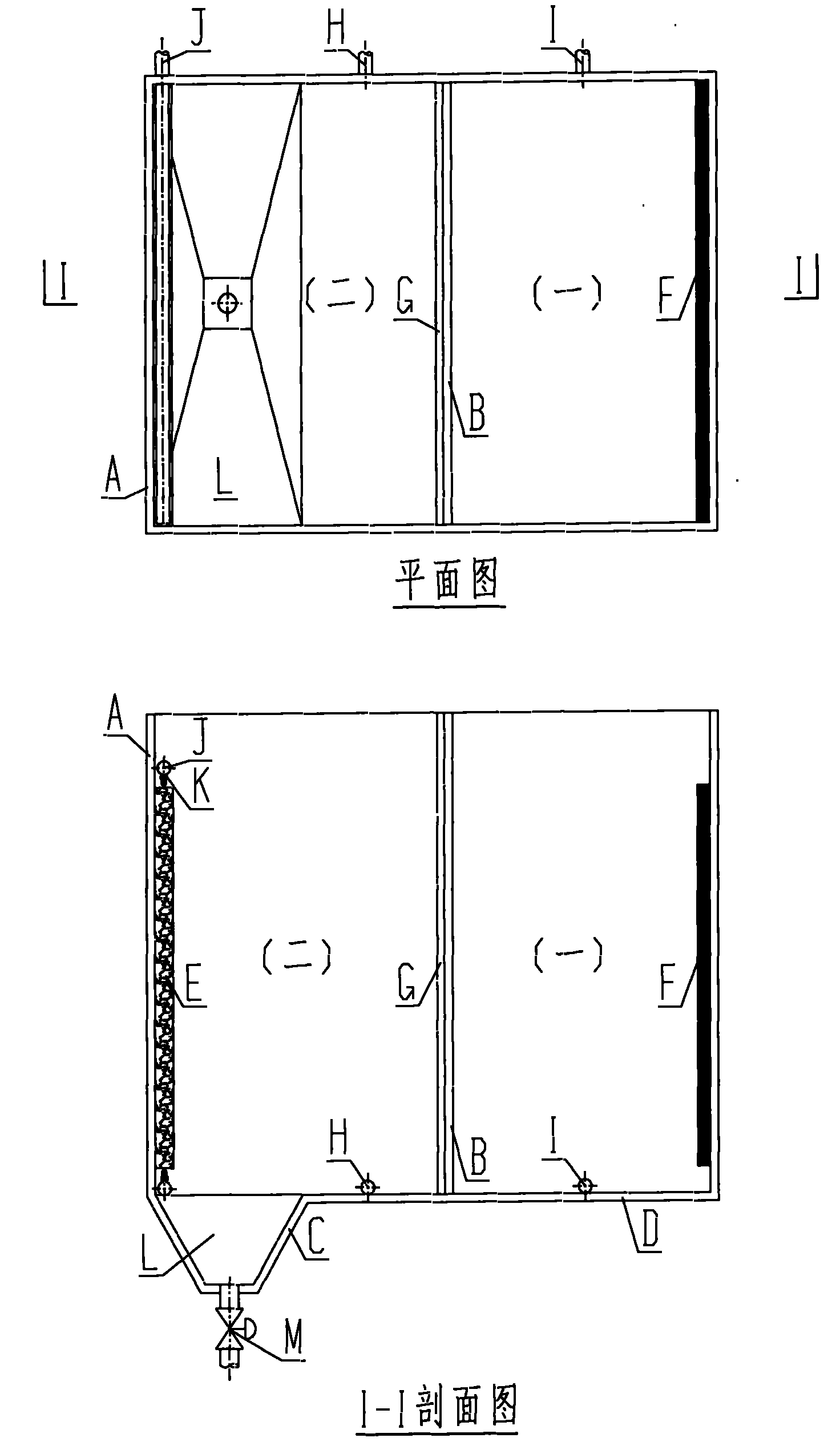

Embodiment 2

[0032] The copper plating tank of an electroplating factory produces electroplating waste liquid, mainly copper sulfate and sulfuric acid, with a copper ion concentration of 748mg / L. Will be about 2.6m 3 The electroplating waste liquid is pumped into the high-efficiency metal and acid anion recovery device for electrolytic recovery. After recycling, 1940g of copper powder was collected in the collection tank of the cathode chamber. 6L of sulfuric acid with a concentration of about 50% was recovered from the anode chamber. The cathode water from which metal ions have been removed can be reused as rinse water.

Embodiment 3

[0034] An electroplating factory does aluminum surface treatment, and the treatment solution is sulfuric acid, phosphoric acid, and nitric acid. After the treatment solution is used for a period of time, the surface treatment effect is affected due to the accumulation of excessive aluminum ions. will be about 3m 3 This kind of waste liquid is pumped into the high-efficiency metal and acid ion recovery device for recovery and treatment. The mixed acid solution recovered in the anode chamber is about 7L, wherein the concentration of sulfuric acid is about 10%, the concentration of nitric acid is about 15%, and the concentration of phosphoric acid is about 60%. Since the chemical composition of the recovered mixed acid is similar to that of the original treatment solution, it can be sent back to the production link for use after a little adjustment. Aluminum is transformed into aluminum hydroxide flocs in the cathode chamber. The latter becomes a mud cake after flocculation, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com