Electroplating wastewater treating and recycling process and system

A technology of electroplating wastewater and process, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of affecting the recovery efficiency of the membrane system and increasing the treatment cost, so as to reduce chemical pollution. Generation of sludge, improvement of recovery rate, and improvement of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

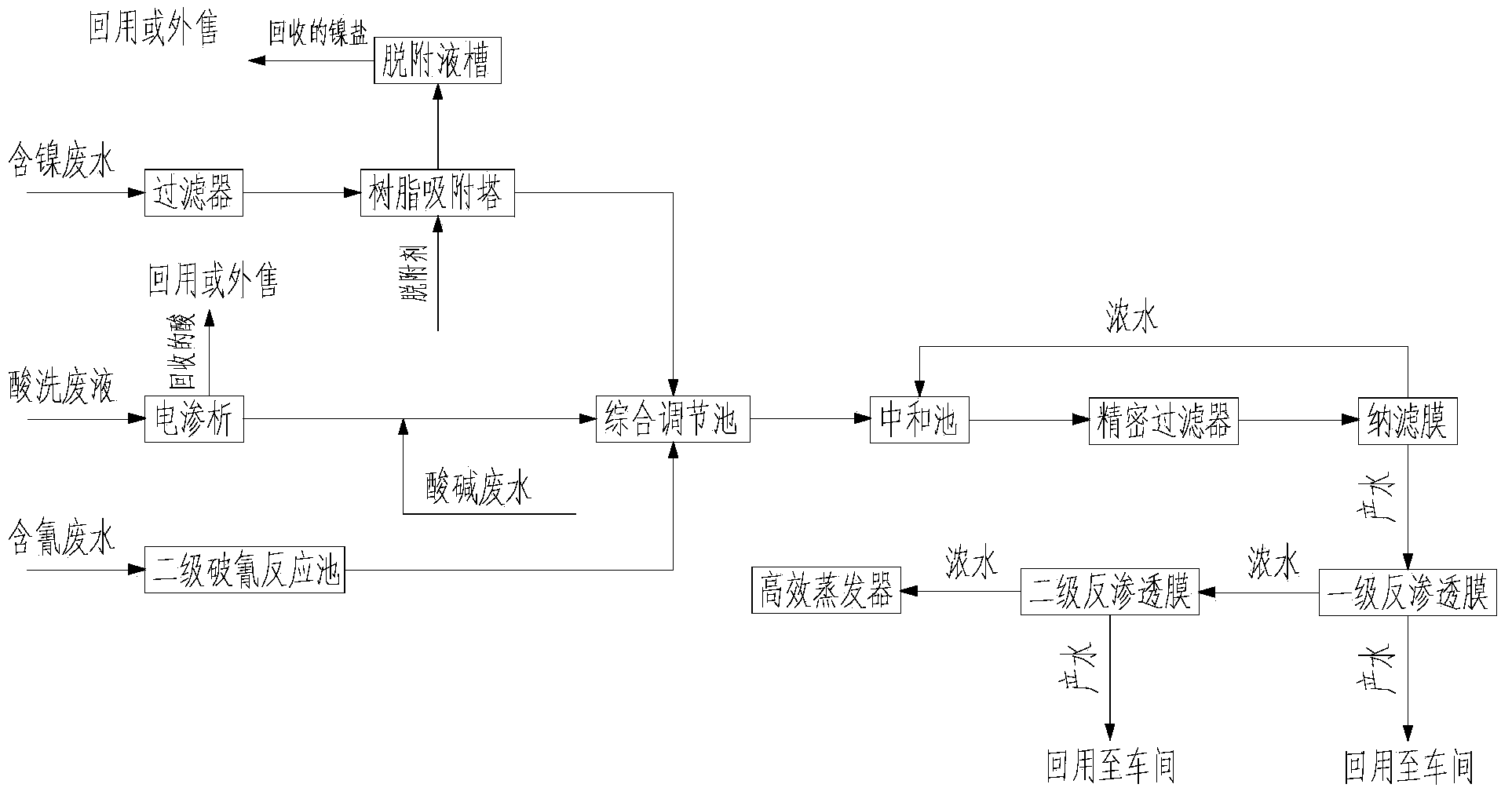

[0059] The wastewater discharged by a certain electroplating factory in this example is as follows: nickel-containing wastewater: 100t / d, pickling waste liquid: 1t / d, acid-base wastewater 50t / d, and cyanide-containing wastewater 80t / d.

[0060] The electroplating comprehensive wastewater treatment and recycling method of the present example comprises the following steps:

[0061] 1) After the 100t / d nickel-containing wastewater is collected, it is pumped to the activated carbon filter to remove larger suspended particles in the raw water, and then enters the resin adsorption tower filled with 2m3D113 at a flow rate of 4BV / h, and the adsorbed water enters the Comprehensive regulating pool. When the Ni2+ of the effluent is >0.5mg / L set value, use 2BV of 2% sulfuric acid solution for regeneration, and the obtained nickel sulfate regeneration solution is reused in the electroplating workshop, and rinsed with 2BV of clean water after regeneration.

[0062] 2) After the 1t / d pickli...

Embodiment 2

[0070] The wastewater discharged by a certain electroplating factory in this example is as follows: nickel-containing wastewater: 200t / d, pickling waste liquid: 1.5t / d, acid-base wastewater 80t / d, and cyanide-containing wastewater 100t / d.

[0071] The electroplating comprehensive wastewater treatment and recycling method of the present example comprises the following steps:

[0072] 1) After the 200t / d nickel-containing wastewater is collected, it is pumped to an activated carbon filter to remove larger suspended particles in the raw water, and then enters a resin adsorption tower filled with 3m3CH-90 at a flow rate of 6BV / h. The effluent enters the comprehensive regulating pool. When the Ni2+ of the effluent is >0.5mg / L set value, use 2BV of 4% sulfuric acid solution for regeneration, and the obtained nickel sulfate regeneration solution is reused in the electroplating workshop, and rinsed with 2BV of clean water after regeneration.

[0073] 2) After the 1.5t / d pickling wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com