Method for preparing catalyst by using electrolysis waste water and electrolysis sludge

A technology for electroplating wastewater and electroplating sludge, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve environmental pollution, many factories, small scale, etc. problems, to achieve the effect of alleviating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

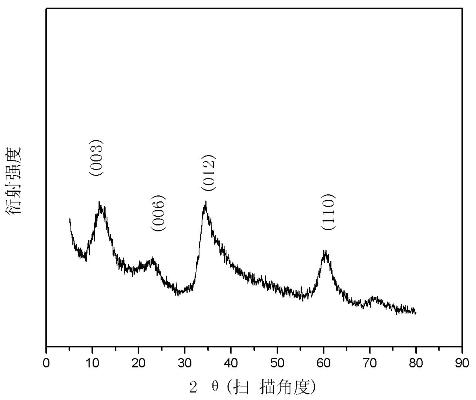

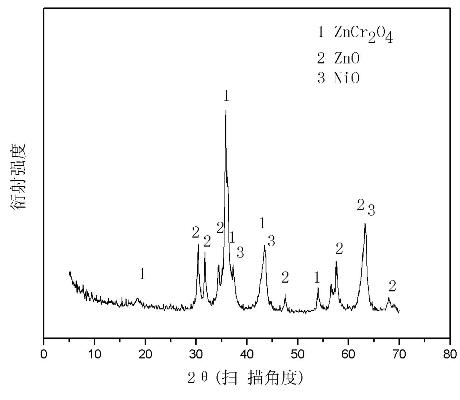

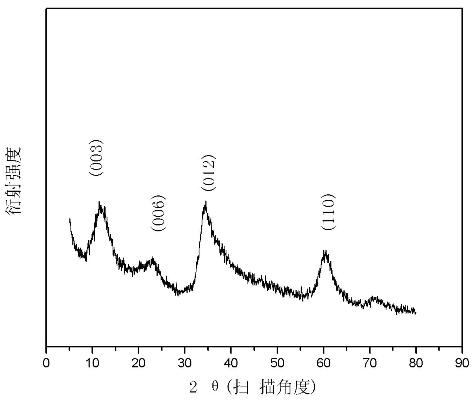

Image

Examples

Embodiment

[0023] The process and steps of this embodiment are as follows:

[0024] (1) Use industrial waste electroplating wastewater and sludge for pretreatment.

[0025] The main heavy metal content (mg / L) in electroplating wastewater is shown in Table 1 below:

[0026] Table 1 Contents of main heavy metals in electroplating wastewater (mg / L)

[0027] element

Ni

Zn

Cr

Cu

Fe

Co

Ca

Al

mg / L

2300.4

3200.6

946.8

3.4

9.7

3.4

18.7

8.9

[0028] The main heavy metal content (wt%) in the electroplating sludge is shown in Table 2 below:

[0029] Table 2 Contents of main heavy metals in electroplating sludge (wt%)

[0030] element

Ni

Zn

Cr

Cu

Fe

Co

Ca

Al

g / 100g dry sludge

4.8

6.5

3.5

0.6

50.4

0.2

23.4

1.7

[0031] (2) Mix the above-mentioned electroplating wastewater and electroplating sludge according to a certain ratio: per gram of dry ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com