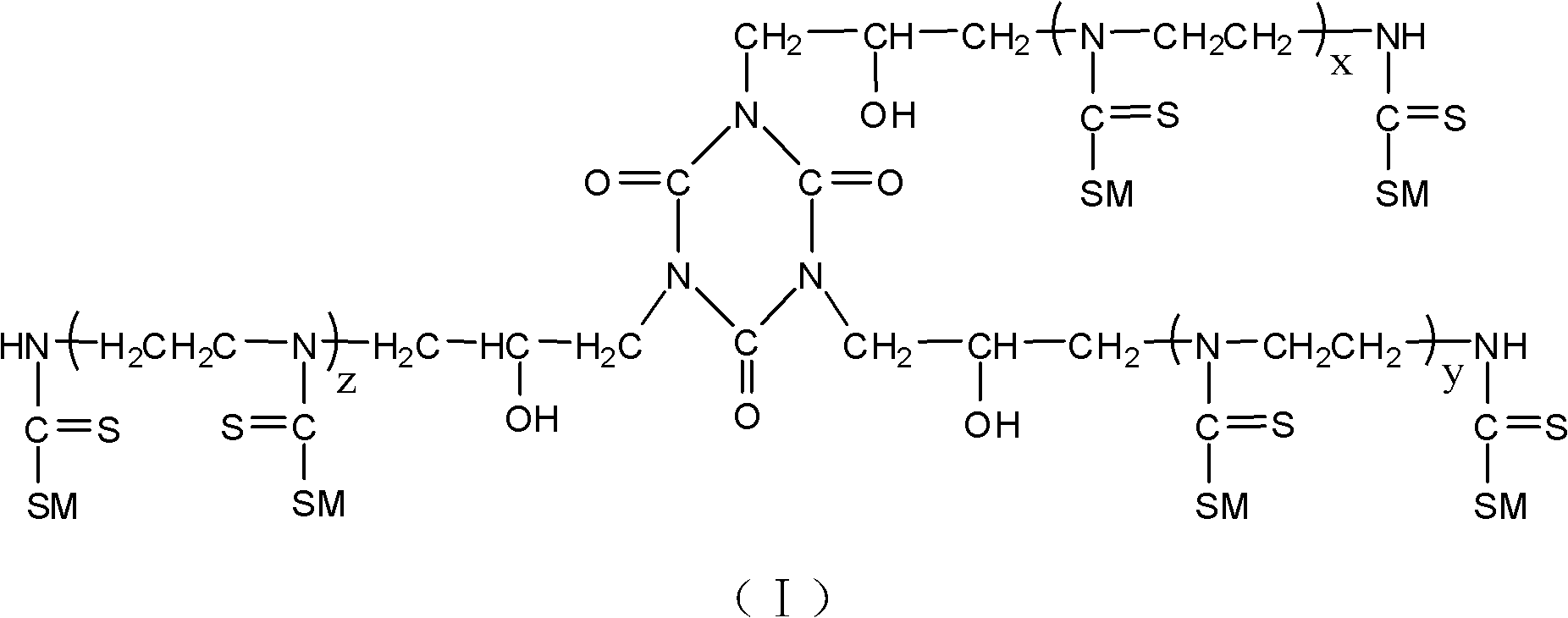

Cyanuric acid-based heavy metal chelating flocculant and preparation method thereof

A cyanuric acid-based, heavy metal technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of difficult discharge of heavy metal ions, poor sedimentation performance, large steric hindrance, etc., and achieves easy promotion, poor sedimentation performance, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

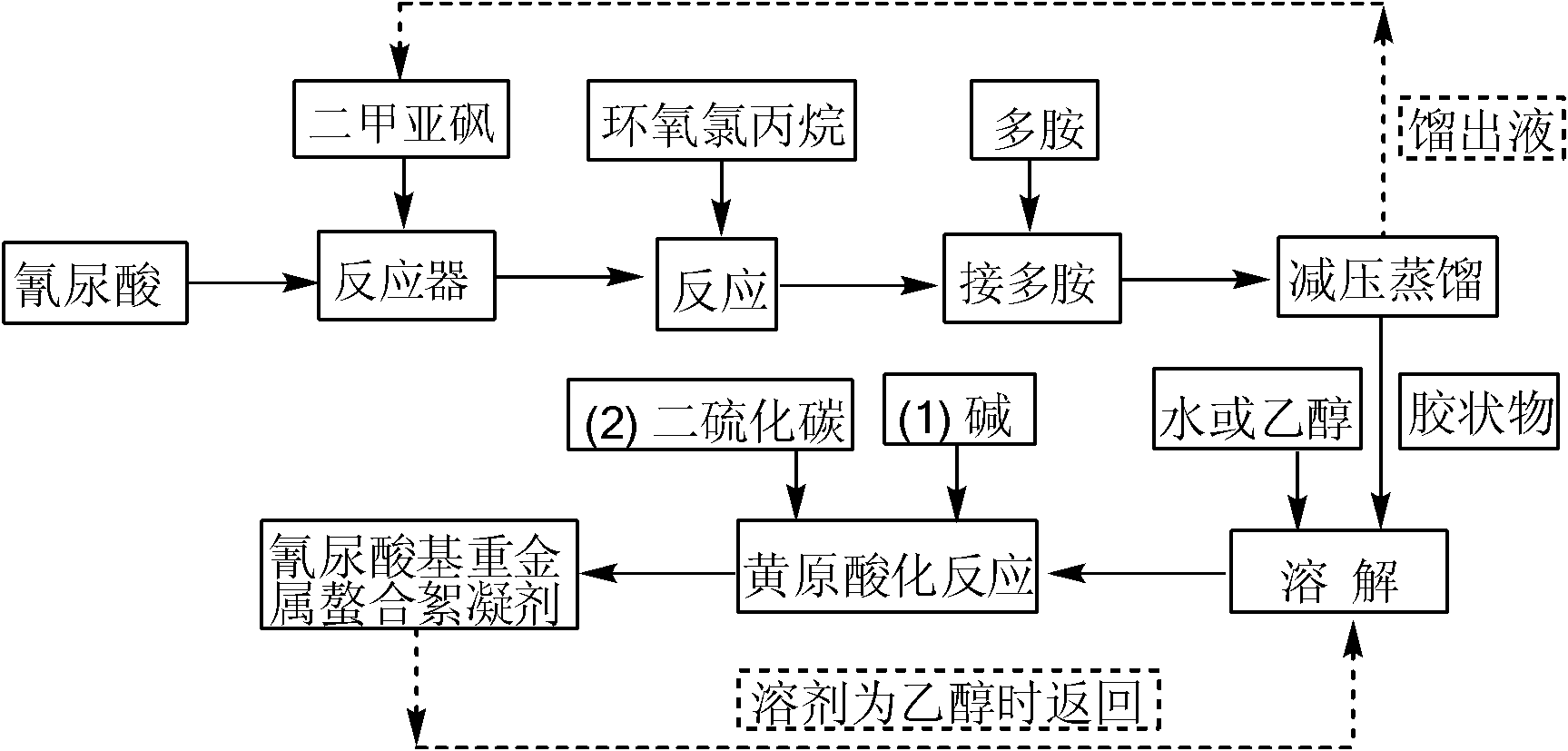

Method used

Image

Examples

Embodiment 1

[0032] (1) Dissolve 50g cyanuric acid in 2.2L dimethyl sulfoxide to form a solution with a concentration of 2.0% by mass, add it to a 5L reactor with mechanical stirring and reflux condenser, and mix cyanuric acid and epoxy The molar ratio of chloropropane was 1:3.0, and 91mL of epichlorohydrin was slowly added dropwise, the temperature was controlled at 80°C, and the reaction was carried out for 8h.

[0033] (2) According to the molar ratio of epichlorohydrin to triethylenetetramine of 1:1.0, 171.3 mL of triethylenetetramine was slowly added dropwise, and reacted at 60° C. for 5 hours.

[0034] (3) The above reaction mixture is distilled under reduced pressure at 1 mmHg, and the solvent dimethyl sulfoxide is evaporated to obtain a colorless gum, and the dimethyl sulfoxide is collected as a solvent for the next round of reaction;

[0035](4) Add 3.71L of dehydrated ethanol to the jelly obtained in the previous step to form a solution with a mass percent concentration of 10%, a...

Embodiment 2

[0038] (1) 50g cyanuric acid is dissolved in the dimethyl sulfoxide that reclaims in embodiment 1 step (3), is made into the solution that mass percent concentration is 3.5%, joins the reaction that has mechanical stirring and reflux condenser in 5L In the container, according to the molar ratio of cyanuric acid and epichlorohydrin as 1:3.1, slowly add epichlorohydrin 94.2mL dropwise, control the temperature at 90°C, and react for 6h;

[0039] (2) Slowly add 185.9 mL of triethylenetetramine dropwise at a molar ratio of epichlorohydrin to triethylenetetramine of 1:1.05, and react at 70° C. for 5 hours;

[0040] (3) The above reaction mixture is distilled under reduced pressure at 1 mmHg, and the solvent dimethyl sulfoxide is evaporated to obtain a colorless gum, and the dimethyl sulfoxide is collected as a solvent for the next round of reaction;

[0041] (4) The gel obtained in the previous step is added to the solvent separated in Example 1 step (4) and the ethanol for washing...

Embodiment 3

[0044] (1) 50g cyanuric acid is dissolved in the dimethyl sulfoxide that reclaims in embodiment 2 step (3), is made into the solution that mass percent concentration is 5%, joins the reaction that has mechanical stirring and reflux condenser in 5L In the container, according to the molar ratio of cyanuric acid and epichlorohydrin as 1:3.2, slowly add epichlorohydrin 97.2mL dropwise, control the temperature at 70°C, and react for 8h;

[0045] (2) Slowly add 201.0 mL of triethylenetetramine dropwise at a molar ratio of 1:1.1 between epichlorohydrin and triethylenetetramine, and react at 80° C. for 4 hours;

[0046] (3) The above reaction mixture is distilled under reduced pressure at 1 mmHg, and the solvent dimethyl sulfoxide is evaporated to obtain a light yellow gum, and the dimethyl sulfoxide is collected as a solvent for the next round of reaction;

[0047] (4) The gel obtained in the previous step is added to the solvent separated in Example 2 step (4) and the ethanol for w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com