Method for treating nickel/copper-containing electroplating wastewater by using weak acid ion exchange fibers

An ion-exchange fiber and ion-exchange technology, applied in the field of electroplating wastewater treatment, can solve problems such as differences, small amount of treated wastewater, and single metal ion components, and achieve high efficiency, fast desorption rate, and large adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] b. Pretreatment of weak acid ion exchange fibers: 2g of weak acid ion exchange fibers (the weak acid ion exchange fibers are ion exchange fibers prepared according to the technical scheme of Patent No. 200410060275.0) are wet loaded into Φ10×300mm ion exchange columns, and then Use sodium hydroxide solution with a concentration of 1mol / L to wash and transform the ion exchange fiber in the column through the ion exchange column (the rate of sodium hydroxide solution passing through the column during the washing process is 1ml / (min·g)), and the ion exchange The fibers are all converted into Na-type ion exchange fibers (at this time, the pH of the effluent from the ion exchange column is >10); then the column is washed with deionized water until neutral, and the treated ion exchange column equipped with ion exchange fibers is obtained;

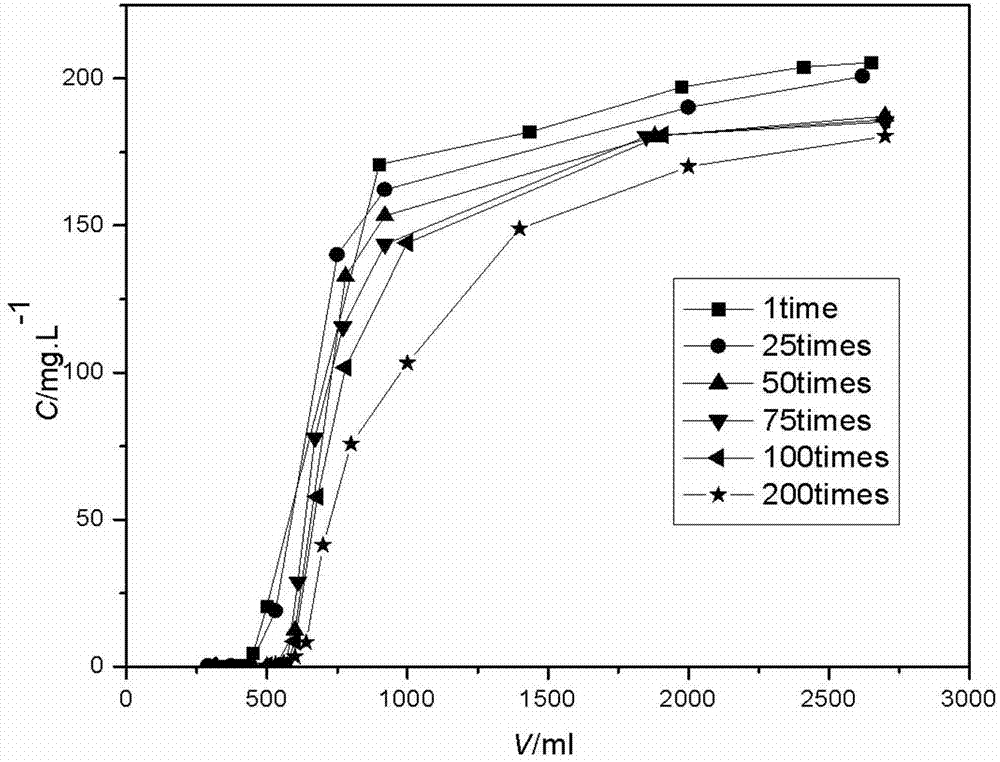

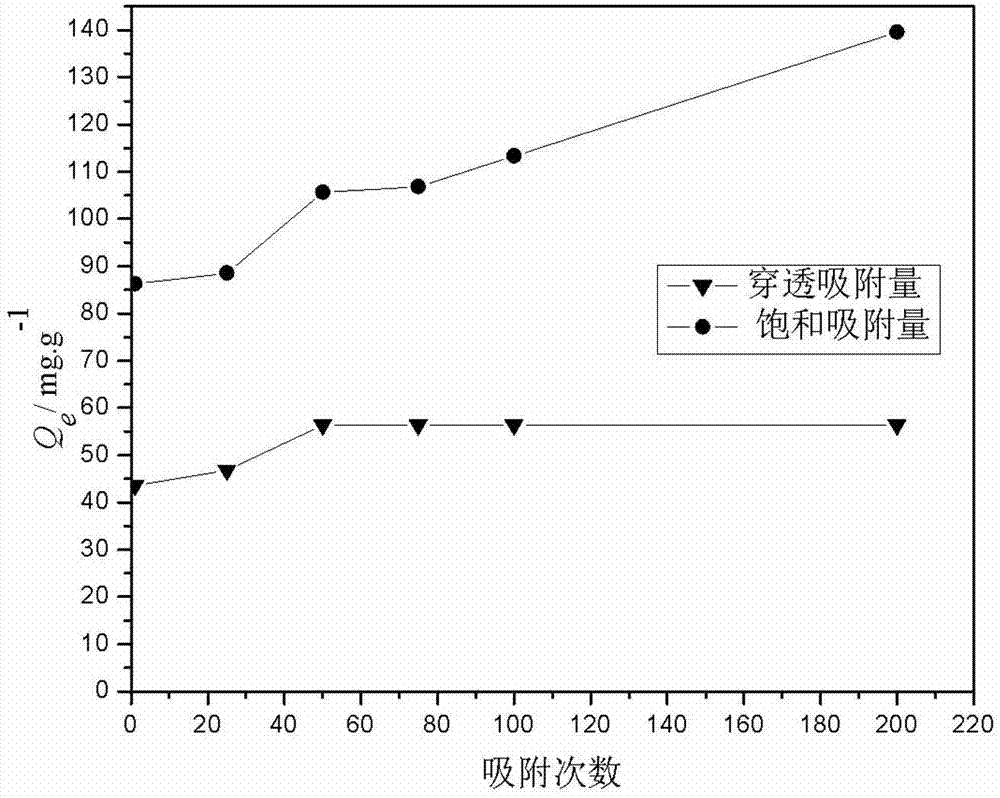

[0034] c, the electroplating waste water after the pretreatment of step a is passed into the ion exchange column that the ion exchange fib...

Embodiment 2

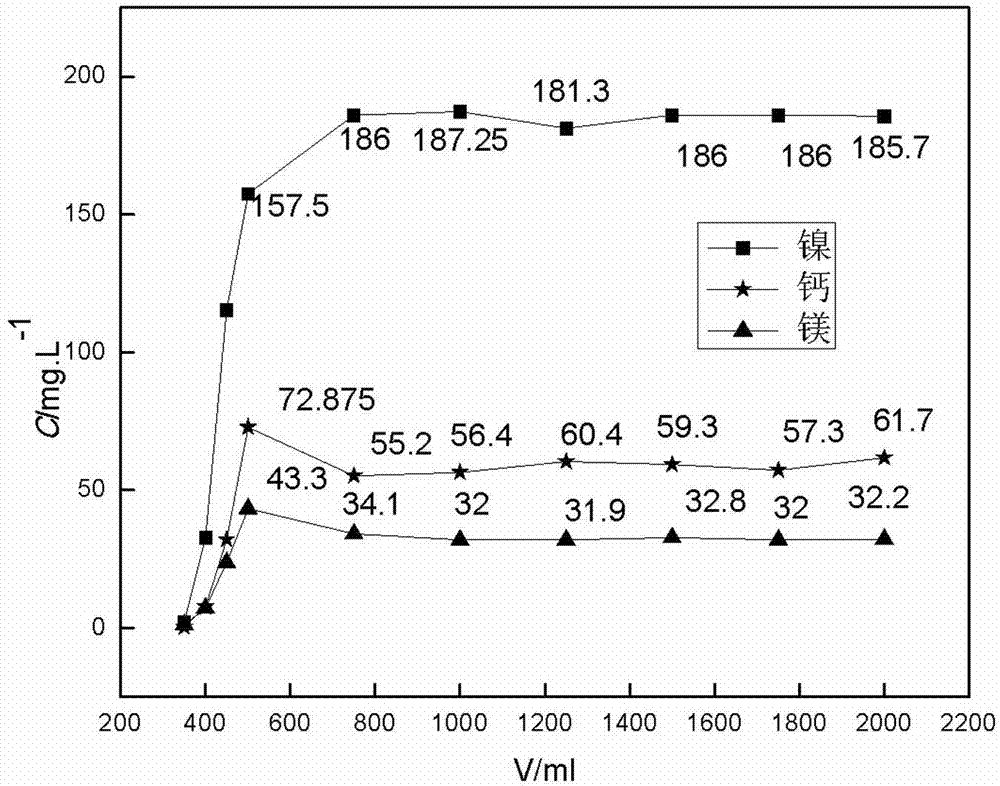

[0043] The concentration of nickel in the original nickel-containing electroplating wastewater was 197.55 mg / L, the concentration of calcium was 52.9 mg / L, and the concentration of magnesium was 31.4 mg / L;

[0044] b. Pretreatment of weak acid ion exchange fibers: 1.39g of weak acid ion exchange fibers (the weak acid ion exchange fibers are ion exchange fibers prepared according to the technical scheme of Patent No. 200410060275.0) are wet-loaded into Φ10×300mm ion exchange columns, Then use sodium hydroxide solution with a concentration of 1mol / L to wash and transform the ion exchange fiber in the column through the ion exchange column (the rate of sodium hydroxide solution passing through the column during the washing process is 1ml / (min·g)), and the ions The exchange fibers are all converted into Na-type ion exchange fibers (at this time, the pH of the effluent from the ion exchange column is >10); then the column is washed with deionized water until neutral, and the treated...

Embodiment 3

[0055] The concentration of nickel in the original nickel-containing electroplating wastewater is 30-40mg / L, the concentration of calcium is 0-10mg / L, the concentration of magnesium is 0-10mg / L, and the pH is 6-7;

[0056] b. Pretreatment of weak acid ion exchange fibers: Weigh 1.5146g of weak acid ion exchange fibers (the weak acid ion exchange fibers are ion exchange fibers prepared according to the technical scheme of patent No. 200410060275.0) and wet install them on Φ10×300mm ion exchange columns , and then use a sodium hydroxide solution with a concentration of 1mol / L to wash and transform the ion-exchange fiber in the column through the ion-exchange column (the rate of sodium hydroxide solution passing through the column during the washing process is 1ml / (min·g)), and the The ion-exchange fiber is converted into Na-type ion-exchange fiber. When the pH of the effluent is > 10, the fiber is completely converted into Na-type; then the column is washed with deionized water u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com