Integrative electroplating waste treatment process

A technology of electroplating wastewater and treatment process, which is applied in metallurgical wastewater treatment, water/sewage treatment, reduced water/sewage treatment, etc. It can solve the problems of different solubility products of heavy metal ions, high operating costs, and high investment in comprehensive electroplating wastewater treatment. Achieve the effects of saving dosage, saving investment and floor area, reducing engineering investment and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

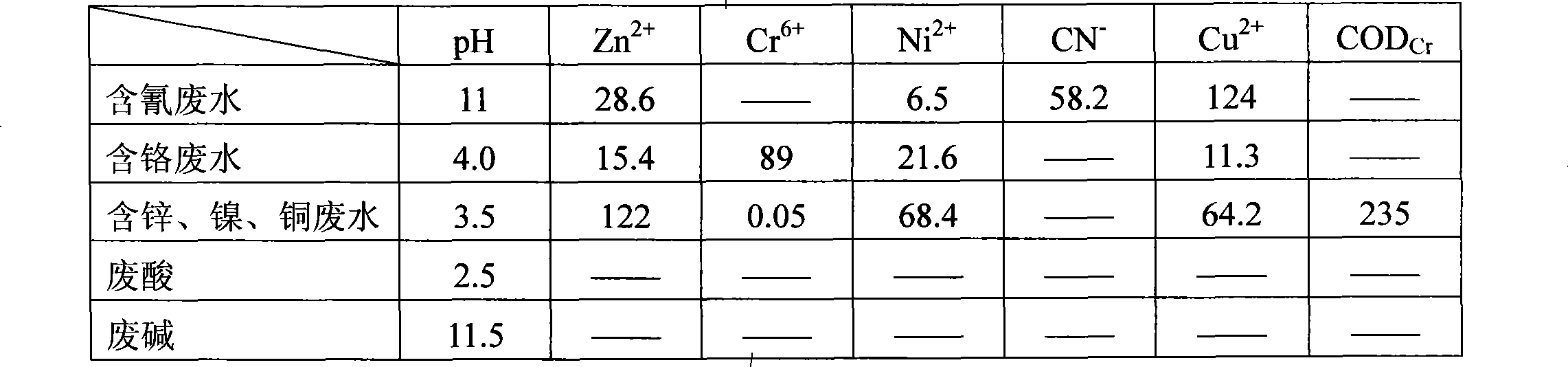

[0026] Example 1: A large-scale electroplating enterprise in Dalian Development Zone discharges 400 tons of comprehensive electroplating wastewater per day, and the influent water quality index:

[0027] Table 1 Water quality of 5 kinds of wastewater Unit: mg / L

[0028]

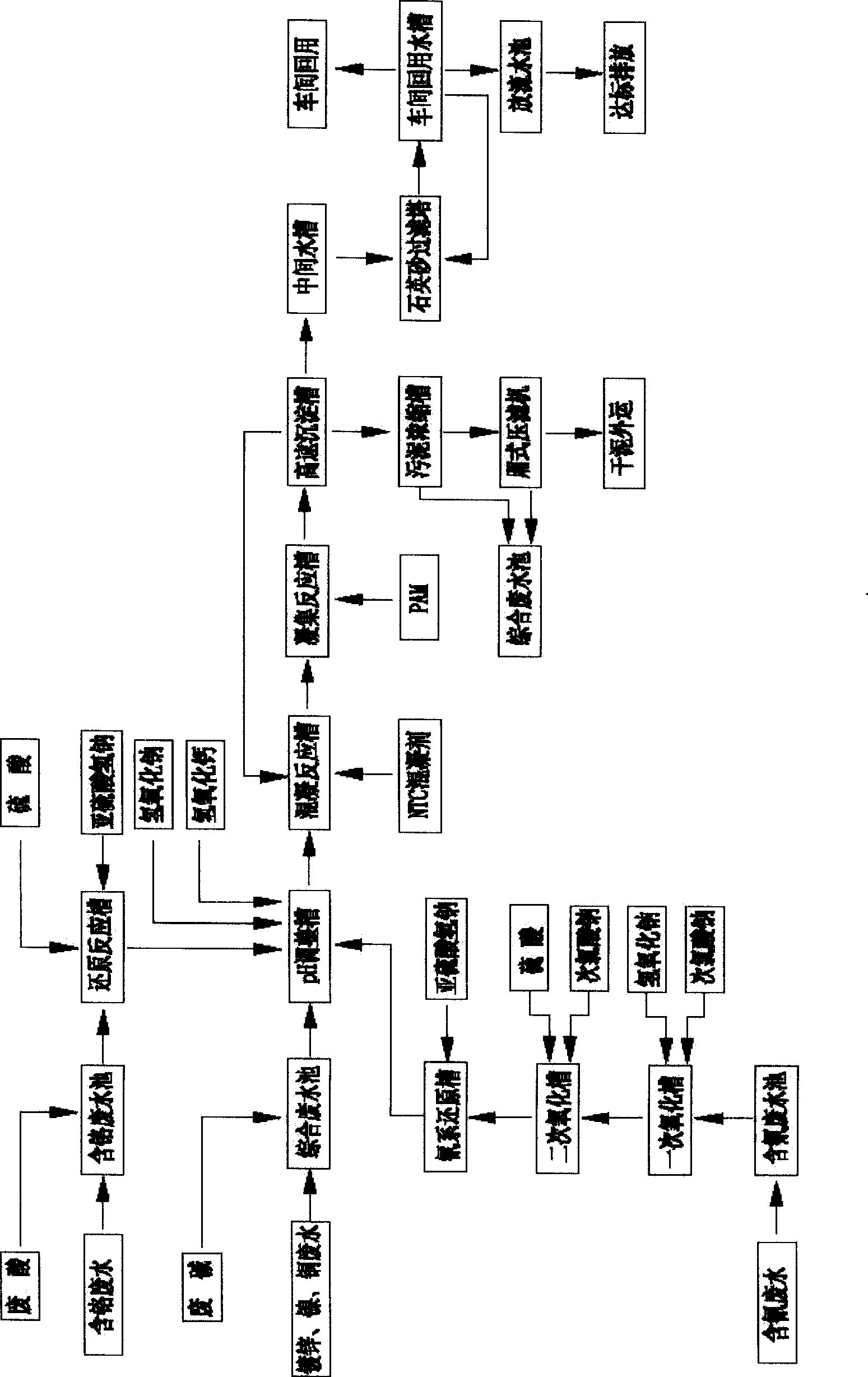

[0029] treatment techniques such as figure 1 The method shown:

[0030] 1. Comprehensive electroplating wastewater classification collection, treatment of waste acid, waste alkali

[0031] The electroplating wastewater is divided into five categories, namely wastewater containing hexavalent chromium, wastewater containing cyanide, wastewater containing zinc and copper, waste acid and alkali. Wastewater containing hexavalent chromium, wastewater containing cyanide, wastewater containing zinc, nickel, and copper are respectively built into wastewater pools, and the volume of the wastewater pool is designed to be 6-8 times the average hourly water volume of each type of wastewater, that is, the nominal hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com