A method for resource processing non-ferro metals processing wastewater containing ammonia and sulfate radical

A non-ferrous metal and sulfate technology, applied in the metal processing process, the recovery of ammonia and sodium sulfate, can solve the problems of resource loss, high equipment investment, complex treatment process, etc., to achieve the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

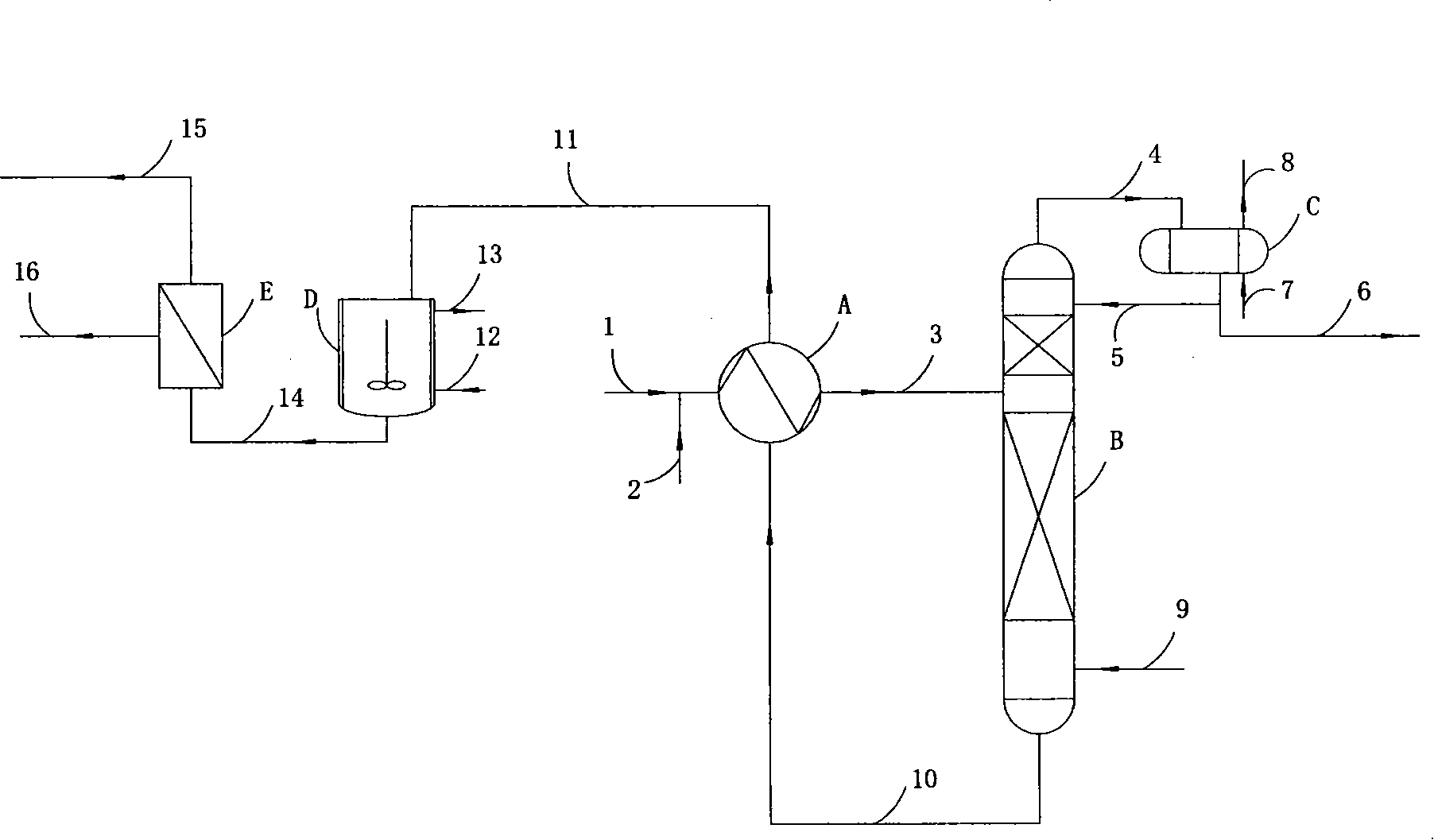

Method used

Image

Examples

Embodiment 1

[0033] The water quality of a vanadium and molybdenum catalyst processing wastewater is: ammonia nitrogen concentration 10000mg / L, sulfate concentration 139000mg / L, vanadium concentration 600mg / L, molybdenum concentration 300mg / L, pH value 2.1. During the treatment, adjust the pH of the wastewater to be treated to 12 with 45% sodium hydroxide, and then transport it to a rectification column with 1 theoretical plate in the rectification section and 10 theoretical plates in the stripping section. Rectification is carried out under 1 atmospheric pressure, and the gas at the top of the tower is condensed into a liquid at 45°C, 20% of which is refluxed, and the remaining 80% is collected as a product; the water in the tower kettle enters the cooling crystallization reactor after being cooled down, and in the cooling crystallization reactor , the liquid temperature was lowered to 1°C, and the mixture was filtered after 5 hours to obtain sodium sulfate crystals and treated water. The...

Embodiment 2

[0035] The water quality of a vanadium-containing industrial waste residue processing wastewater is: ammonia nitrogen concentration 14000mg / L, sulfate concentration 103000mg / L, vanadium concentration 460mg / L, pH value 8.7. During the treatment, adjust the pH of the waste water to be treated to 12.5 with 45% sodium hydroxide, and then transport it to a rectification column with 5 theoretical plates in the rectification section and 20 theoretical plates in the stripping section. Distillation treatment, the top gas is condensed into liquid at 5°C, 70% of which is refluxed, and the remaining 30% is collected as a product; the water in the tower kettle enters the cooling crystallization reactor after cooling treatment, and the liquid temperature is lowered in the cooling crystallization reactor After 5 hours at 7°C, the mixture was filtered to obtain sodium sulfate crystals and treated water. Analysis shows that the water quality indicators after treatment are as follows: ammonia n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com