Direct quenching technology suitable for steel plates with different thicknesses and high durability

A technology for toughened steel plates and steel plates, applied in the field of on-line direct quenching of steel plates, can solve the problems of shortening the process flow, high cost, large investment, etc., and achieve the effect of saving energy, low cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

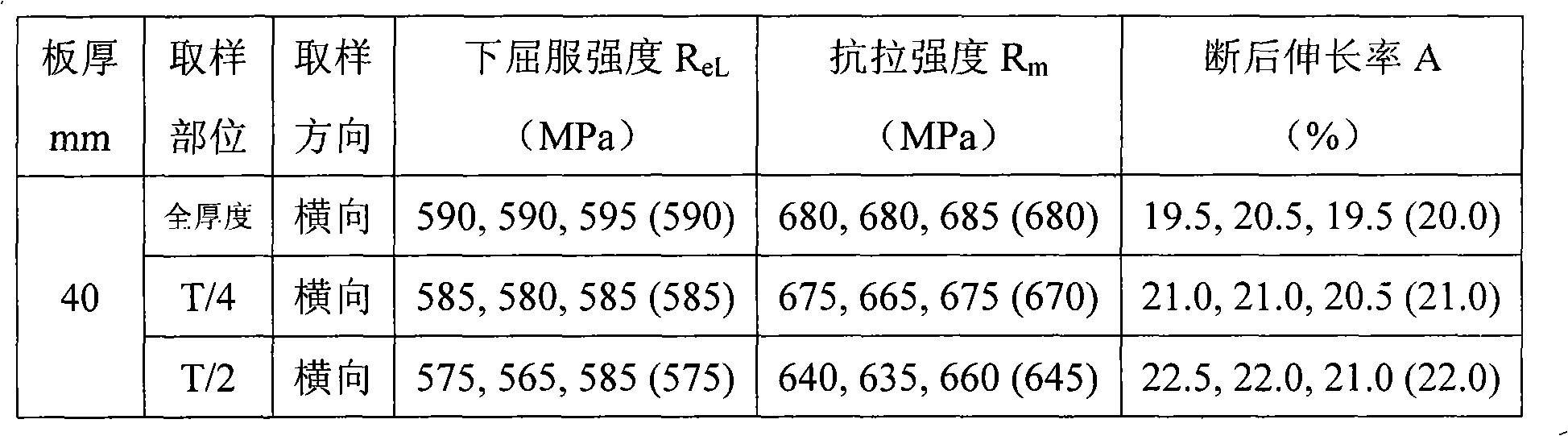

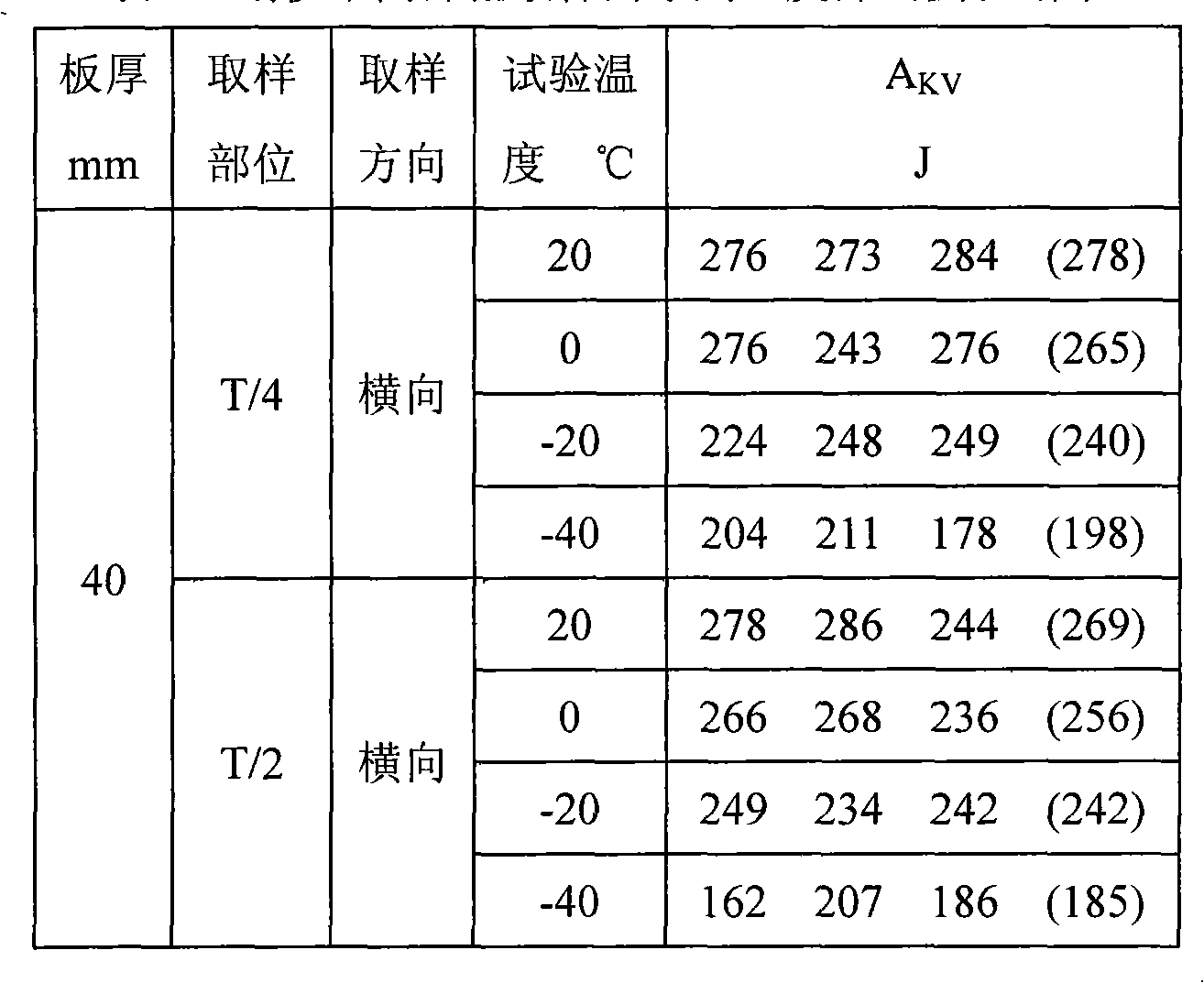

Embodiment 1

[0023] The composition of the steel plate is C: 0.09%, Si: 0.22%, Mn: 1.4%, V: 0.05%, Ti: 0.014%, P: 0.009%, S: 0.0025%. The thickness of the slab is 220mm. The slab is heated to 1230°C. After the slab is rolled by the rough rolling mill and the finishing mill, the austenite grains are fully refined. After the steel plate is rolled, it quickly enters the ACC at high temperature for on-line direct quenching. During the whole process, the cooling speed and final cooling temperature required by the process are precisely controlled by the computer, so that the steel plate can achieve the effect of online direct quenching. In the rolling process, the final rolling temperature of the steel plate is specially controlled to achieve the best cooperation between rolling and cooling. The steel plate after direct quenching is properly tempered to fully achieve the effect of quenching and tempering treatment.

[0024] Rolling process: the rough rolling start temperature is 1160°C, the ro...

Embodiment 2

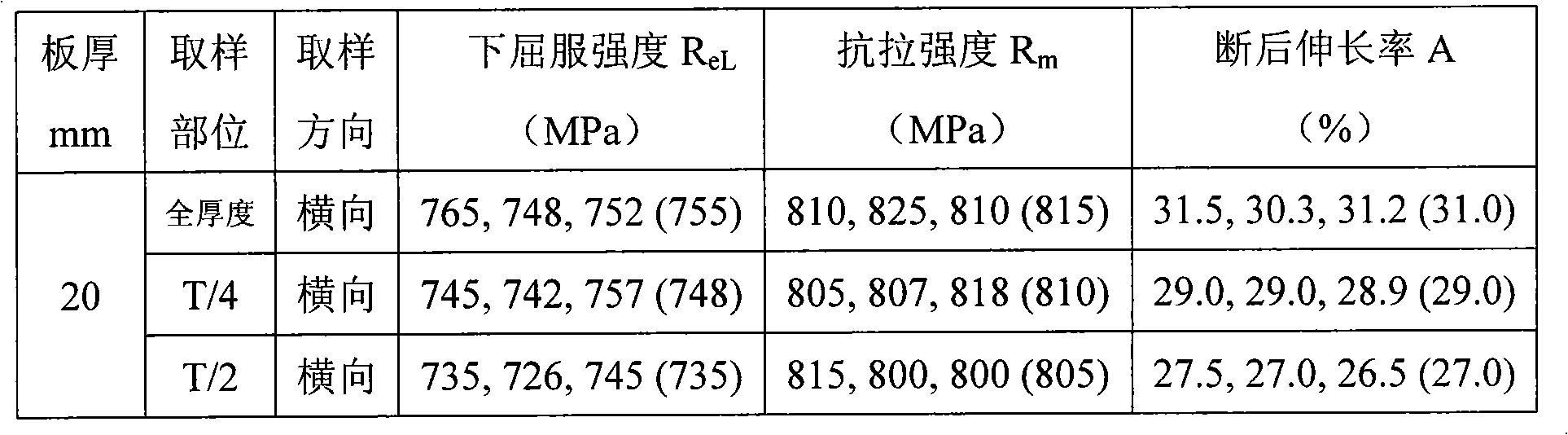

[0033] The composition of the steel plate is C: 0.05%, Si: 0.26%, Mn: 1.74%, Ni: 0.3%, Mo: 0.25%, Nb: 0.054%, Ti: 0.012%, P: 0.010%, S: 0.003%. The thickness of the slab is 150mm. The slab is heated to 1220°C. After the slab is rolled by the rough rolling mill and the finishing mill, the austenite grains are fully refined. After the steel plate is rolled, it quickly enters the ACC at high temperature for on-line direct quenching. During the whole process, the cooling speed and final cooling temperature required by the process are precisely controlled by the computer, so that the steel plate can achieve the effect of online direct quenching. In the rolling process, the final rolling temperature of the steel plate is specially controlled to achieve the best cooperation between rolling and cooling. The steel plate after direct quenching is properly tempered to fully achieve the effect of quenching and tempering treatment.

[0034] Rolling process: the rough rolling start temper...

Embodiment 3

[0043] The composition of the steel plate is C: 0.17%, Si: 1.3%, Mn: 1.55%, Ni: 0.10%, Nb: 0.054%, Ti: 0.012%, P: 0.010%, S: 0.003%. The thickness of the slab is 80mm. The slab is heated to 1220°C. After the slab is rolled through the rough rolling mill and the finishing mill, the austenite grains are fully refined. After the steel plate is rolled, it quickly enters the ACC at high temperature for on-line direct quenching. During the whole process, the cooling speed and final cooling temperature required by the process are precisely controlled by the computer, so that the steel plate can achieve the effect of online direct quenching. In the rolling process, the final rolling temperature of the steel plate is specially controlled to achieve the best cooperation between rolling and cooling. The steel plate after direct quenching is properly tempered to fully achieve the effect of quenching and tempering treatment.

[0044] Rolling process: the rough rolling start temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com