Method for recycling steel slag of LF (Low Frequency) furnace

A technology for furnace steel and steel slag, which is applied in the field of metallurgical industrial waste slag recycling, which can solve the problems of increasing the difficulty of desulfurization in the smelting process and reducing production efficiency, and achieves the effects of reducing energy consumption, reducing consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

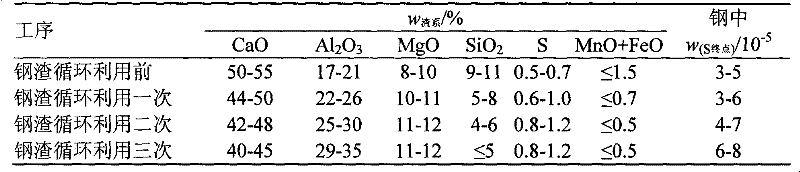

[0020] The LF steel slag obtained from the steel mill, after cooling, crushing, magnetic separation, and screening, chemical analysis shows that the composition is CaO 41%, Al 2 o 3 35%, MgO 10%, SiO 2 5%, S 0.8%, MnO+FeO 0.3%. In order to obtain the chemical composition CaO 42%, Al 2 o 3 36%, MgO 10%, SiO 2 5%, S<0.05%, MnO+FeO<0.5% pre-melted refining slag. After adding 3.5% limestone with a purity of 90% in an external way, heat the steel slag to 1300°C with air as the oxidizing gas and keep it warm for 2 hours to remove the sulfur in the slag to less than 0.05%, and then continue to heat up to make the slag composition uniform , the premelted refining slag whose composition fully meets the requirements can be obtained.

Embodiment 2

[0022] The LF steel slag obtained from the steel mill, after cooling, crushing, magnetic separation, and screening, chemical analysis shows that the composition is CaO 41%, Al 2 o 3 35%, MgO 12%, SiO 2 5%, S 0.8%, MnO+FeO 0.3%. To obtain the chemical composition CaO 41%, Al 2 o 3 35%, MgO 10%, SiO 2 6%, S<0.1%, MnO+FeO<0.5% pre-melted refining slag. After adding 50% lime containing 90% CaO and 5% magnesia containing 90% MgO and mixing them evenly, the steel slag is heated to 1250°C with air as the oxidizing gas and kept for 1 hour to remove the sulfur in the slag to less than 0.1%, and then continue to raise the temperature to make the composition of the slag uniform, and the premelted refining slag whose composition fully meets the requirements can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com