Method for simultaneously preparing charcoal, gas and liquid products from crop straw and application thereof

A technology of crop straw and products, which is applied in the manufacture of biofuels, pyroligneous acid, and special forms of dry distillation, etc., can solve problems such as poor economic benefits, and achieve the effects of improving soil physical and chemical properties, improving soil fertility, and increasing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

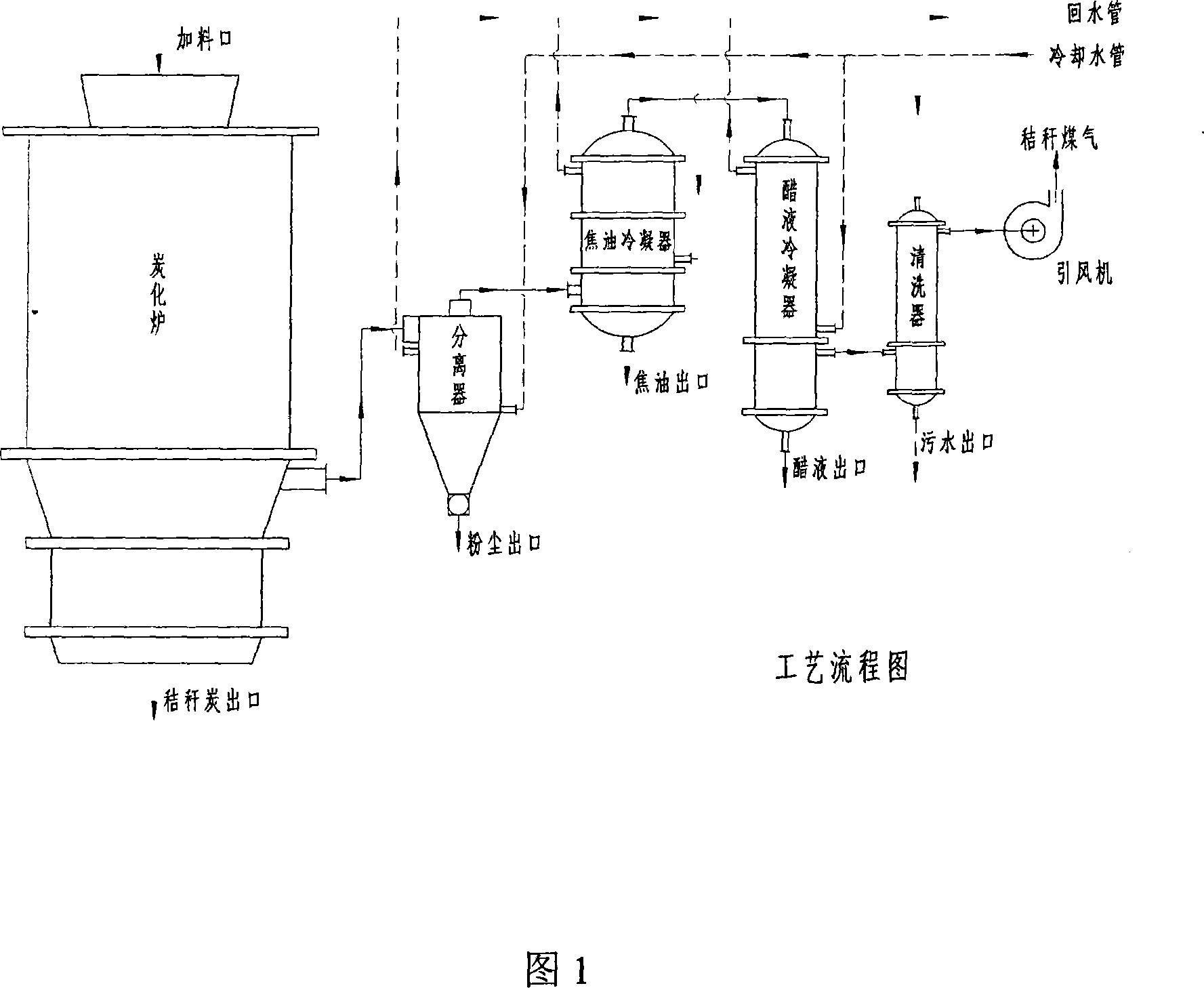

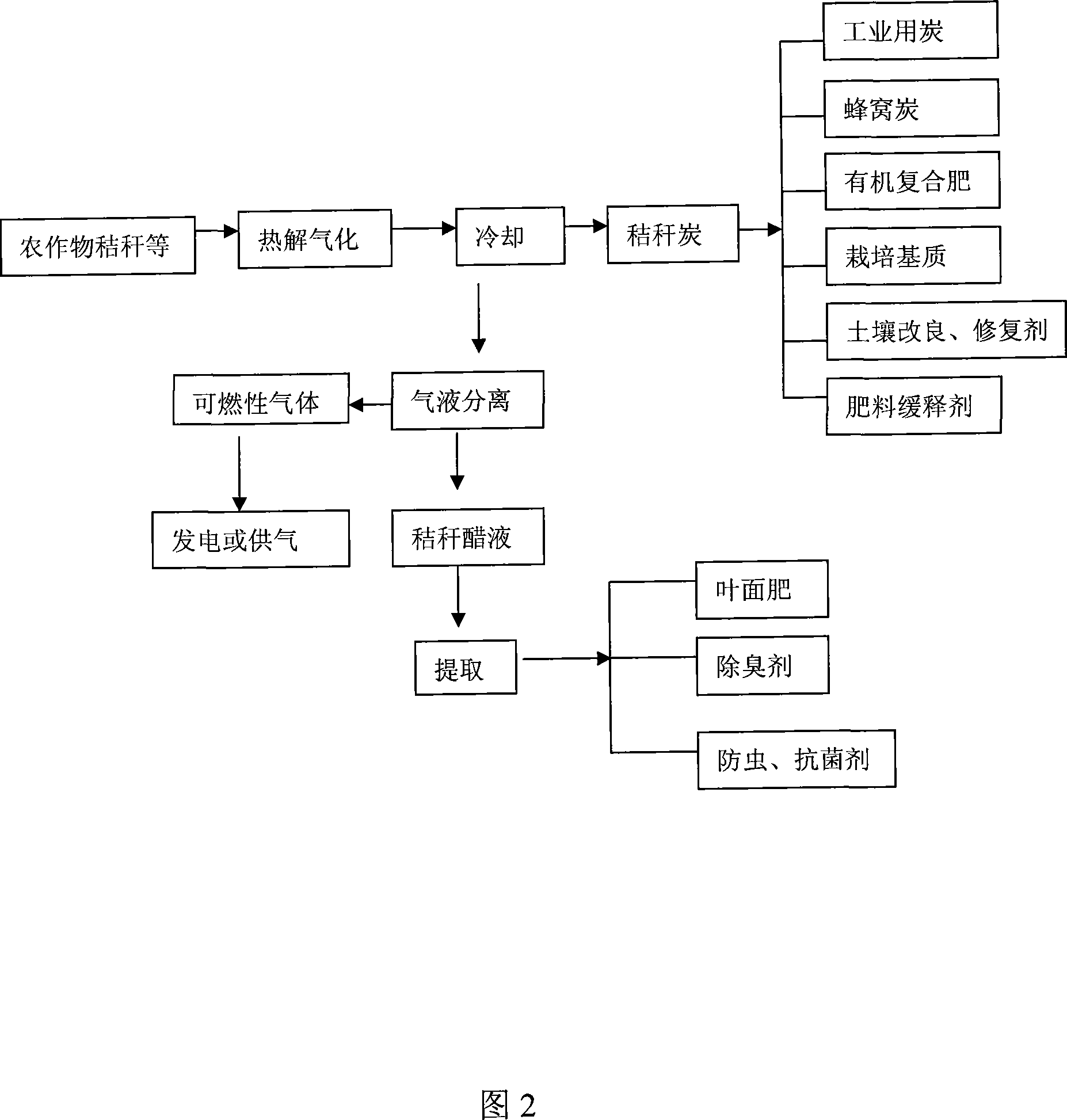

Method used

Image

Examples

Embodiment 1

[0013] The rice straw is crushed into 1~3cm according to the mass ratio of 2:1 (the ratio can be adjusted according to the needs) and mixed with the rice husk to obtain the mixed straw raw material, which is sent to the gasifier to supply oxygen in a limited amount, so that the straw is gasified to form a large amount of combustible The gas can be used to drive the gas turbine to generate electricity or supply gas. It can supply 600kg of mixed straw raw materials per hour, which can generate 300-500kw of electricity. Due to the limited amount of oxygen supply, it is 5000-12000m 3 / h, the combustion is not complete, a large amount of straw charcoal is formed when the straw is gasified, and 200-300kg of straw charcoal is produced per hour (the carbon content can reach 30-50%). It is rich in nitrogen, phosphorus, potassium and other nutrients necessary for crop growth. It can be made into organic compound fertilizer, which can effectively improve soil fertility. It has a long-term...

Embodiment 2

[0016] The straw is crushed into 1-3cm raw materials and sent to the gasifier, and a limited amount of oxygen is supplied to gasify the straw to form a large amount of flammable gas, which drives the gas turbine to generate electricity, and supplies 500-600kg of straw raw materials per hour, which can generate electricity of 300~ 500kw, due to the limited amount of oxygen supply, it is 5000~12000m 3 / h, the combustion is not complete, and a large amount of straw charcoal is formed when the straw is gasified, producing 220-320kg straw charcoal (the carbon content can reach 35-55%). It is rich in nitrogen, phosphorus, potassium and other nutrients necessary for crop growth. It can be made into organic compound fertilizer, which can effectively improve soil fertility. It has a long-term slow-release effect on water and fertilizer. Long-term application can improve soil physical and chemical properties, increase The water content and air permeability of the soil can improve and re...

Embodiment 3

[0019] Crumble the corn stalks into 1-3cm straw raw materials and feed them into the gasifier, and supply oxygen in a limited amount to gasify the straws to form a large amount of flammable gas, which drives the gas turbine to generate electricity, and supplies 550-600kg of mixed straw raw materials per hour. It can generate 300~500kw of electricity, and because it is a limited amount of oxygen supply, it is 5000~12000m 3 / h, the combustion is not complete, a large amount of straw charcoal is formed when the straw is gasified, and 210-310kg of straw charcoal is produced per hour (the carbon content can reach 30-50%). It is rich in nitrogen, phosphorus, potassium and other nutrients necessary for crop growth. It can be made into organic compound fertilizer, which can effectively improve soil fertility. It has a long-term slow-release effect on water and fertilizer. Long-term application can improve soil physical and chemical properties, increase The water content and air permea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com