Double-membrane treatment method of iron and steel industrial wastewater

A technology for iron and steel industry and membrane treatment, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of not meeting demineralized water standards, reduce fresh water consumption, reduce The effect of draining water per ton of steel and improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

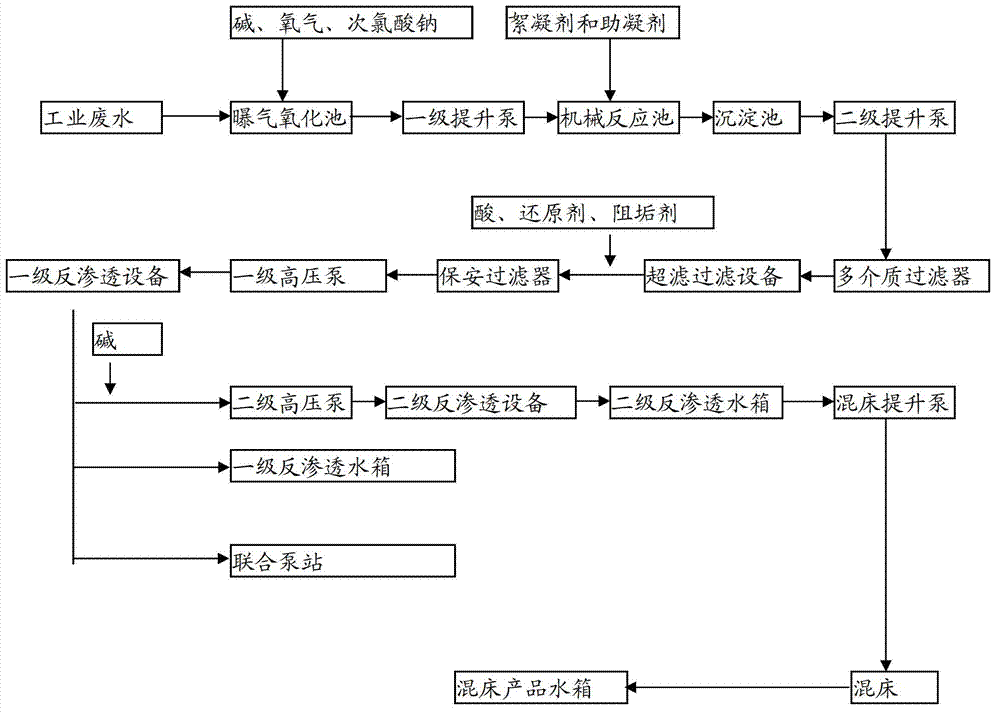

Method used

Image

Examples

Embodiment 1

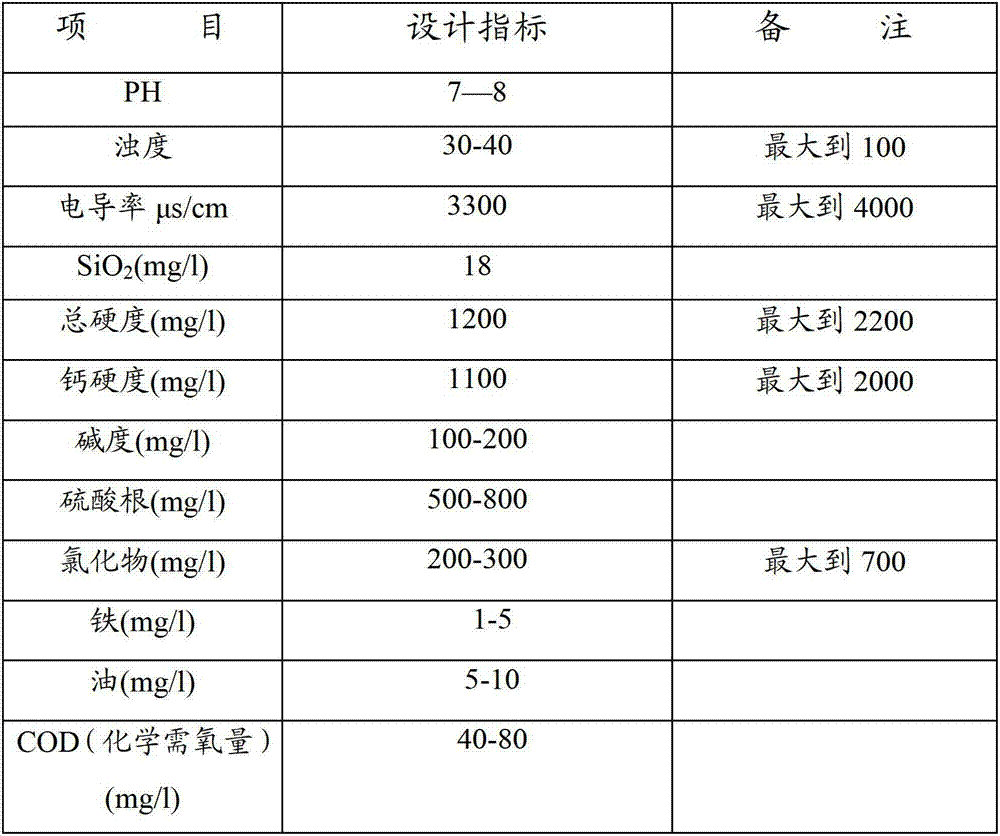

[0137] The waste water used in the embodiment is the mixed water of the rolling area and smelting waste water of Taiyuan Iron and Steel Plant, and the specific parameters are shown in Table 1.

[0138] Table 1

[0139]

[0140] (The maximum above means that the indicator value will appear in a short time)

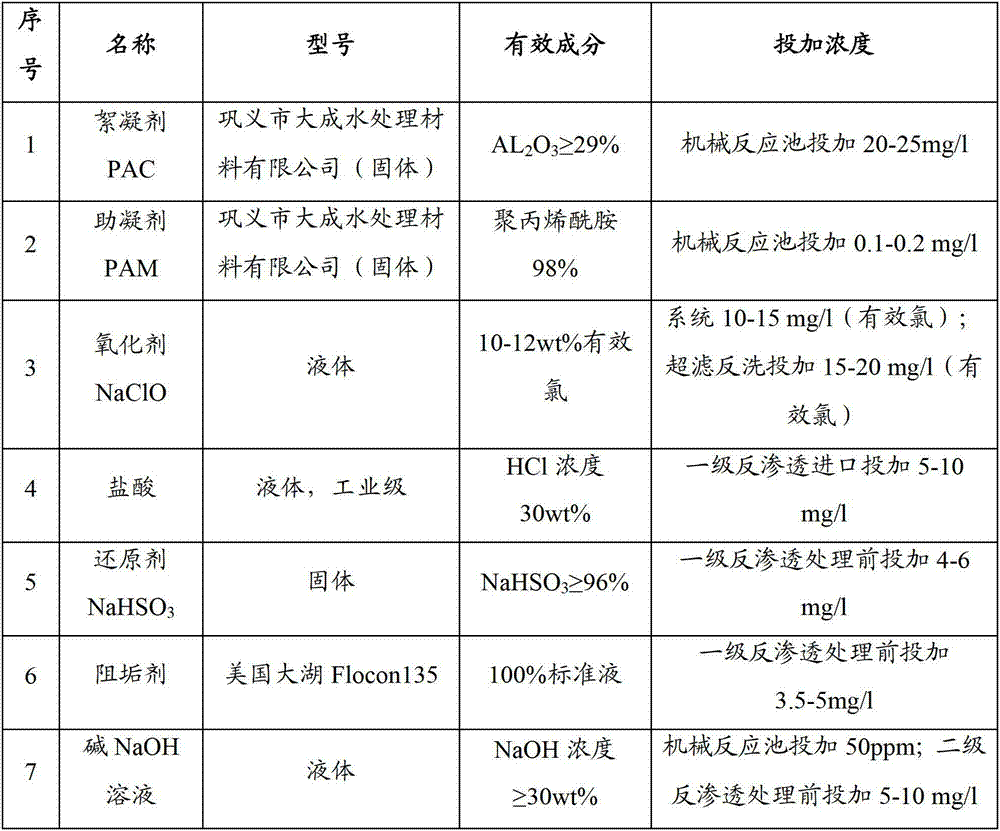

[0141] The performance index and addition situation of each auxiliary agent used in the embodiment are shown in Table 2

[0142] Table 2

[0143]

[0144] Adopt PLC to realize automatic control to each working procedure of this embodiment.

[0145] 1. Pretreatment

[0146] The wastewater in the storage tank is pumped into the aerated oxidation tank. Set up a grille at the water intake of the reservoir to intercept large floating objects in the waste water. In the aerated oxidation tank, a sodium hydroxide solution with a concentration of 30wt% is added to the wastewater to adjust the pH value of the wastewater to greater than 7. Then, adopt the conventional air ae...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com