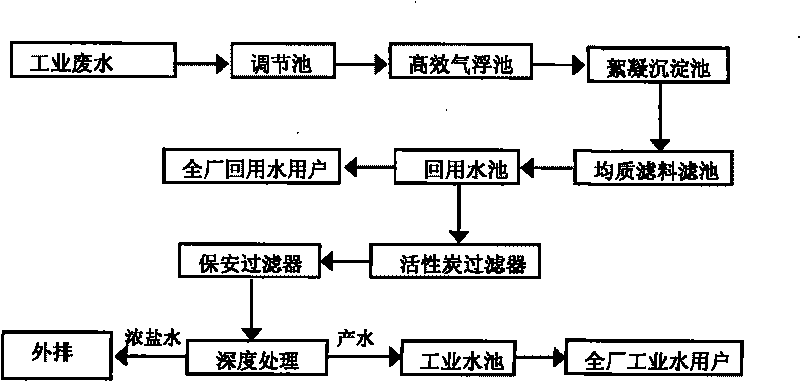

Zero-discharge treatment process for industrial wastewater of iron and steel plant

A technology for treating process and industrial wastewater, applied in the field of water supply and drainage in the iron and steel industry, can solve the problems of receiving water pollution, and achieve the effect of zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0015] A planned 10-million-ton steel plant that has reached the international advanced level is built near the sea. Since there are national key marine aquaculture bases and tourist resorts nearby, it is required to achieve zero discharge of steel industry wastewater.

[0016] Main design parameters:

[0017] New water consumption per ton of steel: 3.9 tons of water / ton of steel

[0018] New water production scale: 160,000 tons / day

[0019] The amount of industrial wastewater in the whole plant: 25,000 tons / day

[0020] Industrial wastewater advanced treatment capacity: 10,000 tons / day

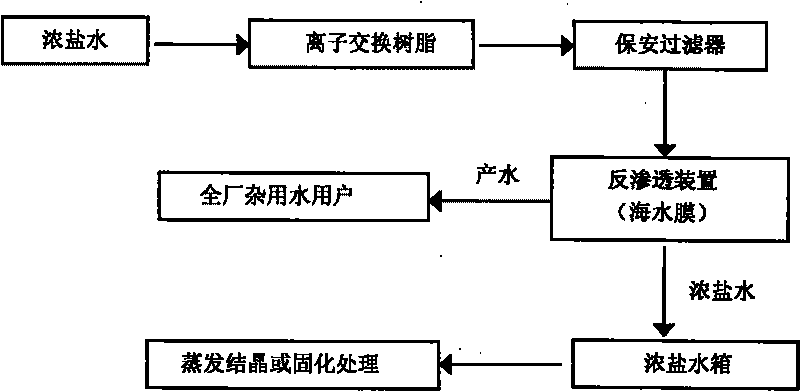

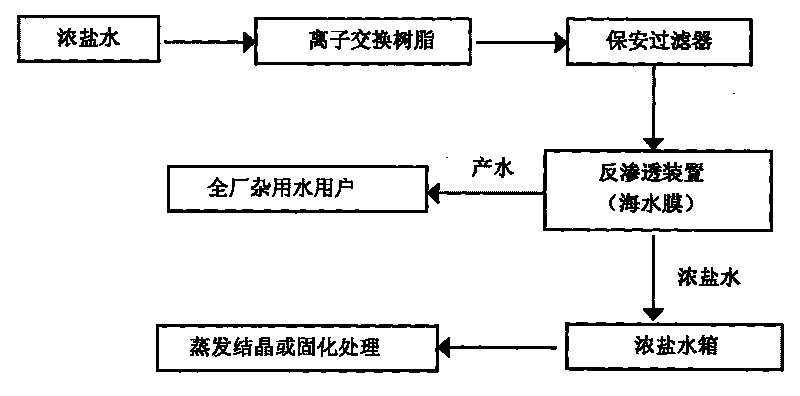

[0021] Through the water balance analysis software of the whole plant, analyze the water consumption per ton of product and per ton of steel for each production unit included in the iron and steel plant, and determine the international advanced new water consumption per ton of steel index of 3.9 tons of water / ton of steel. According to the characteristics of good raw water quality, the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com